A solar water heater antifreeze belt life testing device and method

A technology of solar water heaters and testing devices, which is applied in measuring devices, instruments, measuring electronics, etc., can solve problems such as failure to reach the maximum temperature, increase sample test errors, and damage to antifreeze belts, and meet the requirements of life testing. The device is simple and practical, Easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

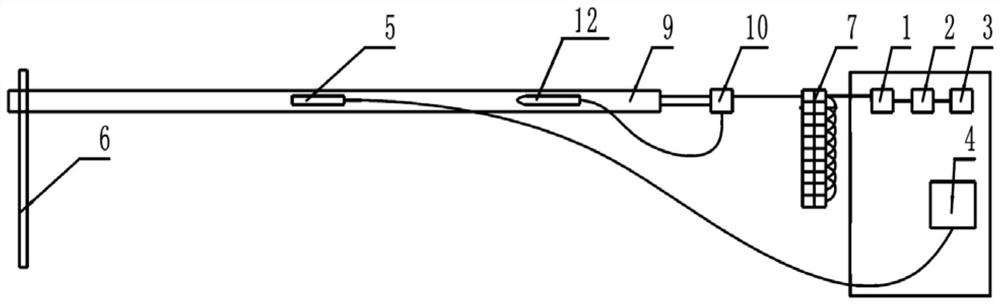

[0046] Such as figure 1 As shown, a solar water heater antifreeze belt life testing device, including a time relay 1, an electromagnetic relay 2, a counter 3, a data acquisition instrument 4, a temperature measuring resistor 5, a fixing device 6, a terminal 7, a temperature controller 10 and a temperature measuring Probe12.

[0047] One end of the terminal 7 is connected with the antifreeze belt 9, the other end is connected with the time relay 1, the time relay 1 is connected with the electromagnetic relay 2, the electromagnetic relay 2 is connected with the counter 3, and the antifreeze belt 9 is fixed on the fixture 6, The temperature measuring resistor 5 is arranged on the heat dissipation surface of the antifreeze belt 9; the data acquisition instrument 4 is connected with the temperature measuring resistor 5; the temperature controller 10 is arranged on the wire between the terminal 7 and the antifreeze belt 9, And the temperature controller 10 is connected with the tem...

Embodiment 2

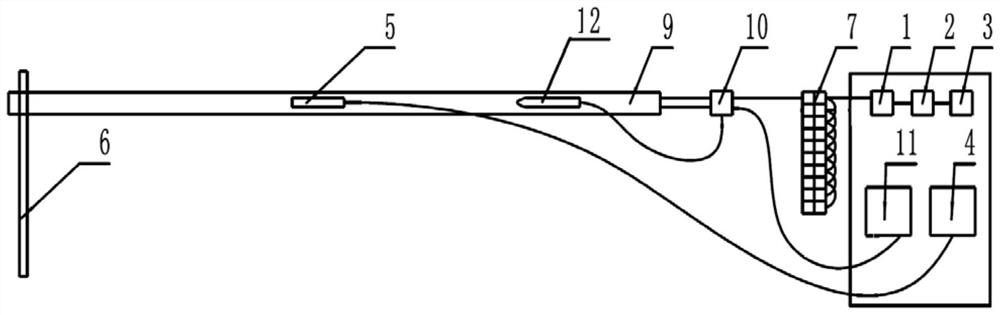

[0049] Such as figure 2 As shown, a solar water heater antifreeze belt life test device is the same as in Example 1, the difference is that the test device also includes a computer, the computer is connected to a thermostat, and the temperature of the antifreeze belt detected by the computer through a temperature measuring probe is the same as The preset safe temperature upper limit is compared. Once the temperature of the antifreeze belt exceeds the safe temperature upper limit, the thermostat is immediately controlled to disconnect to protect the safety of the entire test system.

Embodiment 3

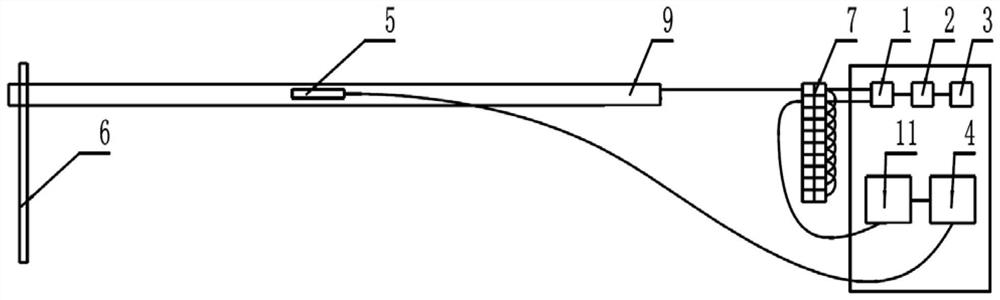

[0051] Such as image 3 As shown, a solar water heater antifreeze belt life testing device includes a time relay 1, an electromagnetic relay 2, a counter 3, a data acquisition instrument 4, a temperature measuring resistor 5, a fixing device 6, a terminal 7 and a computer 11.

[0052] One end of the terminal 7 is connected with the antifreeze belt 9, the other end is connected with the time relay 1, the time relay 1 is connected with the electromagnetic relay 2, the electromagnetic relay 2 is connected with the counter 3, and the antifreeze belt 9 is fixed on the fixture 6, The temperature measuring resistor 5 is arranged on the cooling surface of the antifreeze belt 9; the data acquisition instrument 4 is connected with the temperature measuring resistor 5; the time relay 1 is connected with the computer 11 through the terminal 7, and the computer 11 and the data acquisition Instrument 4 is connected.

[0053] In this way, first of all, the computer can make full use of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com