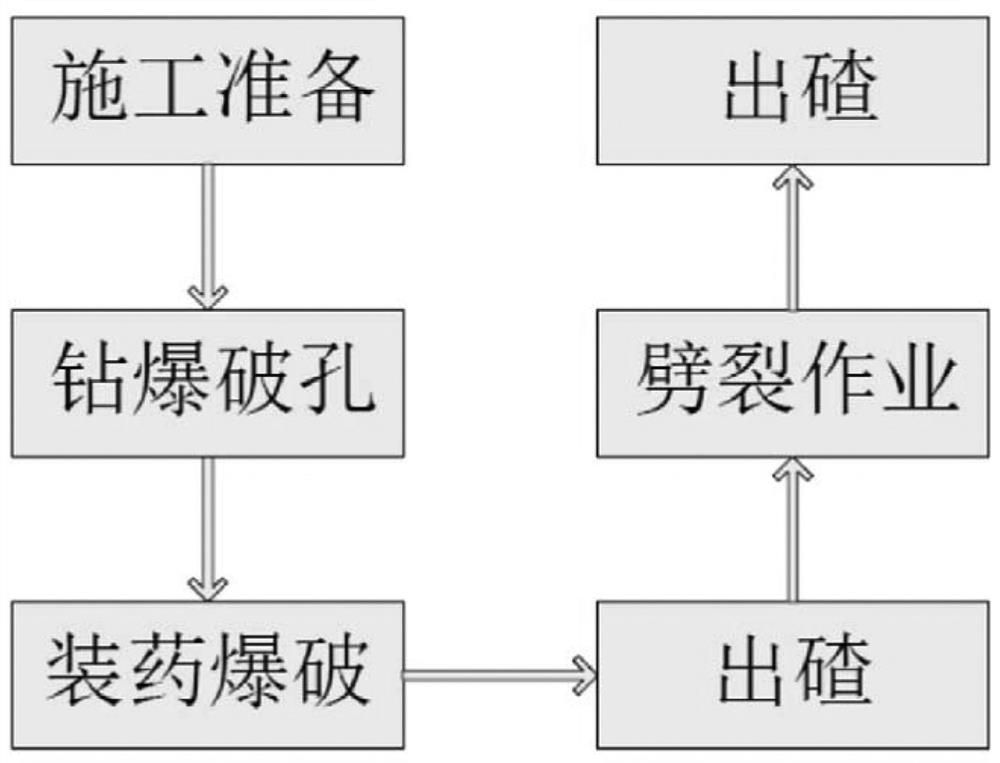

A mixed rock-breaking process of smooth blasting and split blasting

A smooth blasting and rock-breaking technology, which is applied in the field of rock-breaking technology, can solve the problems of increasing the amount of backfill concrete, disturbing the surrounding rock, and increasing the project cost, so as to achieve the effects of reducing project cost, reducing overbreak and underbreak, and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

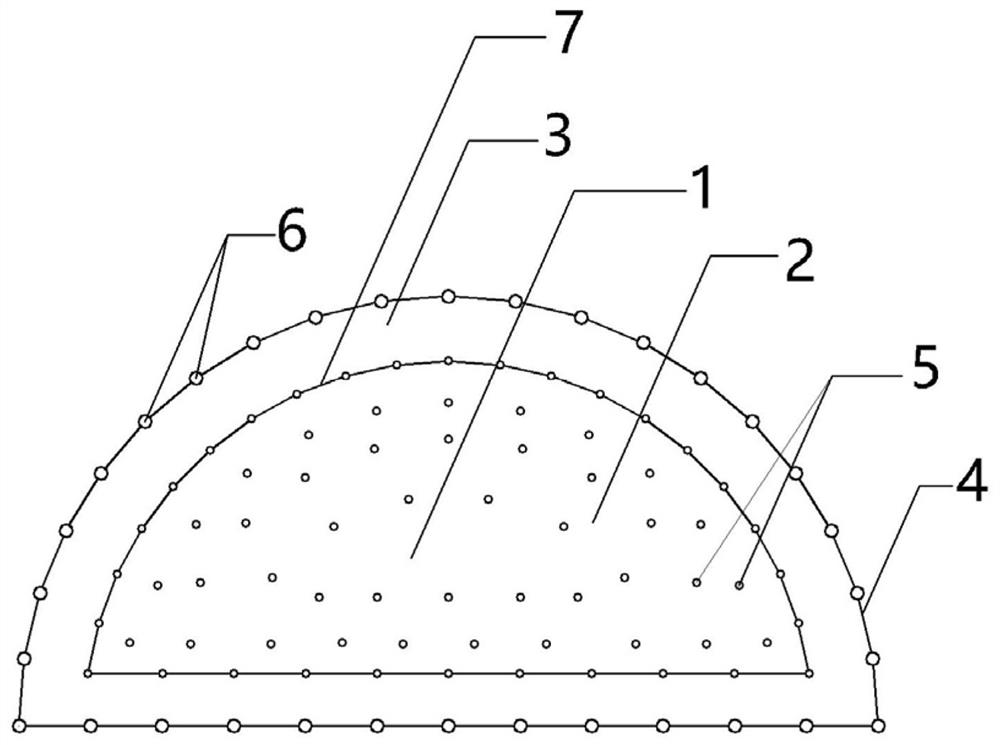

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] A rock-breaking process that combines smooth blasting and splitting blasting. The face 1 is divided into a blasting area 2 and a splitting area 3. The splitting area 3 is surrounded by the periphery of the blasting area 2. The blasting area 2 and the splitting area Between 3 is the air surface 7, and the periphery of the splitting area 3 is provided with a contour line; in the blasting area 2, a plurality of blasting holes 5 are arranged, and on the contour line 4 of the splitting area 3, a plurality of splitting holes 6 are arranged.

[0027] The blasting area 2 is provided with blasting holes 5, the diameter of the blasting holes 5 is 4.2 cm, the spacing is about 35 cm, and the hole depths are 150 cm and 300 cm. Splitting holes 6 are arranged on the contour line 4 of the splitting area 3. The diameter of the splitting holes 6 is 10-12 cm, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com