Wall-attached stabilizing device for hydraulic engineering concrete tester

A water conservancy engineering and concrete technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as failure to filter concrete dust normally, surface damage of fair-faced concrete walls, and easy breakage of strike rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

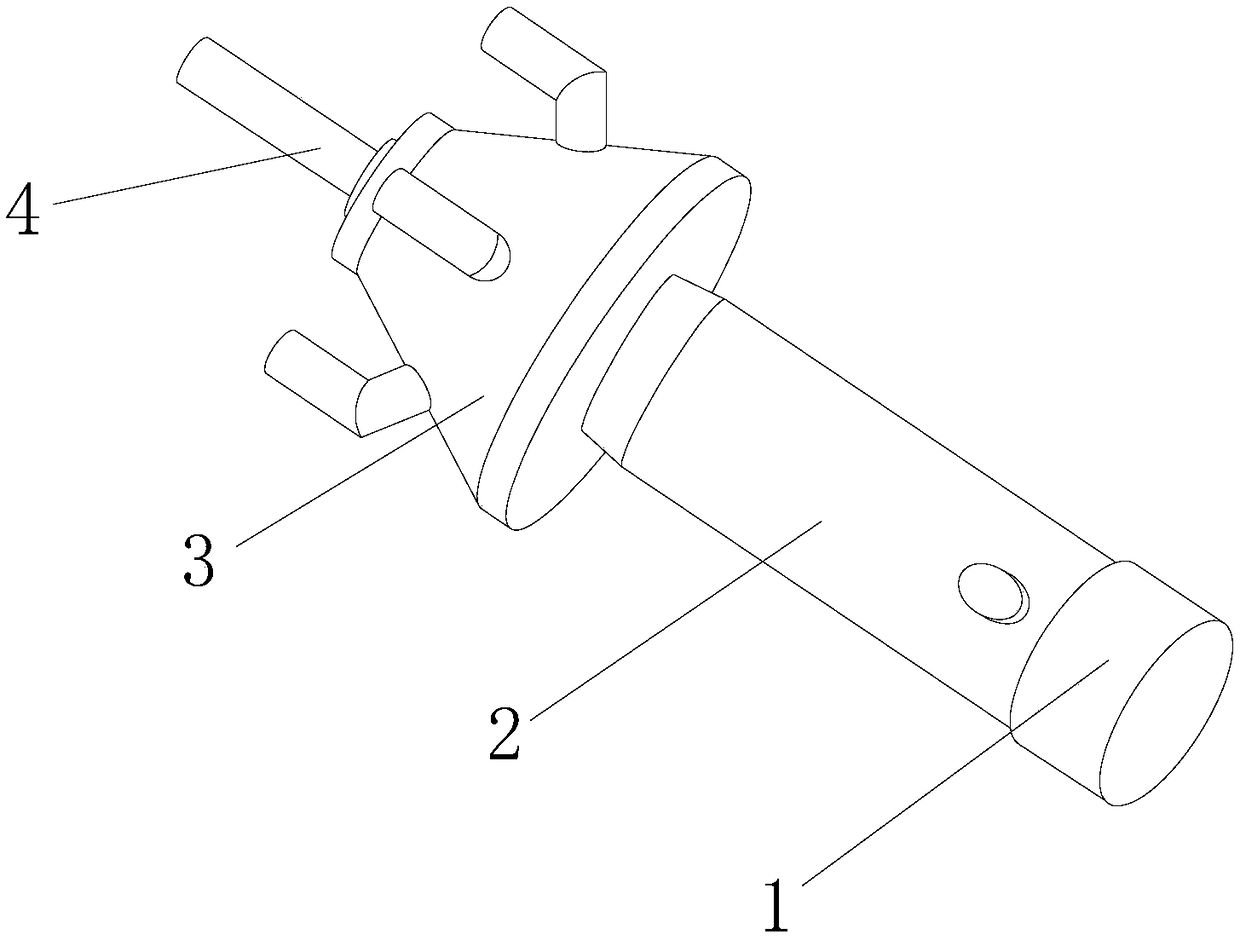

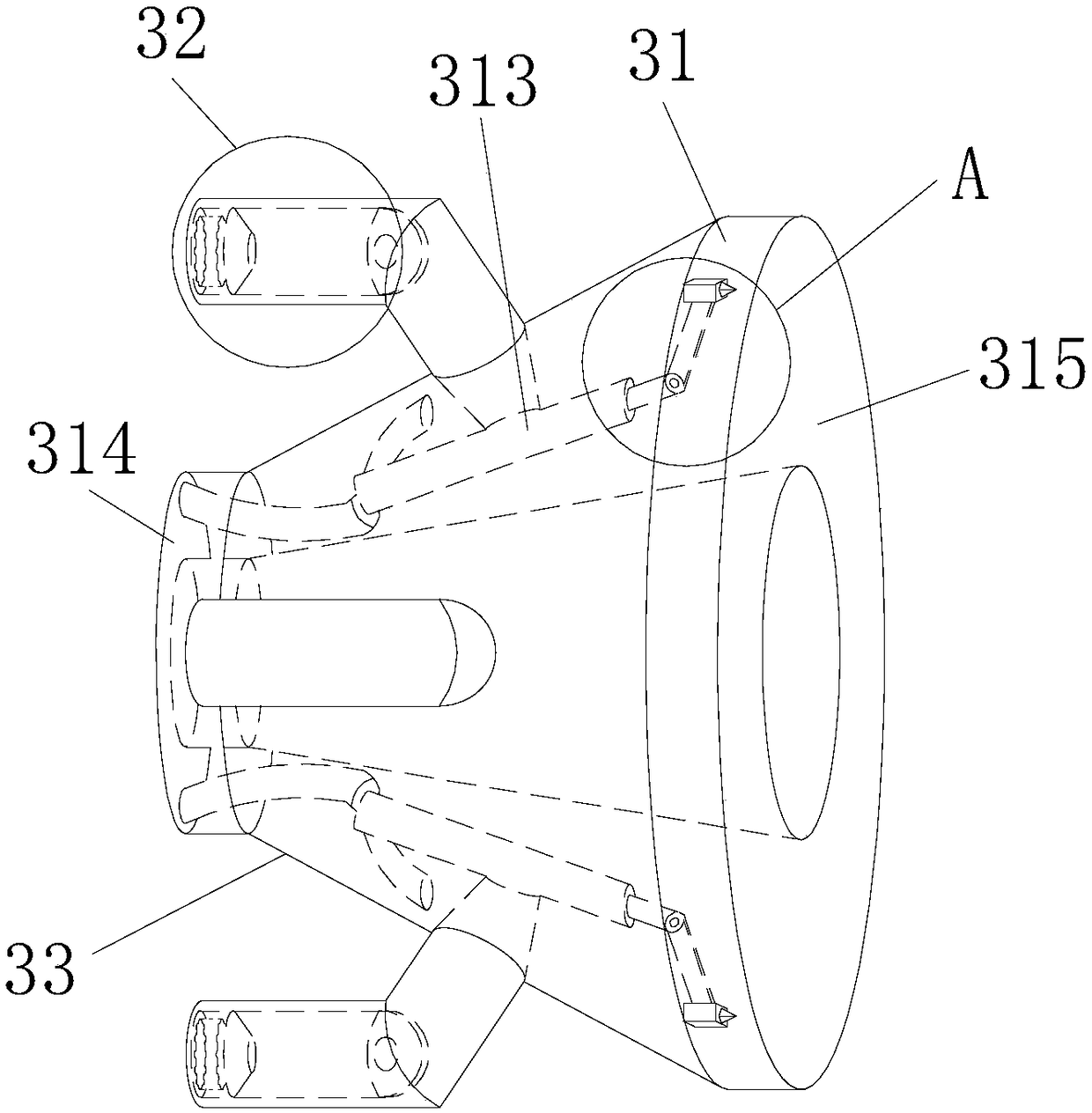

[0023] Such as Figure 1-Figure 6 As shown, the present invention provides a wall-mounted stabilizing device for a hydraulic engineering concrete detector, the structure of which includes a rear bracket 1, a body 2, a wall-mounted stabilizing device 3, and an ejection rod 4. The rear bracket 1 is wound around the body 2, the body 2 runs through the interior of the wall-attaching stabilization device 3, and the ejection rod 4 is embedded in the interior of the body 2, and the wall-attaching stabilization device 3 includes an expanding lock mechanism 31 and a flat suction mechanism 32 1. Outer shell 33, said lock expansion mechanism 31 and horizontal suction mechanism 32 mechanically cooperate through pipelines, said lock expansion mechanism 31 is horizontally installed inside the shell 33, and said flat suction mechanism 32 is installed on the outside of shell 33 through the outer pipe cover side.

