Hydrostatic valve arrangement, hydrostatic transmission gear having valve arrangement, and hydrostatic drive device having transmission gear

A technology of transmission mechanism and valve device, which is applied in the direction of transmission device control, valve device, fluid pressure actuation device, etc., and can solve problems such as component cavitation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

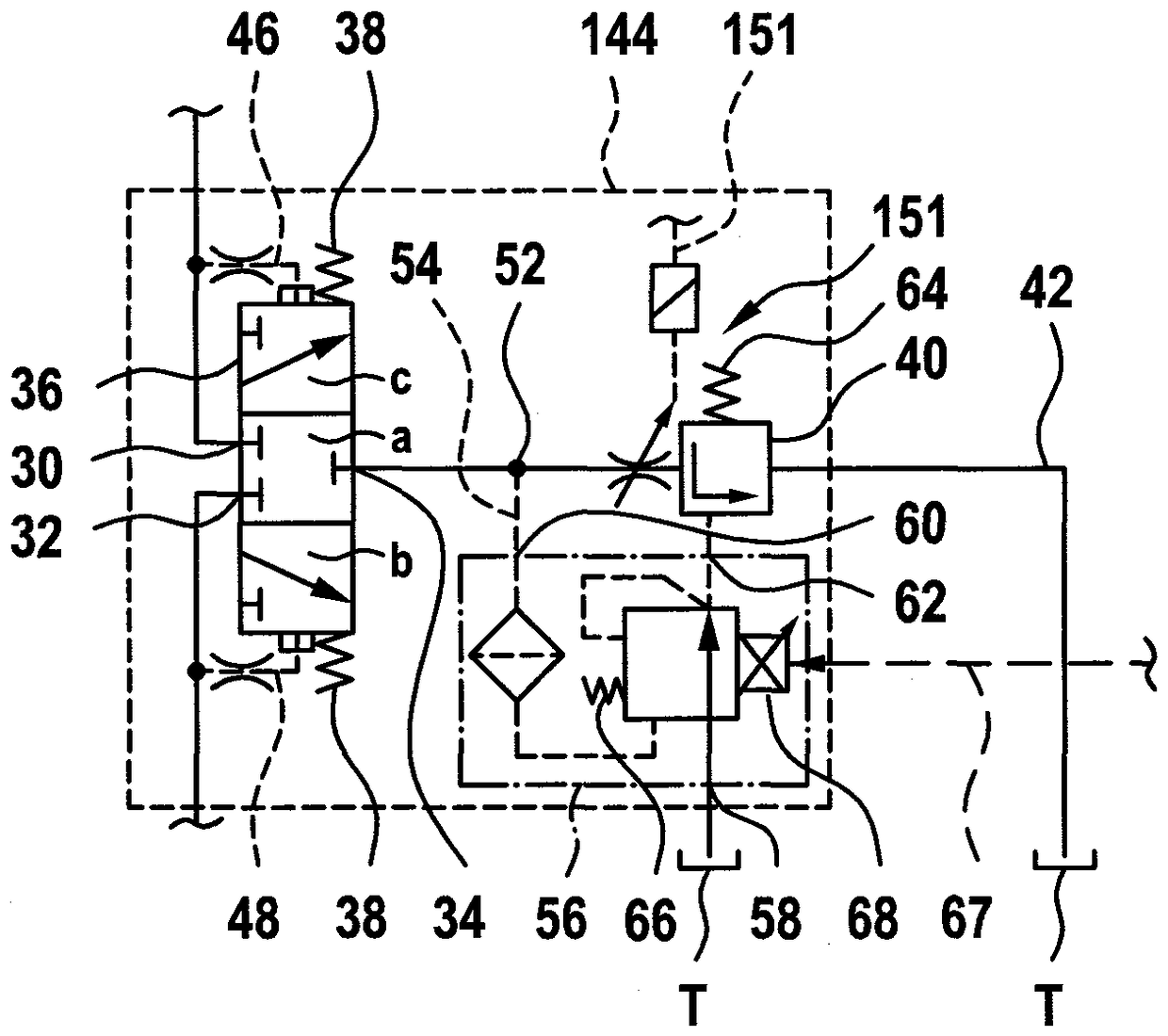

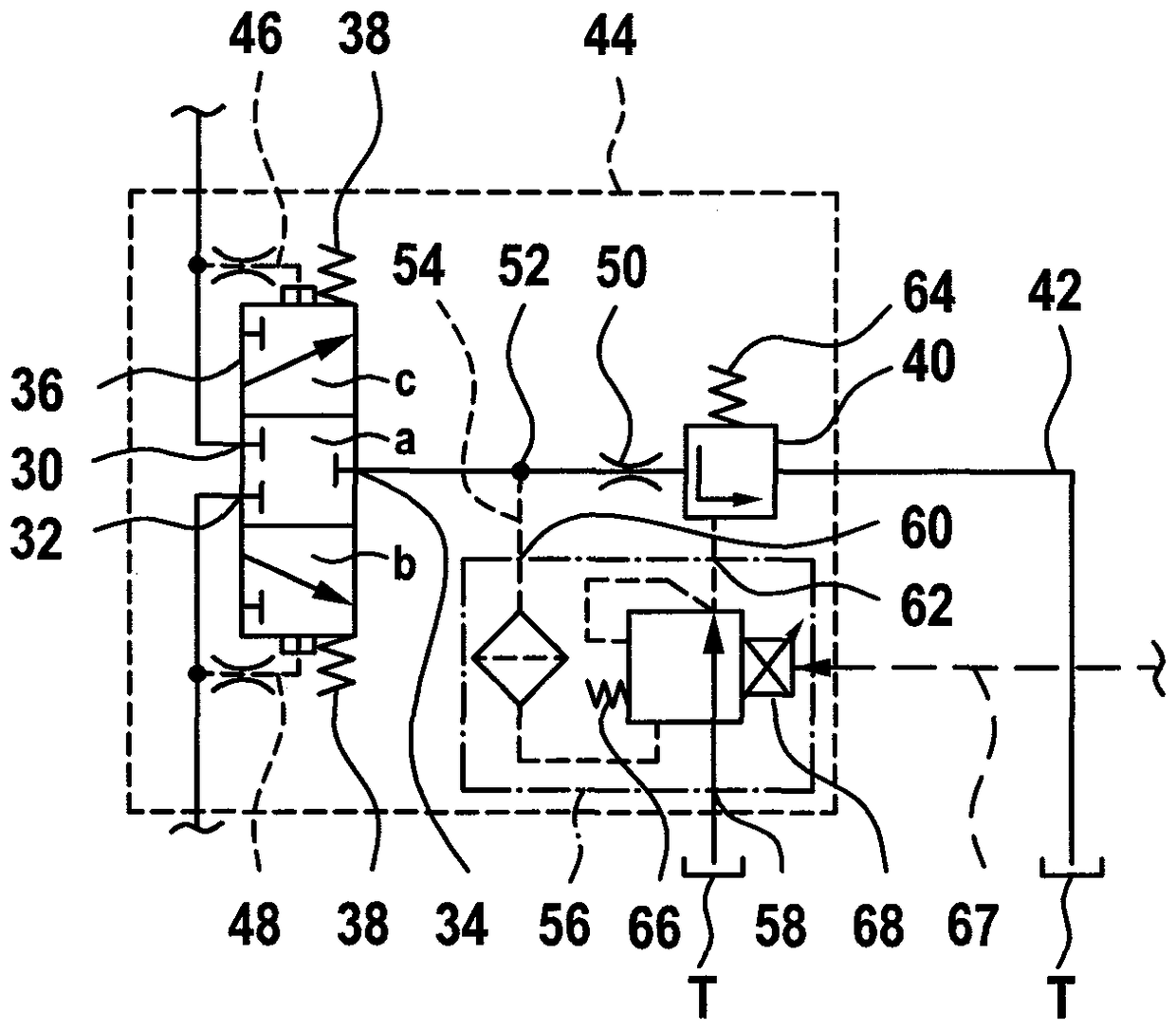

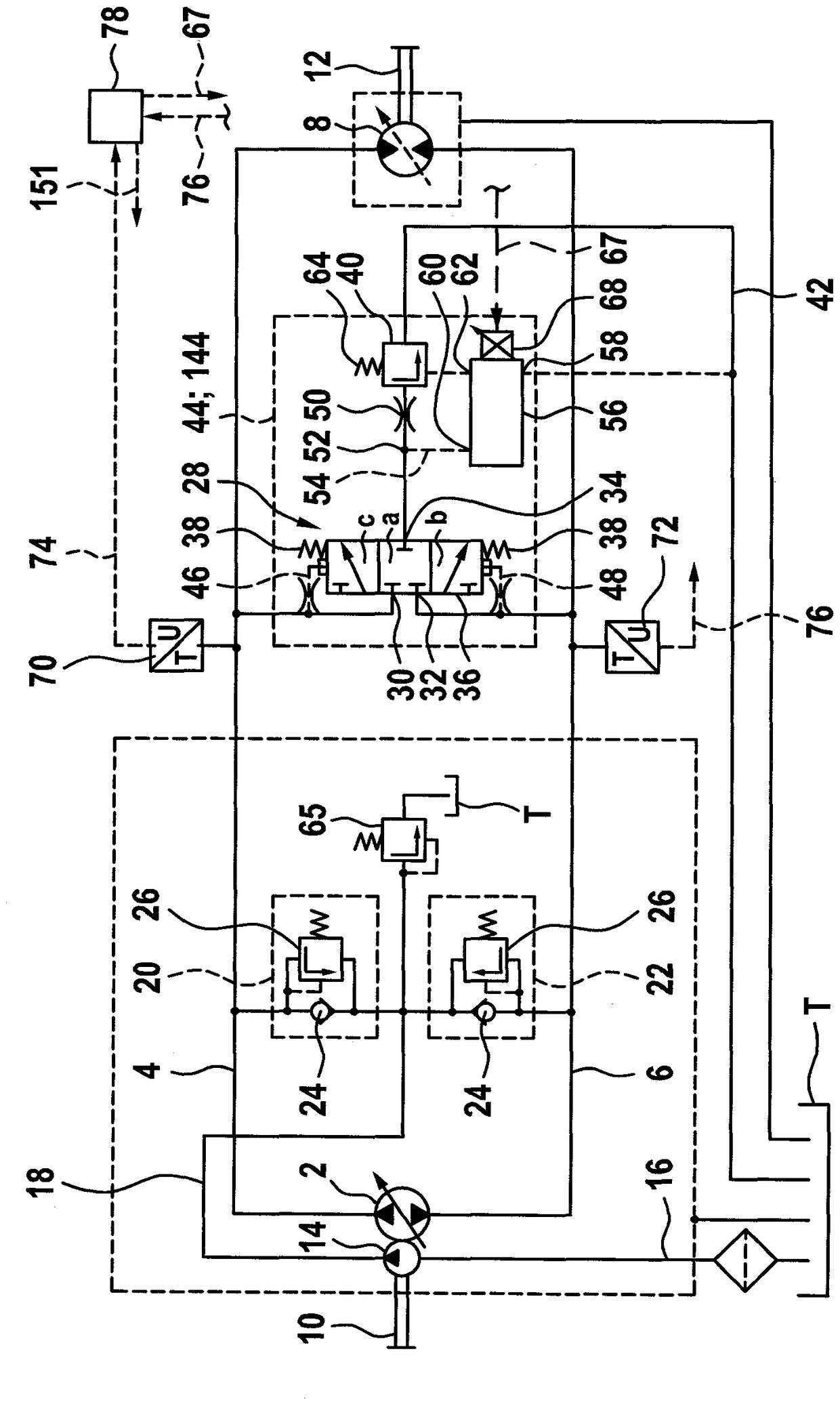

[0029] according to figure 1 , the hydrostatic transmission 1 has a first hydraulic machine 2 and a second hydraulic machine 8 connected to said first hydraulic machine in a closed hydraulic circuit via a first working line 4 and a second working line 6 , In this case, the hydrostatic drive is provided for use in a displacement device or a transport drive as described above. In the exemplary embodiment shown, the first hydraulic machine 2 or hydraulic pump 2 is designed as an axial piston machine of swash plate design with adjustable displacement. It is reversible, that is to say the swashplate whose delivery capacity is determined can be adjusted on either side of a neutral or zero position in which its delivery capacity is zero, so that the first hydromechanical The drive torque of 2, which remains the same, switches the pressure in the working lines 4, 6 and thus reverses the direction of rotation on the second hydraulic machine. To adjust its displacement, the first hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com