Production equipment and production method of edible tableware

A technology of production equipment and production method, which is applied in the field of production equipment of edible tableware, can solve the problems of low production efficiency of edible tableware, low creation value, and high water content of dough, so as to achieve high output value, increase production rate, and speed up production. The effect of demoulding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

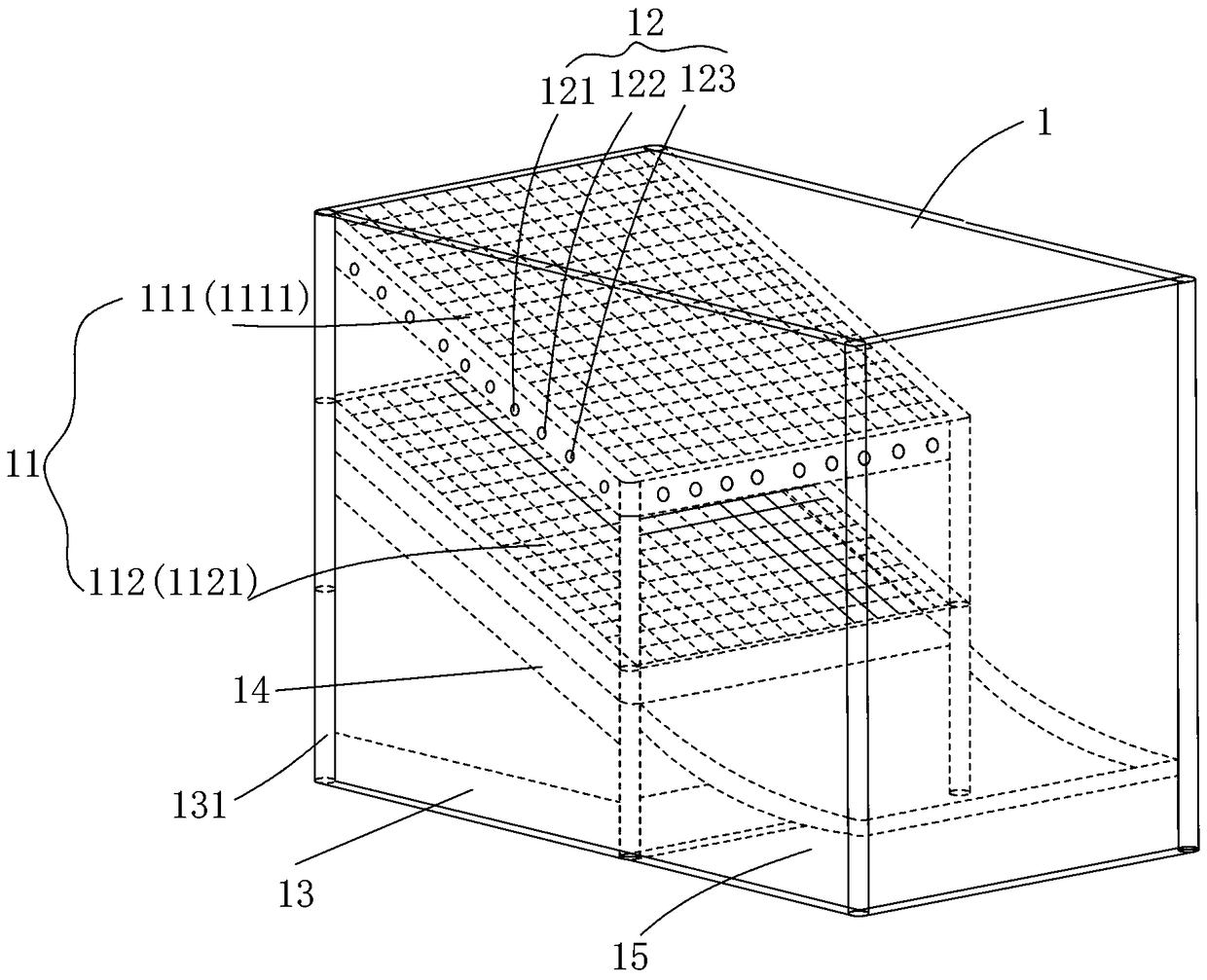

[0032] Such as figure 1 As shown, the present invention provides a kind of production equipment of edible tableware, comprises sealing cavity 1, and sealing cavity 1 is provided with molding mold 11 and feeding device 12; The raw material that edible tableware is made; Profile mold 11 is as the mold that edible tableware is made. The sealed cavity 1 can reduce the consumption of raw material dust and the pollution to the workshop, and is also conducive to the settlement of mist and dust to accelerate the pressing. The sealed cavity 1 is surrounded by a transparent sealing plate.

[0033] Specifically, the molding die 11 includes an upper mold 111 and a lower mold 112, the lower mold 112 is fixed in the sealed cavity 1 through a bracket, and the lower mold 112 is assembled from several lower mold pieces 1121; each lower mold piece 1121 is a convex Die, the peripheral edge of the punch is spliced with the adjacent punch to form a pair of huge lower die, the splicing between ...

Embodiment 2

[0038] Embodiment 2: the making of spinach taste edible bowl

[0039] (1) Mix wheat and dehydrated spinach at a weight ratio of 10:1 and crush them into 300-mesh ultrafine powder in an environment of -20°C, and then transport the ultrafine powder to the whole grain powder supply device;

[0040] (2) The control device activates the hydraulic press 13 to raise the upper die 111 in the equipment to the top of the sealed cavity 1; the molding die 11 can press 500 bowls at a time, and the 500 bowls are densely arranged on the die in a 7*7 manner into a square;

[0041] (3) The control device opens the first spray head 121 (the spray hole diameter of the spray head is 200 mesh) to spray the ultra-fine powder in the sealed cavity 1 in mist form to form a dispersed ultra-fine powder mist; the first spray head 121 is connected to a A high-pressure spray gun, the above-mentioned 300 mesh ultrafine powder is housed in the high-pressure spray gun, the high-pressure spray gun is started,...

Embodiment 3

[0047] Embodiment 3: the making of honey taste edible bowl

[0048] (1) Mix wheat, corn and honey at a weight ratio of 10:1, and then crush them into 500-mesh superfine powder in an environment of -60°C, and then transport the superfine powder to the whole grain powder supply device;

[0049] (2) The control device activates the hydraulic press 13 to raise the upper die 111 in the equipment to the top of the sealed cavity 1; the molding die 11 can press 500 bowls at a time, and the 500 bowls are densely arranged on the die in a 7*7 manner into a square;

[0050] (3) The control device opens the first nozzle 121 (the nozzle hole diameter is 400 mesh) to spray the ultrafine powder into the sealed cavity 1 in mist form to form a dispersed ultrafine powder mist; the first nozzle 121 is connected to a A high-pressure spray gun, the above-mentioned 500 mesh ultrafine powder is housed in the high-pressure spray gun, the high-pressure spray gun is started, and the ultrafine powder is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap