Compression test fixture for tensile testing machine

A compression test and fixture technology, applied in the direction of applying stable tension/compression to test the strength of materials, measuring devices, instruments, etc., can solve the problem that the tensile testing machine cannot do the compression test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

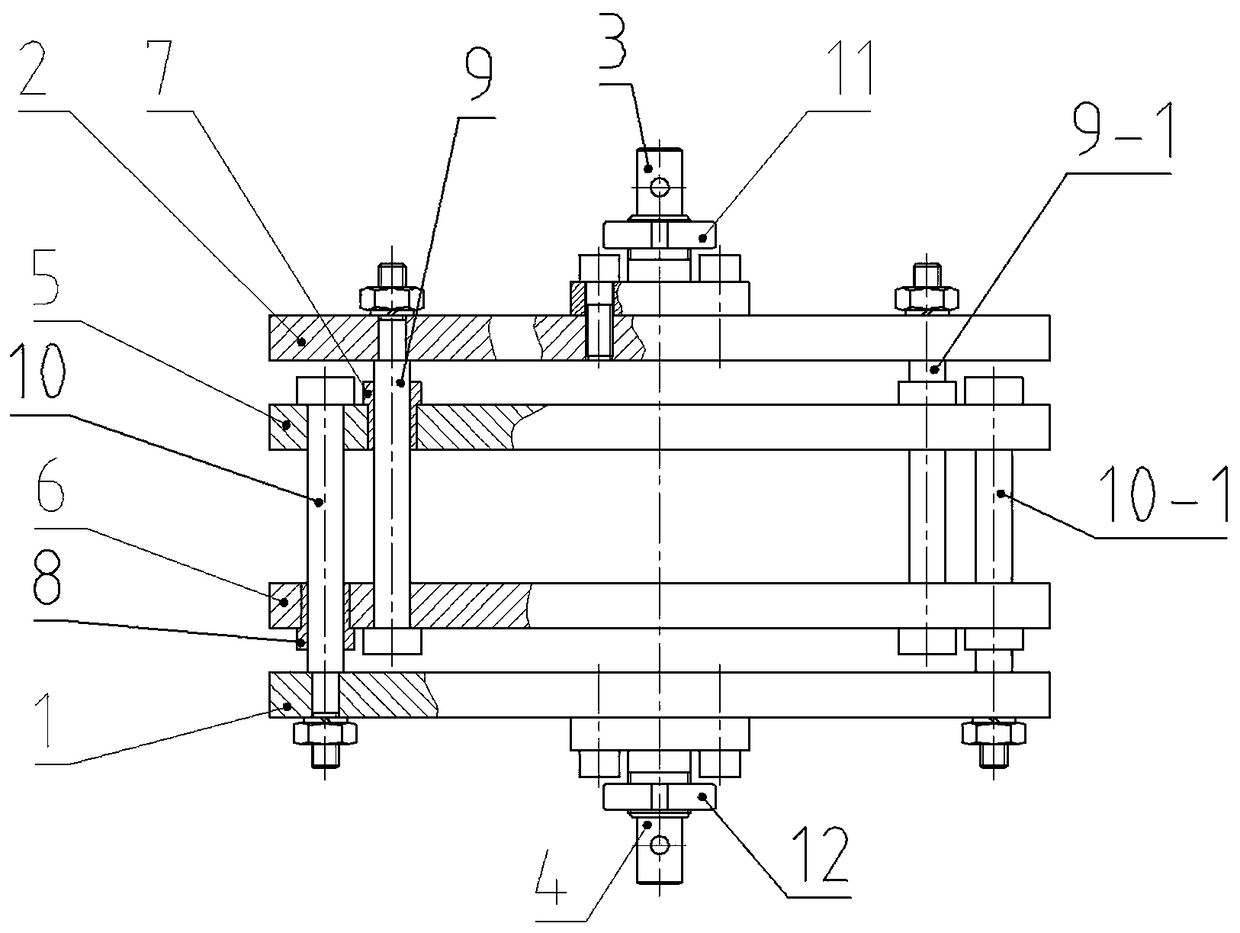

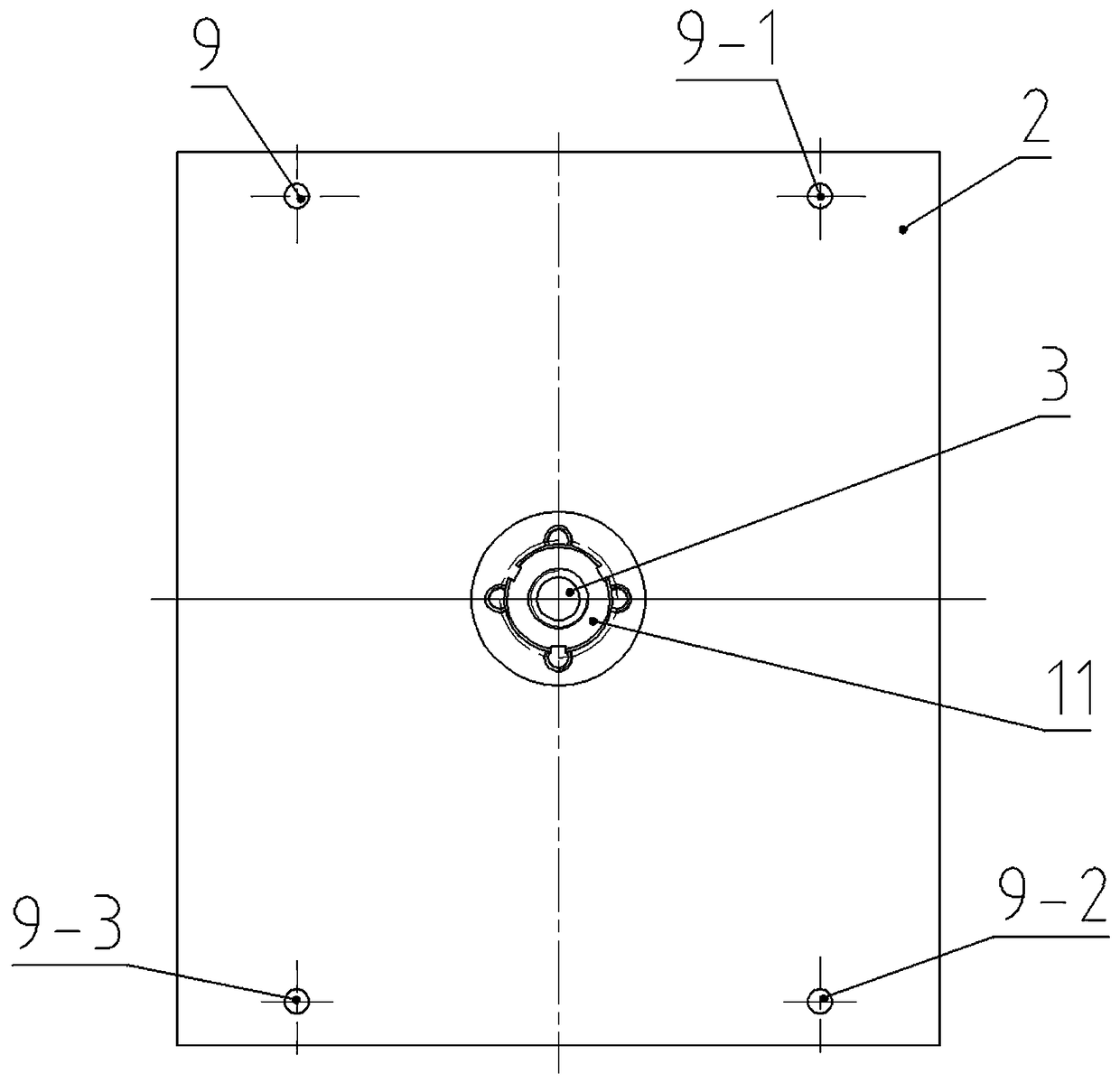

[0016] refer to figure 1 , figure 2 , a compression test fixture for a tensile testing machine, comprising an upper fixed plate 2 and a lower fixed plate 1, the center of the upper fixed plate 2 facing outward is provided with a first connector 3 with a flange, and the upper fixed plate 2 The first tie rod 9, the second tie rod 9-1, the third tie rod 9-2 and the fourth tie rod 9-3, which are symmetrical with the first connecting head 3 as the axis, are arranged on the top, and the center of the outer side of the lower fixing plate 1 There is a second connecting head 4 with a flange at the bottom, and the lower fixing plate 1 is provided with the fifth tie rod 10, the sixth tie rod 10-1, and the seventh tie rod 10-2, which are symmetrical with the second connecting head 4 as the axis. With the eighth pull rod 10-3, between the upper fixed plate 2 and the lower fixed plate 1, a parallel upper clamping plate 5 and a lower clamping plate 6 are provided, and the upper clamping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com