Ultrasonic gas meter

A gas meter and ultrasonic technology, applied in measuring devices, instruments, measuring flow/mass flow, etc., can solve problems such as stagnant water, inability to use gas for gas equipment, and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

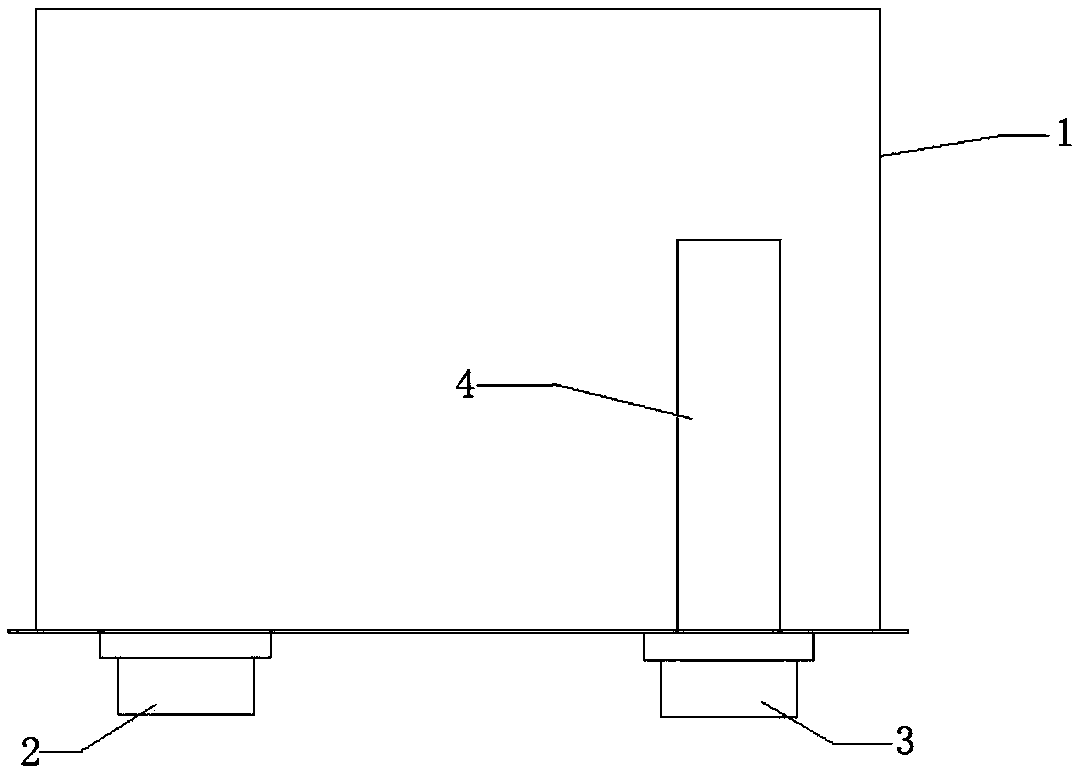

[0027] Such as Figure 1-2 Shown is a schematic structural diagram of an embodiment of an ultrasonic gas meter, which includes a housing 1 , an air inlet 2 , an air outlet 3 , and a metering module 4 . The air inlet 2 and the air outlet 3 are respectively connected to existing gas pipelines.

[0028] The air inlet 2 and the air outlet 3 are respectively provided at the bottom of the casing 1 . The air inlet 2 is arranged at the bottom of the housing 1, so that the path of gas intake in the pipeline enters the interior of the housing 1 from bottom to top, and the water in the pipeline cannot enter through the air inlet 2 under the action of gravity. The gas outlet 3 is provided at the bottom of the housing 1, so that the gas in the pipeline is discharged from the housing 1 from top to bottom, and the accumulated water in the housing 1 is discharged from the gas outlet 3 under the action of gravity.

[0029] The setting positions of the air inlet 2 and the air outlet 3 in this...