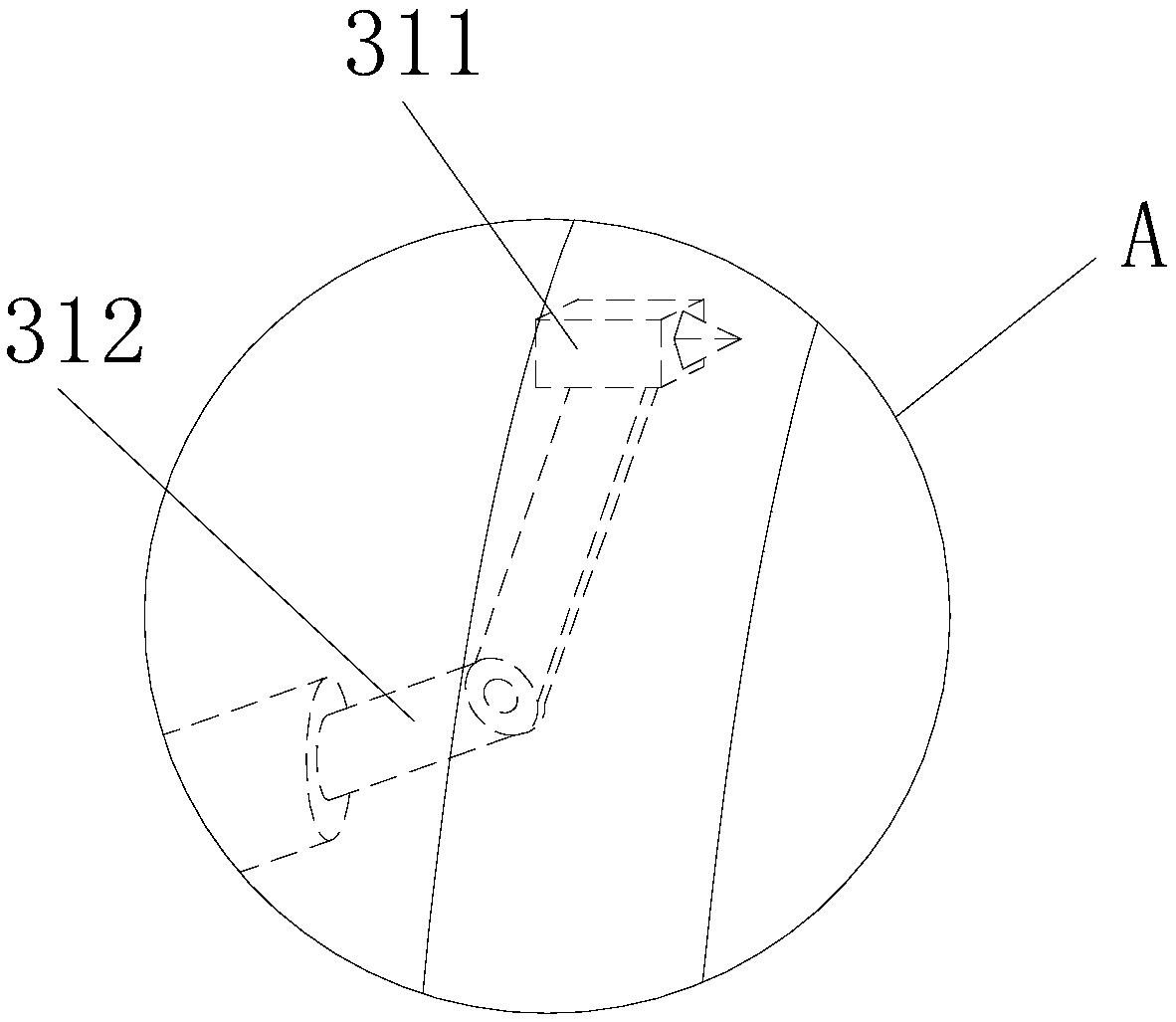

[0024] The lock expansion mechanism 31 includes a conical foot rail 311, an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com