Precise composite measuring tool, sand core positioning method and aero-engine aluminum-magnesium alloy casting

A positioning method and sand core technology, applied in the direction of casting molds, cores, measuring devices, etc., can solve the problem that the dimensional control method cannot meet the dimensional accuracy of castings, so as to improve dimensional accuracy and casting quality, ensure accuracy, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

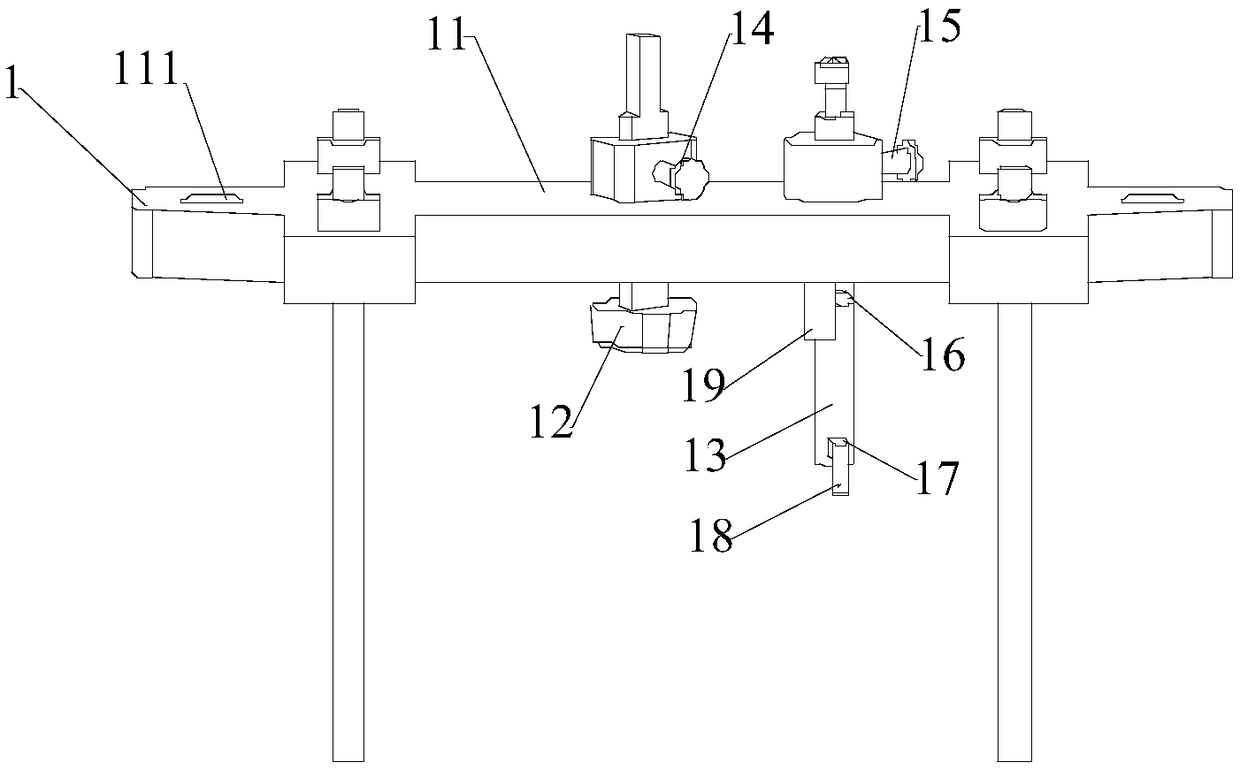

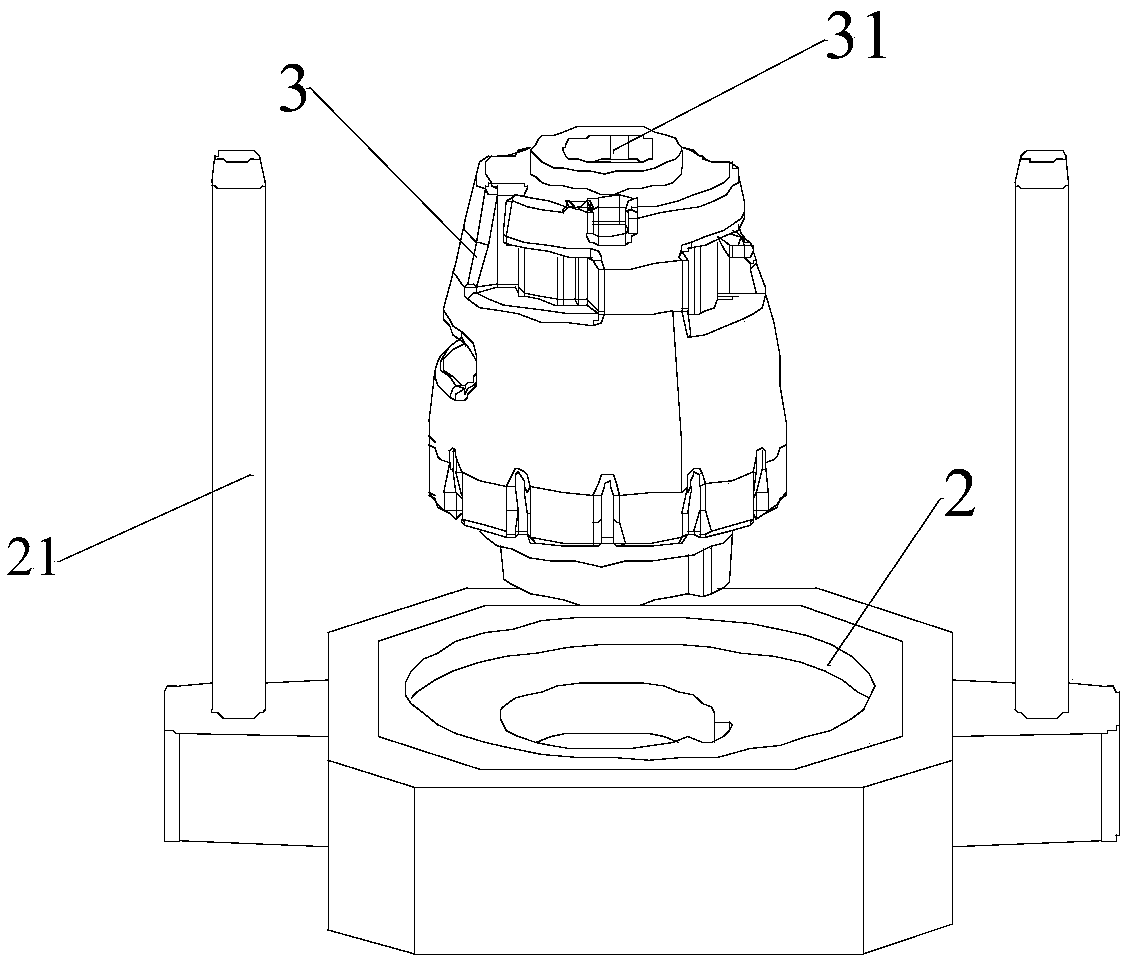

