Switching structure with stress splitting groove for wheel disc test

A wheel and stress technology is applied in the field of transfer structures with stress separation grooves, which can solve the problems of low bolt hole life on the installation side and large stress at the opening position of the transfer structure, so as to reduce the bolt hole edge stress on the installation side. , improve the life, improve the effect of extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

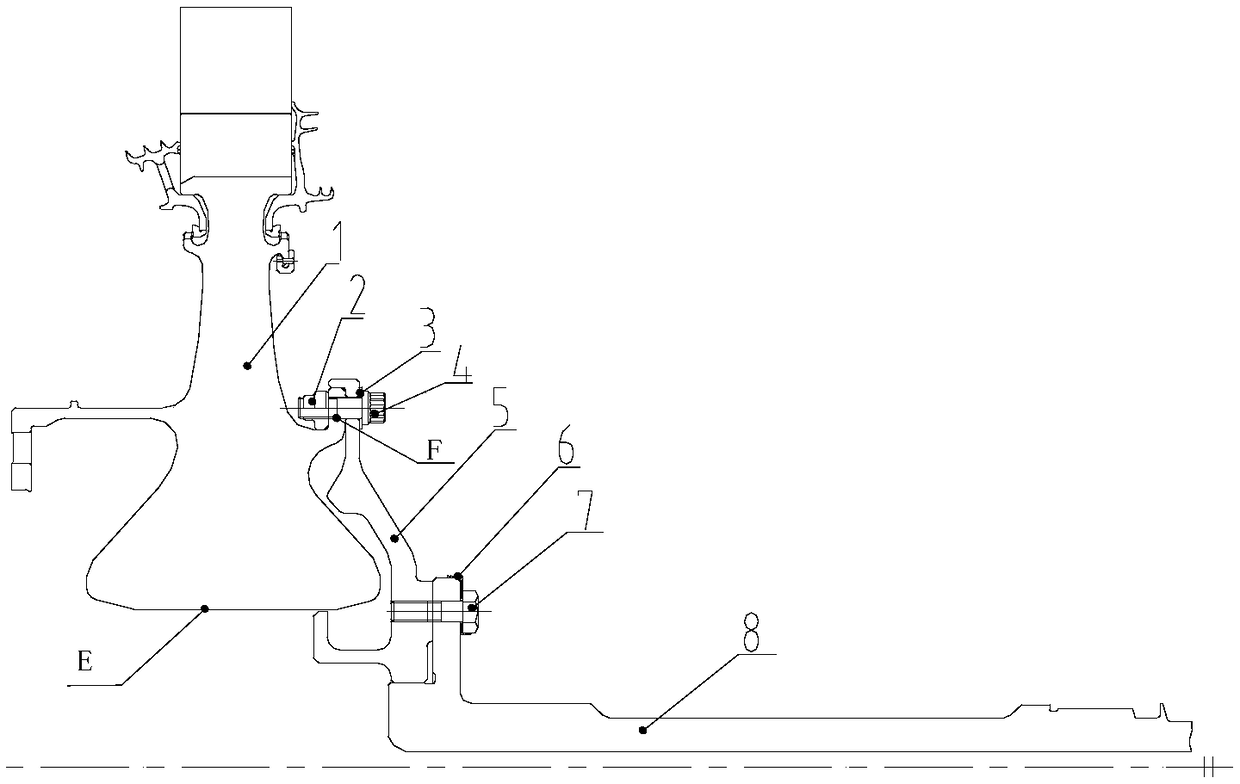

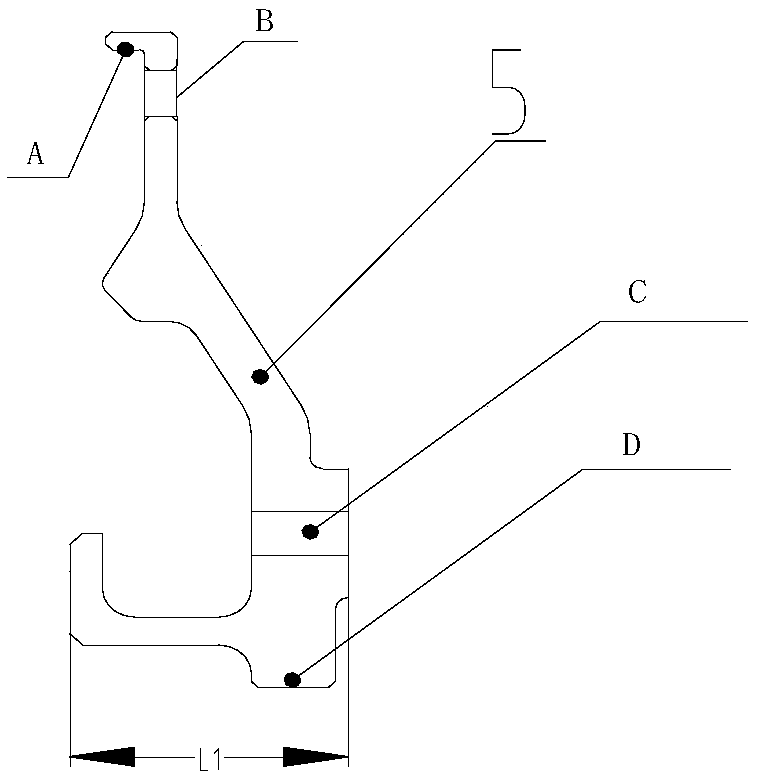

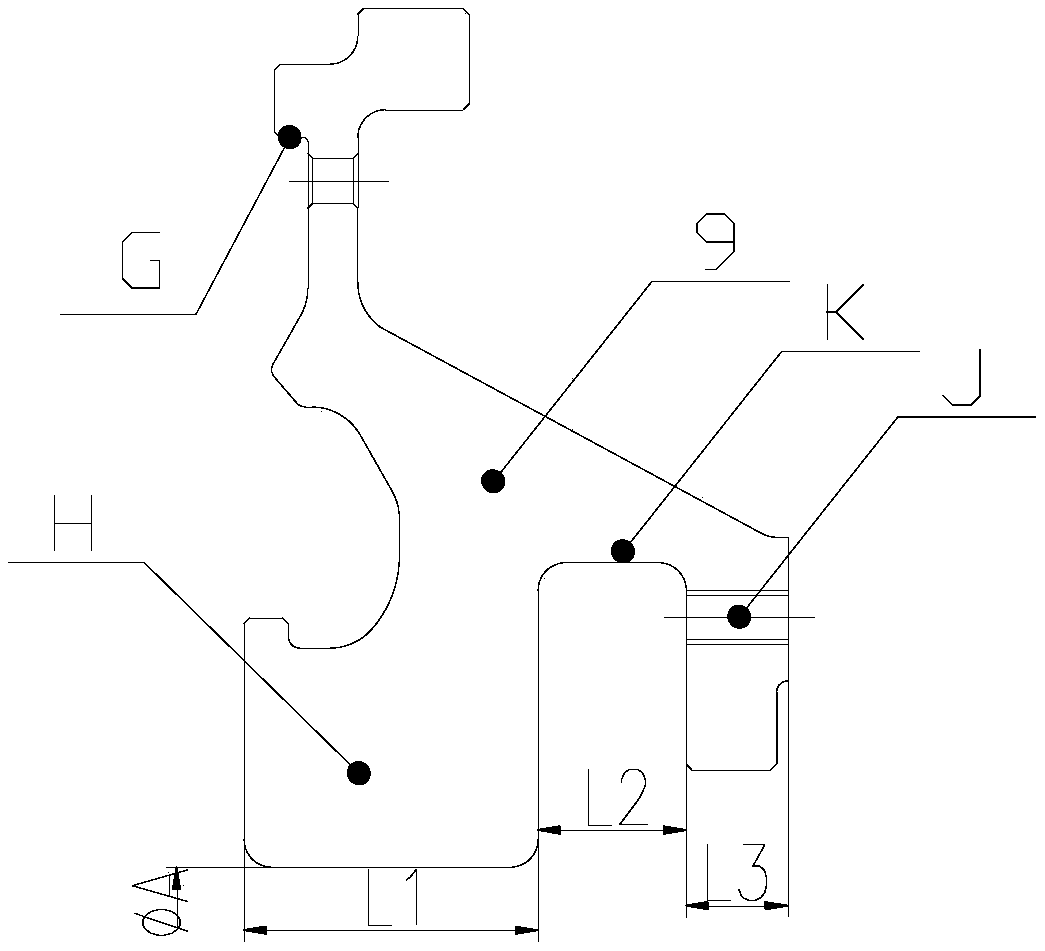

[0029] Such as image 3 As shown, the adapter structure 9 for the wheel disk test of this embodiment includes a hub part and a disc edge part, and the hub part includes a thickened part, a stress separation groove and a drive shaft connection part in the axial direction. When carrying out the low cycle fatigue test of the wheel disc, the wheel disc 1 is connected to the rim part, and the drive shaft connection part is connected to the drive shaft 8 .

[0030] By changing the axial dimensions L1, L2, and L3 of the thickened part, the stress separation groove, and the connecting portion of the drive shaft, the pressing force between the flange part of the adapter structure 9 and the wheel disc can be adjusted, and / or the drive shaft can be lowered. stress on the connection.

[0031] In other words, in the transfer structure 9 with stress separation grooves used in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com