A high-speed wheel tread structure suitable for wide rails in alpine regions

A technology for wheel treads and alpine regions, applied in the direction of rim measurement/measurement, etc., to achieve the effects of suppressing meandering motion, prolonging the repair cycle, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

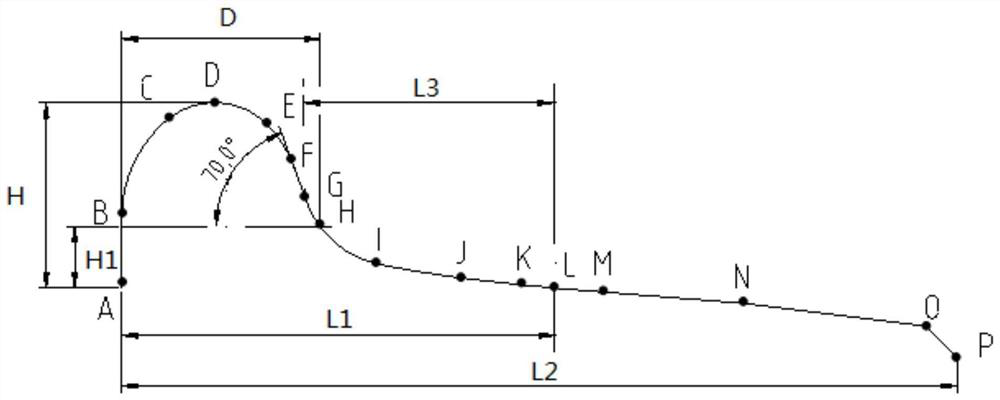

[0017] refer to figure 1 The specific embodiment of the present invention includes the rim area, the tread area, and the transition area between the rim and the tread, and the rim part is connected smoothly by three sections of arcs BC, CE, EF and two straight lines AB, FG , the radius of the first arc BC is 19-21mm, the radius of the second arc CE is 11-13mm, the radius of the third arc EF is 19-21mm, and the angle between the extension line of the straight line FG and the horizontal line is 70°

[0018] The tread area is connected tangentially and smoothly by two sections of arcs JK, KM and two sections of oblique lines MN, NO in sequence, the OP section at the outer end is chamfered at 45°, and the radius of the first section of arc JK is 345-355mm , the radius of the second arc KM is 490-510mm, the slope of the first oblique line MN is 1 / 13-1 / 11, and the slope of the second oblique line NO is 1 / 9-1 / 7. Point L is the highest point of the rolling circle, and points A and L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com