Drive mechanism for a comfort drive of a motor vehicle and a comfort drive

A technology of driving mechanism and driving device, which is applied in the direction of transmission device, electromechanical device, special position of vehicle, etc., can solve problems such as noise and unpopularity, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

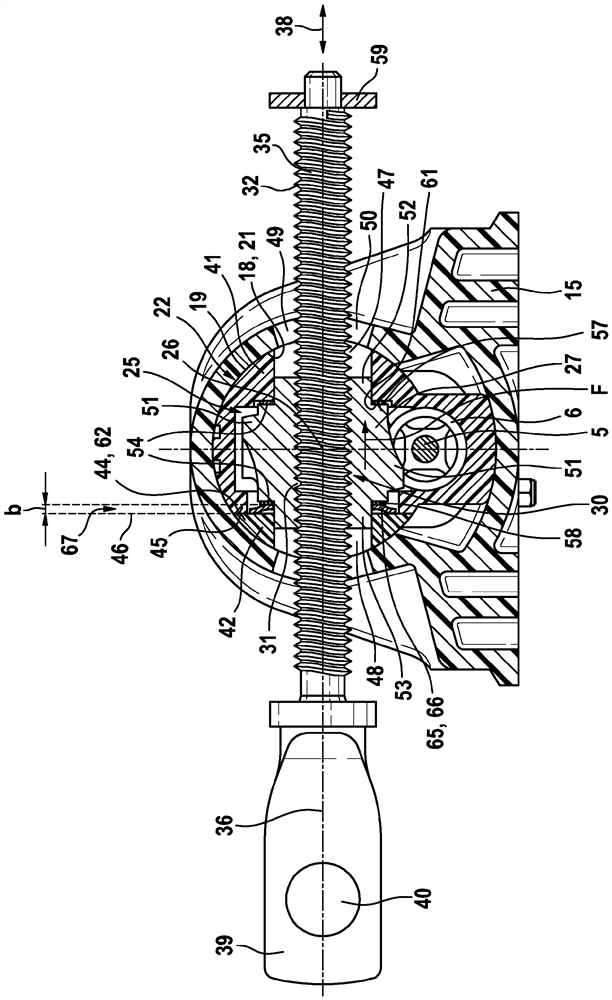

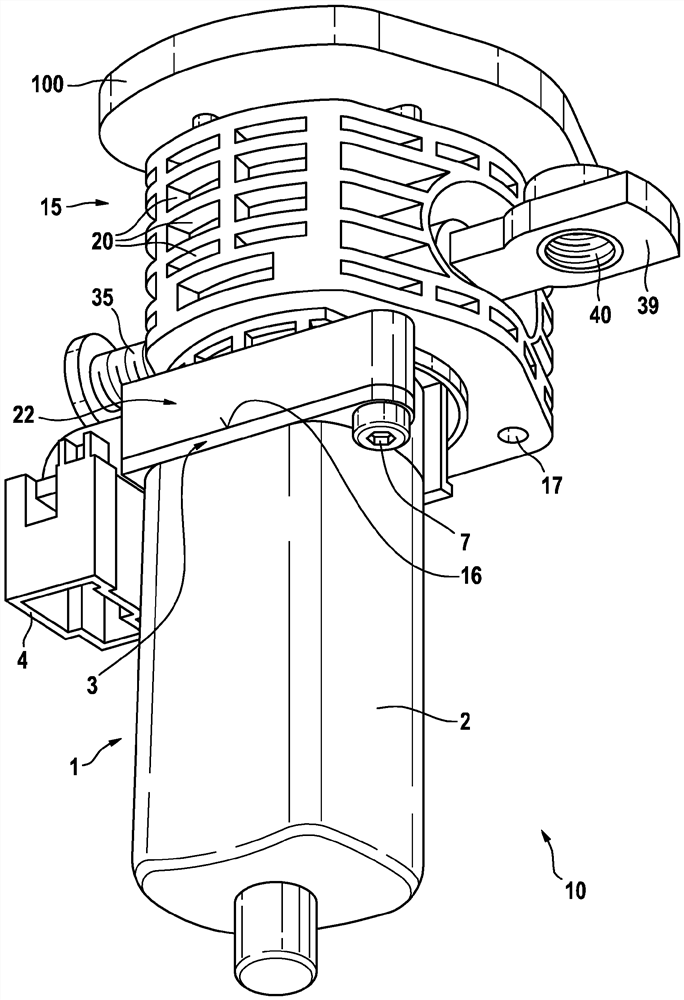

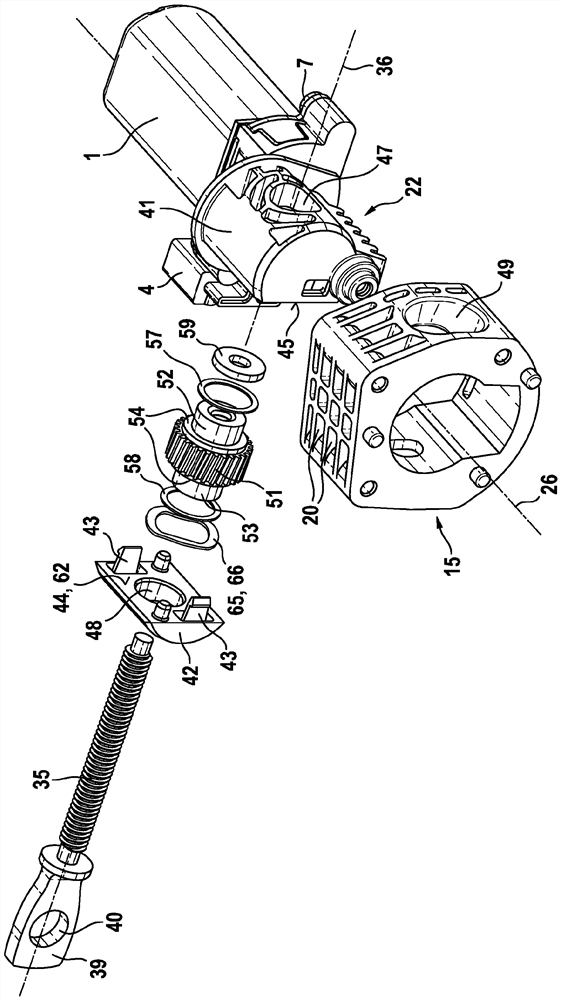

[0019] exist figure 1 A drive mechanism 10 for a comfort drive of a motor vehicle is shown. Such a comfort drive can be designed, for example, in the form of a seat adjustment drive or a steering column adjustment drive. However, the present invention should not be limited to such an application of the drive mechanism 10 .

[0020] The drive mechanism 10 comprises an electric motor 1 with a housing, for example made of metal, produced by deep-drawing in the form of a pole pot housing 2, and a connecting flange 3, which is connected. The flange has a connector body 4 for making electrical contact with the electric motor 1 . The drive shaft 5 of the electric motor protrudes from the pole pot housing 2 or the connecting flange 3 of the electric motor 1 ( figure 2 ). The drive shaft 5 has a worm gear 6 in the region protruding from the pole pot housing 2 or the connecting flange 3 .

[0021] The pole pot housing 2 of the electric motor 1 or its connecting flange 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com