A kind of hydraulic system and test method of outrigger hydraulic cylinder imitation working condition test bench

A technology of hydraulic system and test bench, applied in the field of hydraulic cylinder, can solve the problems of hydraulic cylinder chattering, low control precision, oil leakage, etc., and achieve the effect of precise load application, high control precision and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

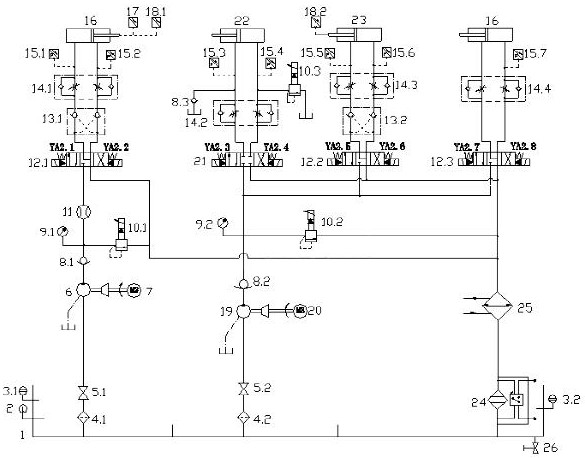

[0063] A test method for an outrigger hydraulic cylinder imitation working condition test bench, on the basis of the above-mentioned first embodiment,

[0064] Simulation test of outrigger cylinder supporting process:

[0065] All cylinders are retracted,

[0066] 1. The piston rod of the axial loading cylinder 22 protrudes by the corresponding length, and the rodless cavity pressure of the axial loading cylinder 22 is set: the YA2.4 end of the three-position four-way reversing valve IV21 is energized. Stroke, the piston rod of the axial loading cylinder 22 protrudes by the corresponding length, according to the rated load of the tested cylinder 16, the pressure of the rodless cavity of the axial loading cylinder 22 is set by the relief valve II 10.2;

[0067] 2. The cylinder under test 16 extends out of no-load and contacts with the axial loading cylinder 22, simulating that the truck crane is parked on the ground and the tires of the vehicle are on the ground: the YA2.1 end...

Embodiment 3

[0073] A test method for an outrigger hydraulic cylinder imitation working condition test bench, on the basis of the above-mentioned first embodiment,

[0074] Simulation test of lifting process of outrigger cylinder under side load:

[0075] 1. The axial loading cylinder 22 is fully retracted: the auxiliary motor 20 is powered on to start, the relief valve II 10.2 is powered on, and the YA2.3 end of the three-position four-way reversing valve IV21 is powered on, so that the axial loading cylinder 22 piston is powered on. rod retracts;

[0076] 2. The tested cylinder 16 is extended to contact the axial loading cylinder 22, the rodless chamber of the tested cylinder 16 is pressurized to the rated pressure, and the two chambers are locked. The steps are as follows: the main motor 7 is started, and the three-position four-way reversing valve I12. The YA2.1 terminal of 1 is energized, the cylinder under test 16 is extended, and the relief valve I10.1 is adjusted to pressurize the...

Embodiment 4

[0082] A test method for an outrigger hydraulic cylinder imitation working condition test bench, on the basis of the above-mentioned first embodiment,

[0083] Start pressure characteristic test:

[0084] 1. The tested cylinder 16 is placed flat on the starting pressure test bench without any load;

[0085] 2. Adjust the pressure value of loading pump 19 and relief valve II 10.2 to 0MPa;

[0086] 3. The auxiliary motor 20 is powered on to start, the relief valve II 10.2 is powered on, the YA2.8 terminal of the three-position four-way reversing valve III 12.3 is powered on, and the pressure of the loading pump 19 and the relief valve II 10.2 is gradually adjusted. value, so that the system pressure gradually increases from 0MPa until the cylinder under test starts;

[0087] Test parameters: pressure of pressure sensor VII 15.7 (pressure of rodless cavity of tested cylinder 16), test time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com