Embodiment 2

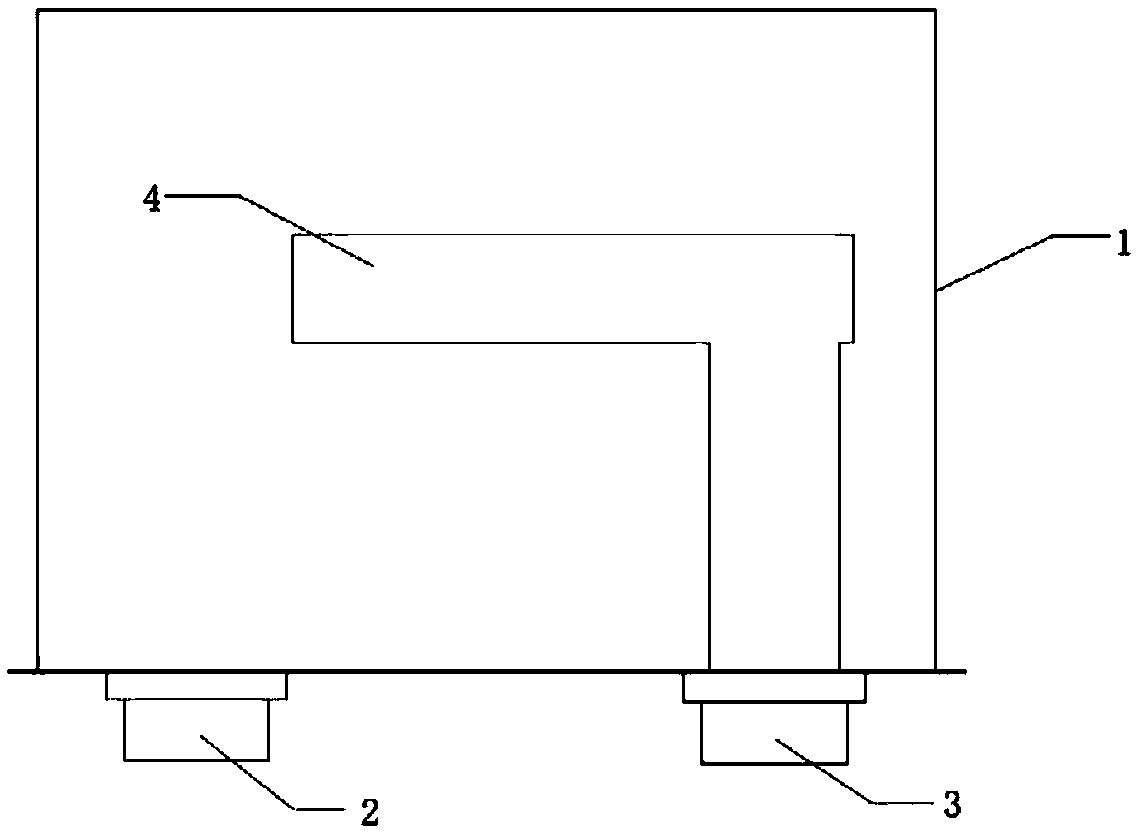

[0036] Such as Figure 3-4 As shown: the structure of an ultrasonic gas meter includes a housing 1, a metering module 4, the metering module 4 is set in the housing 1, the housing 1 is provided with an air inlet 2 and an air outlet 3, and the air inlet 2 and the outlet Gas ports 3 are respectively connected to existing gas pipelines.

[0037]The air inlet 2 is arranged on the bottom surface of the casing 1, and the air outlet 3 is arranged on the side surface of the casing. The air inlet 2 is arranged at the bottom of the casing, so that the path of gas intake in the pipeline enters the inside of the casing from bottom to top, and the water in the pipeline cannot enter through the air inlet 2 under the action of gravity. The air outlet 3 is provided on the side of the housing, so that the path of the gas in the pipeline from the housing is horizontal, and the accumulated water in the housing is discharged from the air outlet 3 .

[0038] The setting positions of the air inle...