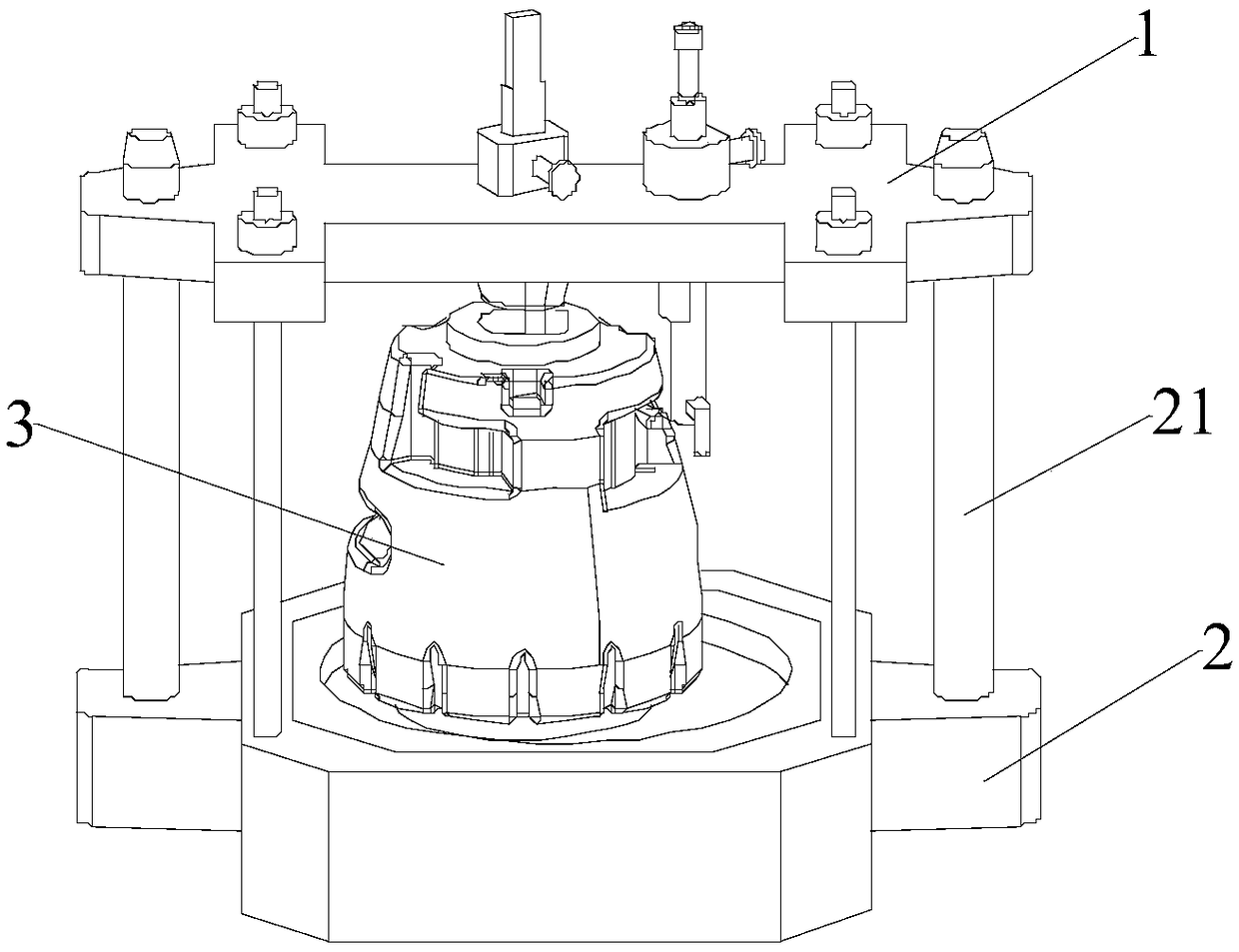

[0039] Specific embodiments: S1: Coat the contact part of the sand core 3 and the casting box 2 with an adhesive, assemble the sand core 3 on the casting box 2, and perform initial positioning; S2: Pass the precision composite measuring tool 1 through the positioning pin 21 to Disassemble the connection in the positioning hole 111 of the mounting plate 11; S3: adjust the measuring rod 12 on the mounting plate 11 through the first control part 14 to adjust the distance that the measuring rod 12 falls into the center hole 31, reach the bottom of the sand core 3, and measure the sand The central position and angular position of the core 3, the sand core 3 can reach the bottom, indicating that the central position and angular position of the sand core 3 meet the requirements. The height is measured by setting up a height observation platform, and the short step surface is not higher than the plane of the positioning seat , when the high step surface is not lower than the plane of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com