Electric motor for water pump

A technology of electric motors and water pumps, applied in the field of electric motors, can solve the problems of the normal operation of the fuselage, affect the ecological environment, and poor heat dissipation performance of the fuselage, and achieve good heat dissipation effect, isolation of pollution problems, effective and timely heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

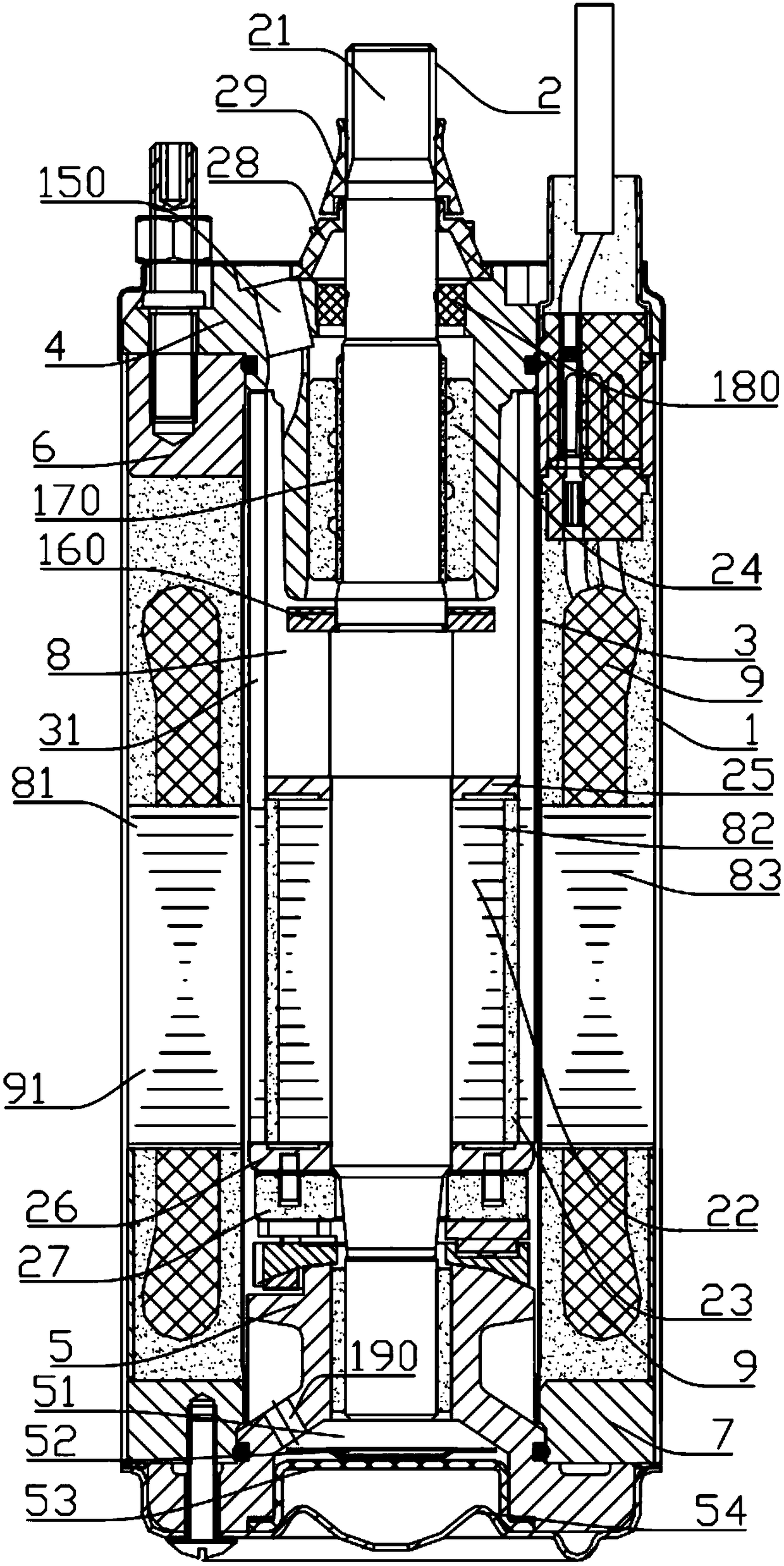

[0020] Example 1: as figure 1 As shown, a motor for a water pump includes a casing 1, a rotor assembly 2, a shielding sleeve 3, an upper bearing seat 4, a lower bearing seat 5, an upper end cover 6 and a lower end cover 7; The rotor shaft 21, the rotor 22 sleeved on the rotor shaft 21 and the magnetic steel sleeve 23 in the casing 1; the upper bearing seat 4 is arranged on the upper end of the upper end cover 6, and the lower bearing seat 5 is arranged on the lower end cover 7, and a cavity 8 is formed between the casing 1, the upper end cover 6 and the lower end cover 7, the cavity 8 includes a stator cavity 81 and a rotor cavity 82; the shielding sleeve 3 is sleeved on the rotor Inside the cavity 82, the shielding sleeve 3 is sleeved on the outside of the rotor assembly 2; the shielding sleeve 3 is formed with an accommodating cavity 31 filled with clean water and used for heat dissipation.

