Reciprocatory dry shaver

A technology of reciprocating motion and motion device, which is applied in the direction of AC motor control, metal processing, electrical components, etc., and can solve problems such as vibration frequency change, speed slowdown, unbalanced vibration of the shaver head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

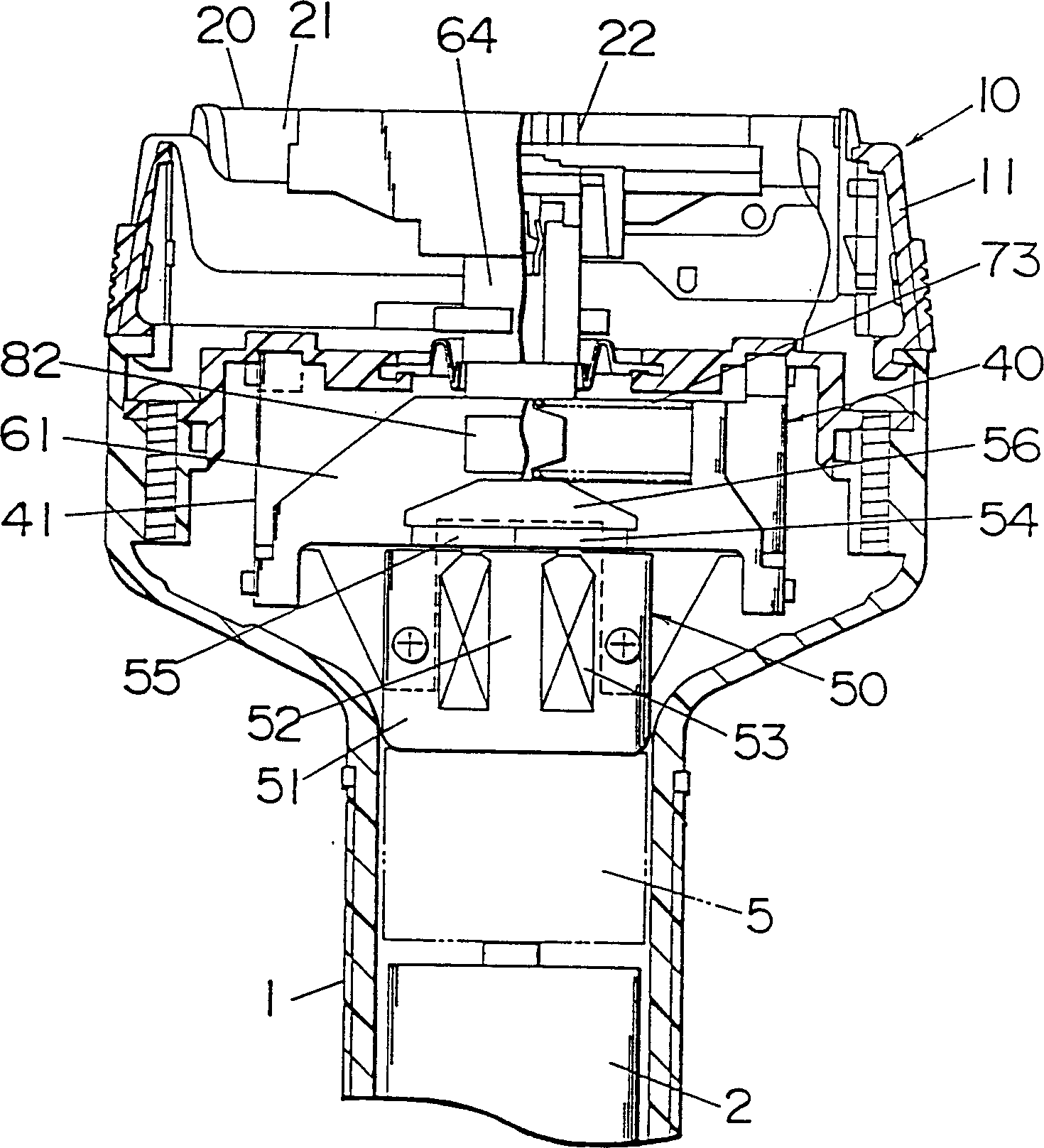

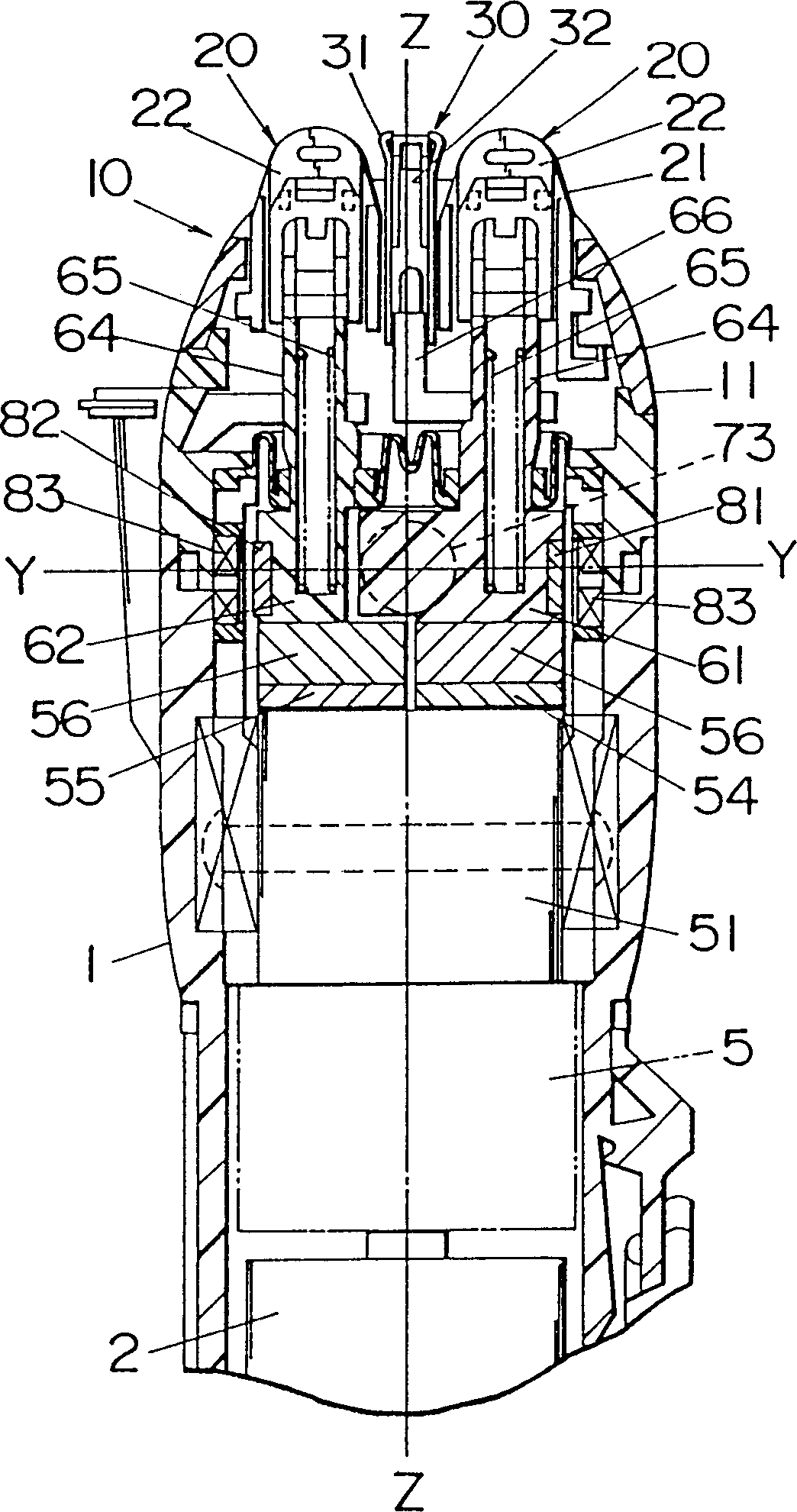

[0029] Example 1 ( Figure 1-12 )

