Chain feeding device

A chain and sprocket technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of deviation from the actual needs of the automatic feeding device in the factory, the structure of the feeding device is complicated, and the economic cost is high, so as to facilitate widespread promotion The effect of using, fewer transmission stages, and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

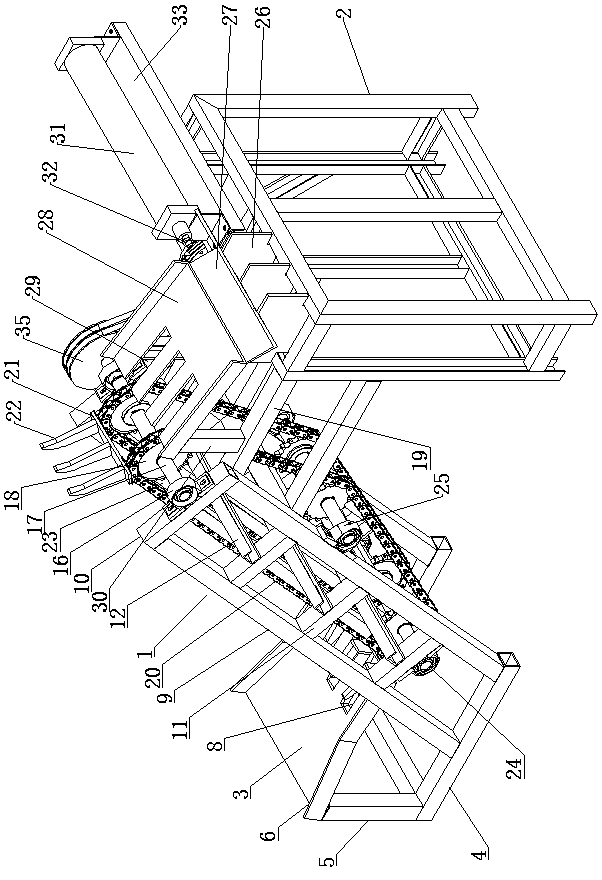

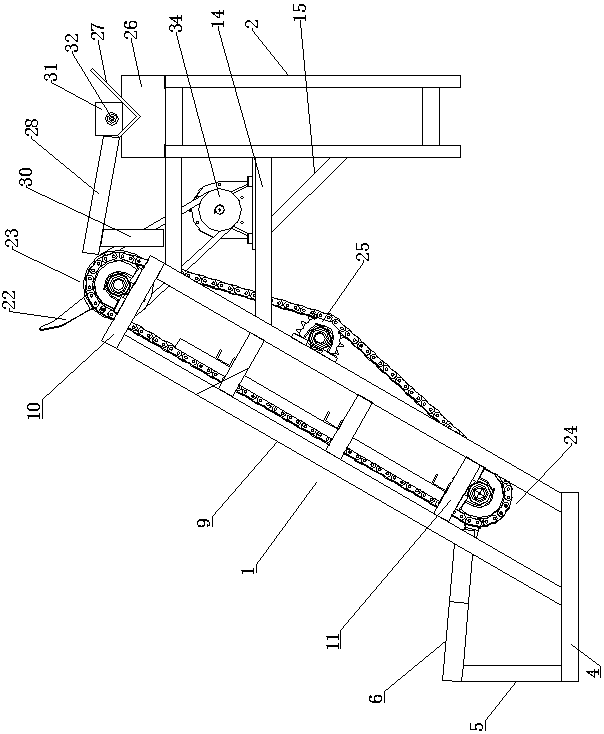

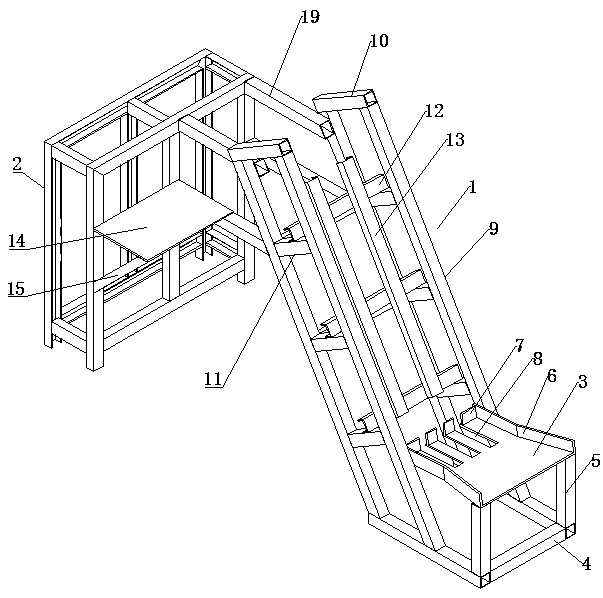

[0021] Such as Figure 1-3 As shown, a chain feeding device includes a feeding rack 1, and the feeding rack 1 includes two groups of rack bodies, left and right, and each group of rack bodies includes two inclined brackets 9 respectively, and the included angle between the inclined brackets 9 and the horizontal plane is 60°, the upper ends of the two inclined brackets 9 are connected with a first connecting rod 10, and the included angle between the first connecting rod 10 and the horizontal plane is 30°. Some reinforcing connecting rods 11 are connected between the two inclined brackets 9 below the first connecting rod 10, and some reinforcing connecting rods 11 are all parallel to the first connecting rod 10, and the lower end of the feeding frame 1 is connected with the base frame 4, and the base frame 4. It is arranged horizontally. There are some reinforced cross bars 12 connected between the left and right two groups of frames. Several reinforced cross bars 12 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com