[0021] The motor of this technical solution is a shielded motor. The stator adopts...

Embodiment 2

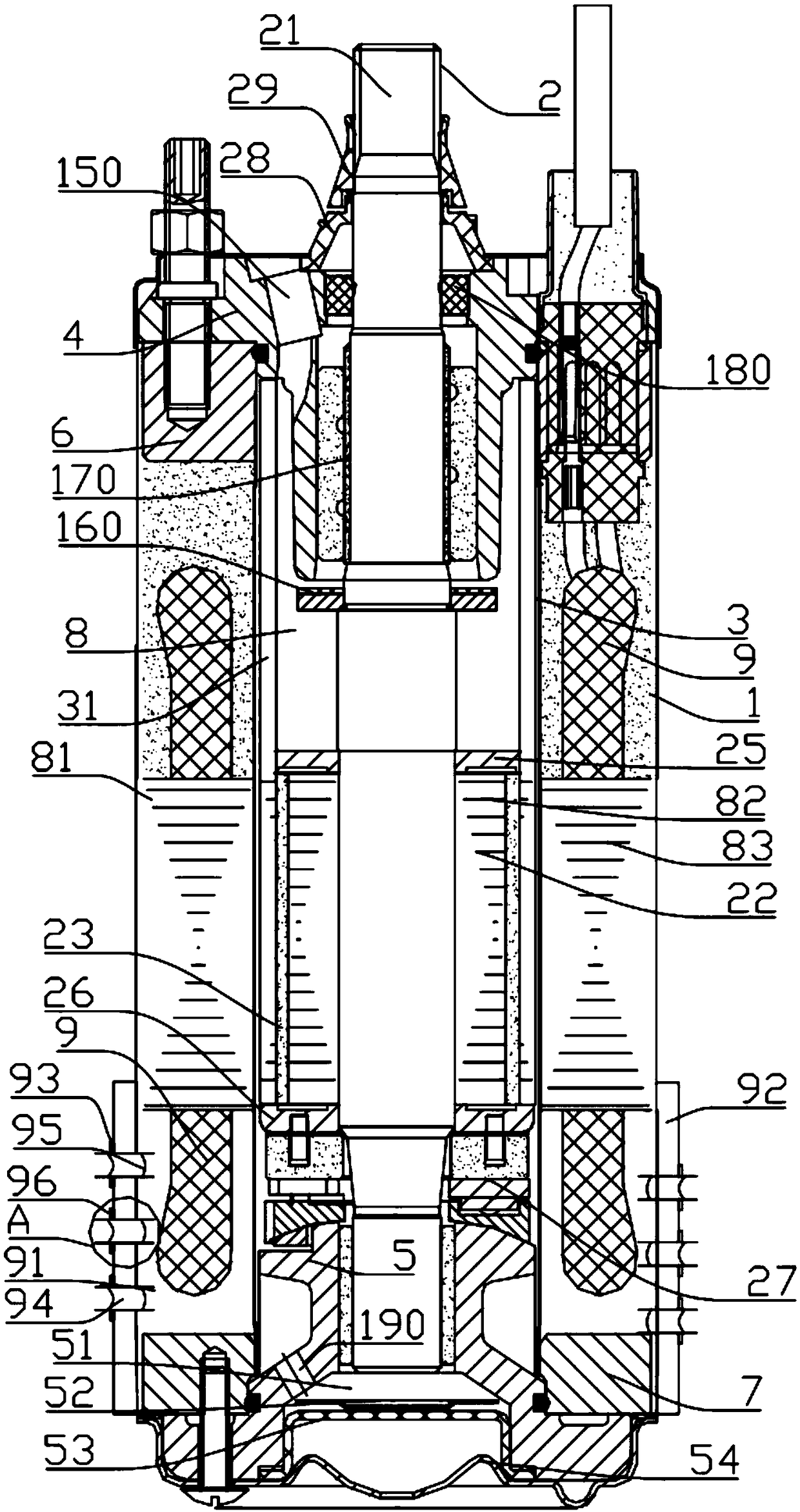

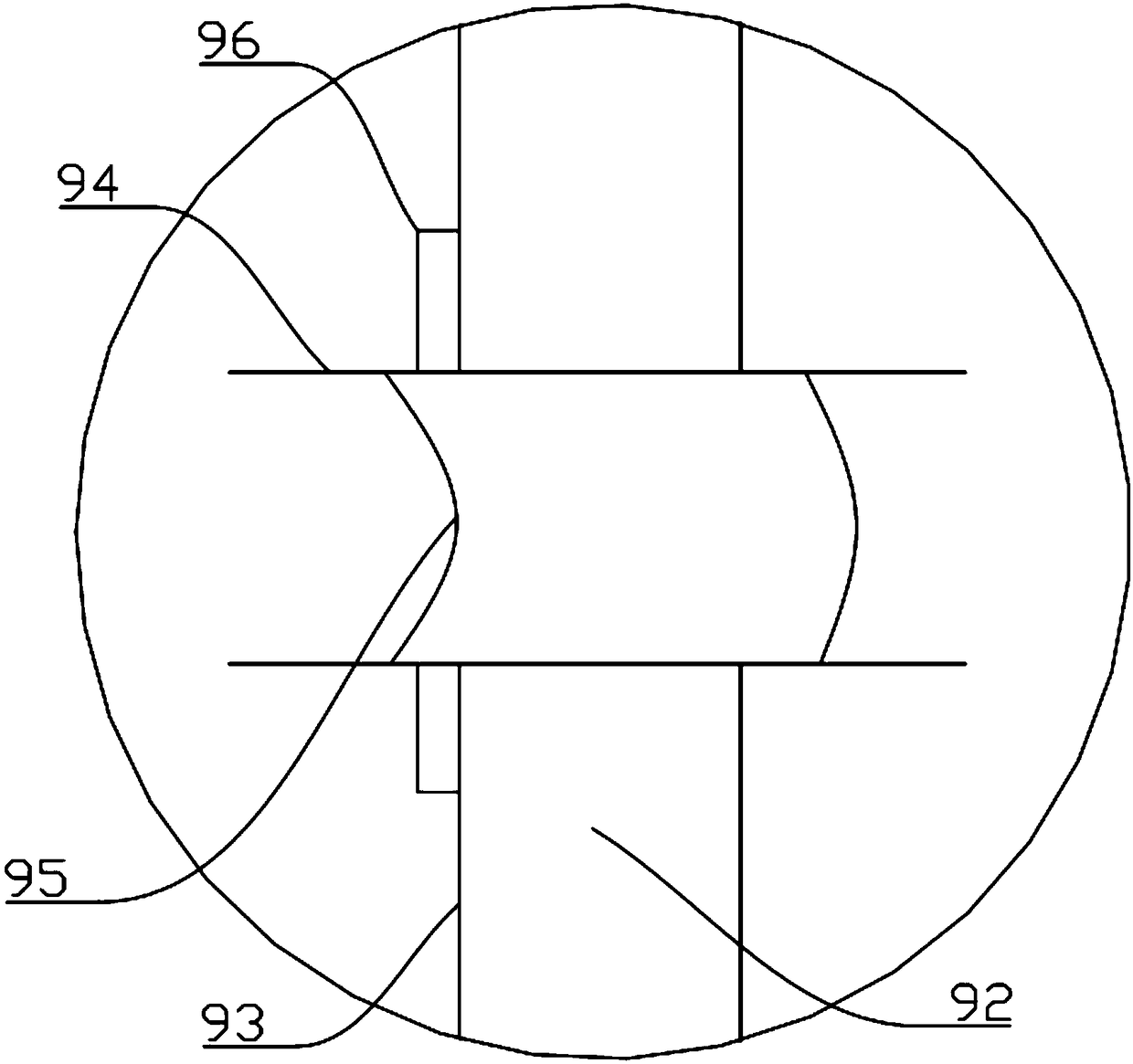

[0038] Embodiment 2: as Figure 2-3 As shown, this embodiment is basically the same as the first embodiment, the difference is that a cavity 92 is formed in the side wall 93 of the sealing cavity 91, and a plurality of water pipes penetrating the cavity 92 are arranged on the side wall 93 94. One end of the water passage pipe 94 is located outside the side wall 93, and the other end is located in the sealed cavity 91. At least one sand-proof filter layer 95 is arranged in the water passage pipe 94.

[0039] The arrangement of the water pipe 94 in this technical solution makes the inside of the motor have good ventilation performance, and the heat generated by the motor during operation can be effectively discharged, which solves the problem that the internal heat of the motor cannot be discharged, and the normal operation of the motor is seriously affected by the high internal temperature. In addition, the sand-proof filter layer 95 in the water pipe 94 can prevent the sand an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com