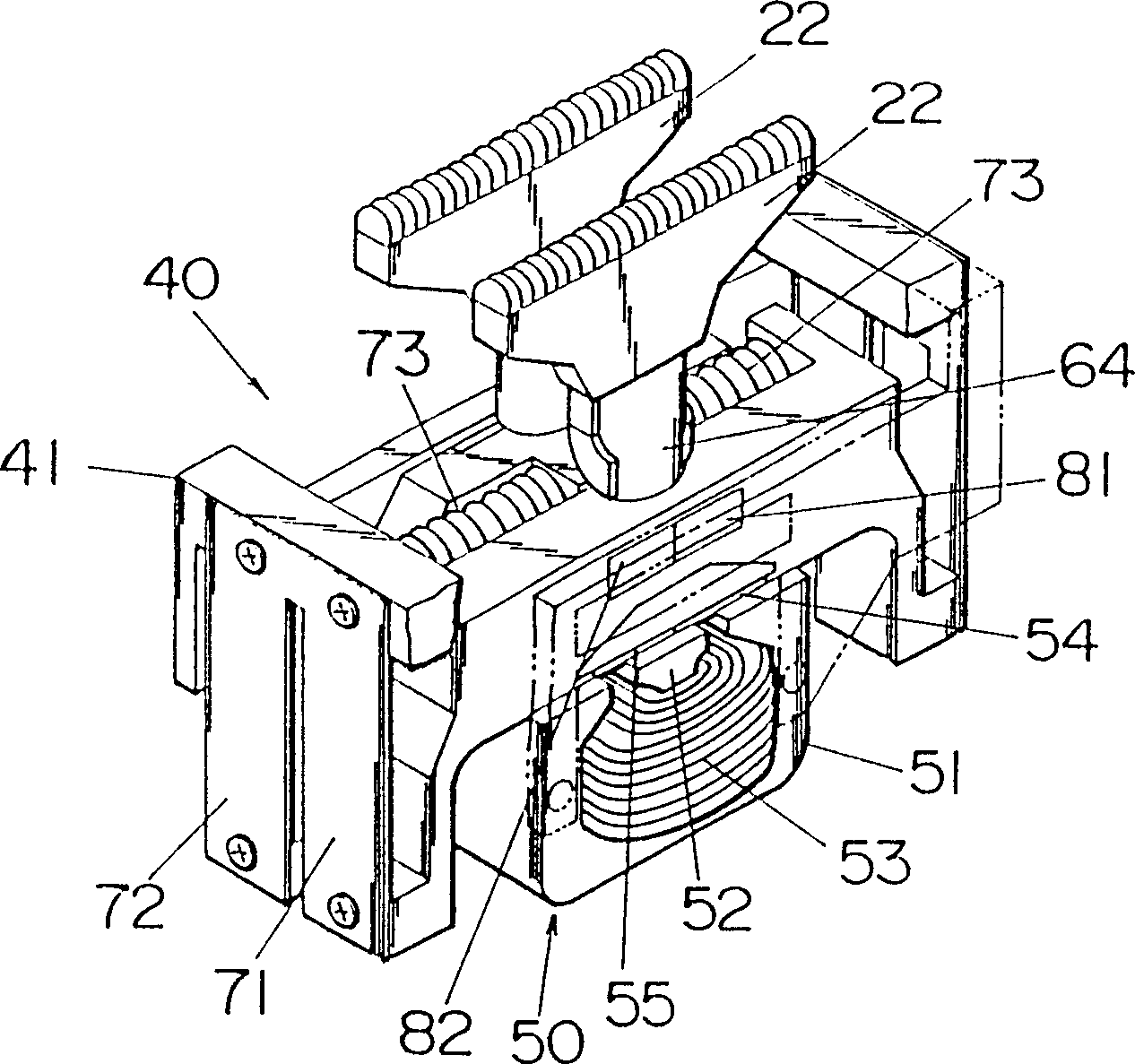

[0030] refer to Figure 1-Figure 5 , which represents the reciprocating type dry shaver of the first embodiment of the present invention. This shaver comprises shell 1 with shaver head 10, is provided with two outer blade heads 20 and a middle blade head 30 on the shaver head, middle blade head 30 and outer blade head 20 extend horizontally parallel to each other . The outer blade head 20 includes a stationary blade 21 whose cutting piece is generally U-shaped in cross-section and a moving blade 22 that is driven to reciprocate and contacts the stationary blade 21 during cutting. The stationary blade 21 is installed on the head frame 11, and the head frame is detachably mounted on the shell 1, and the movable blade 22 is mounted on the blade holder 40 in the shell 1 at the same time. The middle blade head 30 includes a generally U-shaped serrated blade 31 and a movable blade 32 driven to reciprocate and contact the blade 31 during cuttin...

Embodiment 2

[0051] Example 2 ( Figure 13-16 )

[0052] Figure 13-16 Showing the dry shaver according to the second embodiment of the present invention, the structure is the same as that of the first embodiment except that reciprocators 61A and 62A of different shapes are used. The same components as above are denoted by the same reference numerals with a subscript "A" and their description will not be repeated here. The reciprocator 62A in the form of a rectangular frame comprises two parallel elements 162 connected by end bars 161 , while the reciprocator 61A comprises an elongated element disposed between the elements 162 . Extending from a member 162 of the reciprocator 62A is an engagement portion 64A for mounting the movable blade 22A corresponding to the outer blade head 20A. The other reciprocator 61A has an engaging portion 64A protruding from an intermediate protrusion 68A for coupling with the movable blade 22A holding the blade head 20A. A part 66A coupled with the moving...

Embodiment 3

[0066] Embodiment 3 ( Figure 17 and 18 )

[0067] Figure 17 Shown is a blade holder 40B employed in the dry shaver according to the third embodiment of the present invention. The blade holder 40B is the same as the blade head 40 in the first embodiment except that one coil spring 73B is shared among the two vibration systems of the reciprocators 61B and 62B. Like parts are denoted by like reference numerals with a subscript "B". In this example, as Figure 18 As shown, inwardly protruding end projections 67B are formed on the reciprocators 61B and 62B, respectively, and a coil spring 73B is provided between the projections 67B. The coil spring 73B has a spring constant which, when added to the horizontal components of the leaf springs 71B, 72B and the motor, provides force constants K1 and K2 suitable for both vibration systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com