Embodiment 3

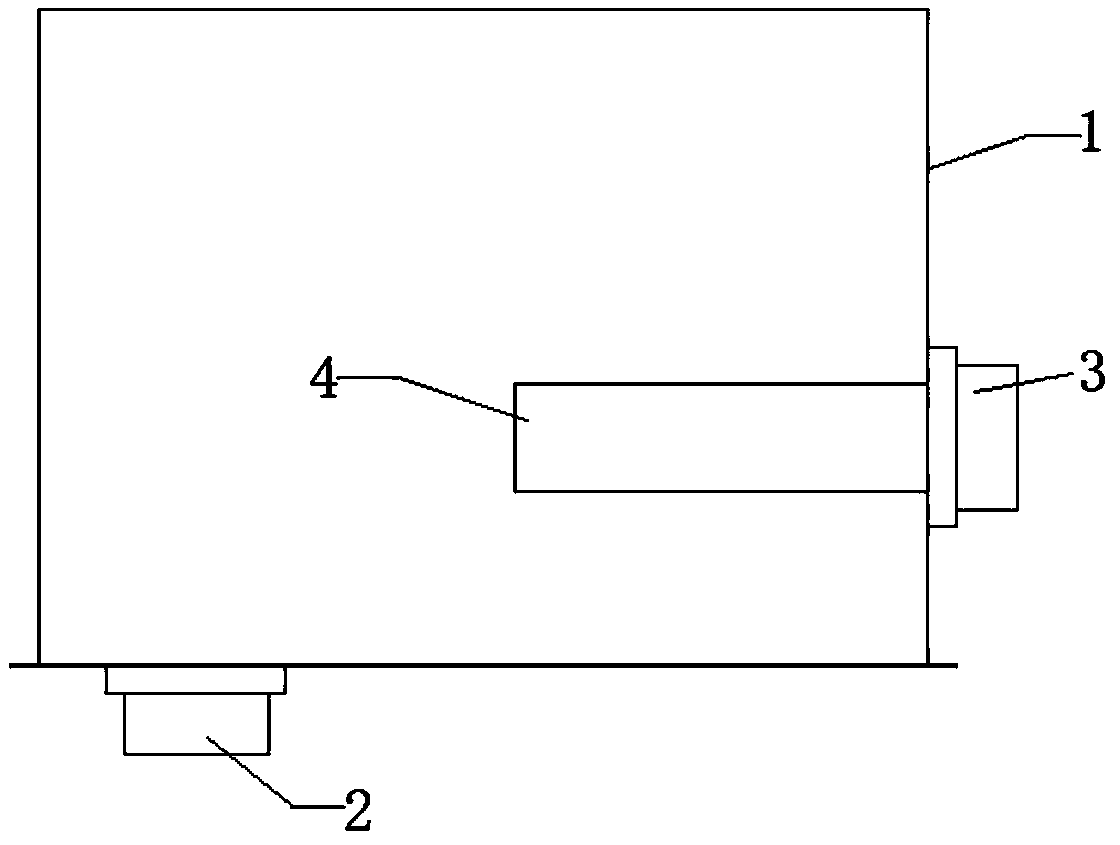

[0042] Such as Figure 5 As shown, an ultrasonic gas meter includes a housing 1 and a metering module 4, the metering module 4 is arranged in the housing 1, and the housing 1 is provided with an air inlet 2 and an air outlet 3, and an air inlet 2 and an air outlet 3 Connect the existing gas pipelines respectively. The air inlet 2 is arranged on the bottom surface of the casing 1, and the air outlet 3 is arranged on the top of the casing. The air inlet 2 is arranged at the bottom of the casing, so that the path of gas intake in the pipeline enters the inside of the casing from bottom to top, and the water in the pipeline cannot enter through the air inlet 2 under the action of gravity. The air outlet 3 is provided at the top of the housing.

[0043] The metering module 4 is composed of a transducer, and the transducer is composed of one or more sets of ultrasonic probes and air passages. After the gas enters the housing 1 from the air inlet 2, a stable pressure gas chamber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com