Corrosion fatigue crack propagation testing device with high-temperature high-pressure circulating water and application

A crack propagation test, high temperature and high pressure water technology, used in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc. Maintenance difficulties and other problems, to achieve the effect of high degree of automation, simple operation and convenient maintenance

Inactive Publication Date: 2019-03-19

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

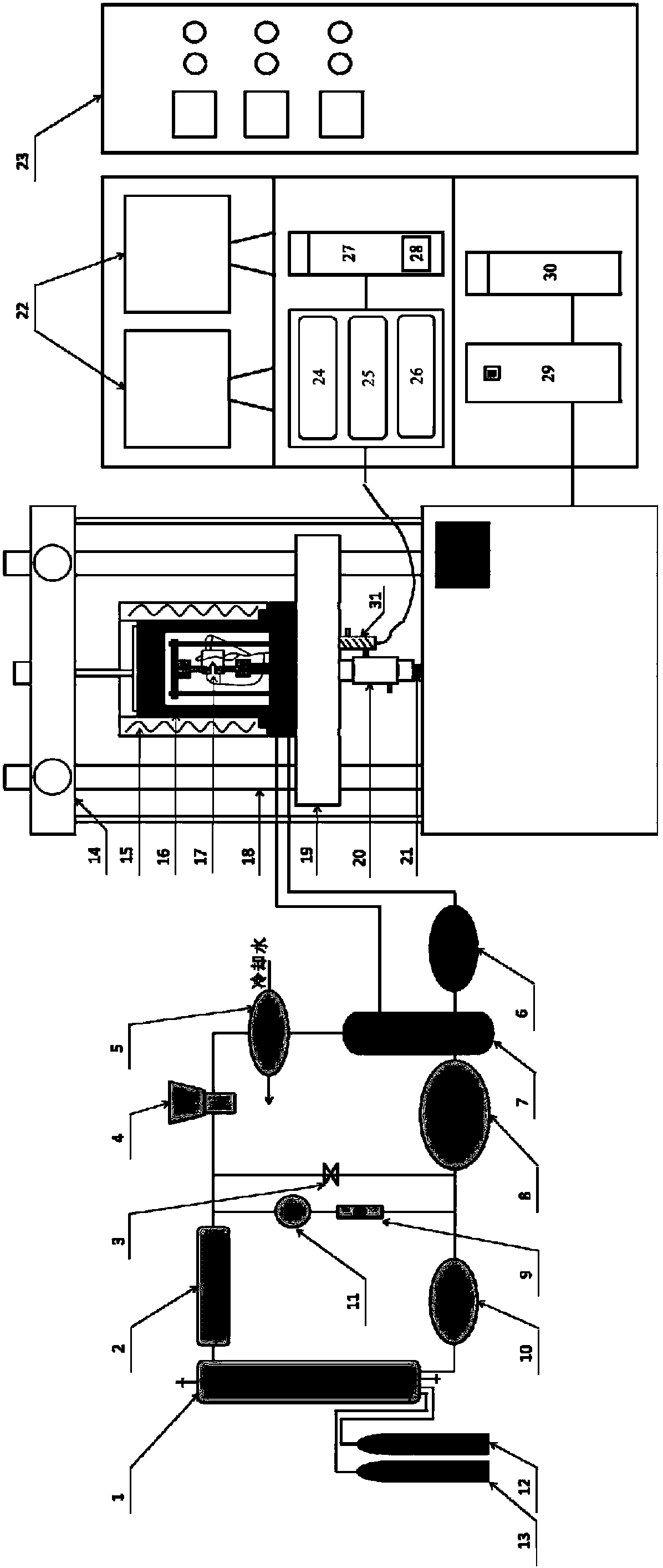

[0004] The purpose of the present invention is to provide a corrosion fatigue crack growth test device with high temperature and high pressure circulating water and its application, which can evaluate the corrosion fatigue crack growth rate of materials in a high temperature and high pressure water environment, and solve the maintenance difficulties and complex structures in the prior art , The operation of the instrument is cumbersome, and the crack length measurement equipment in the conventional air cannot be used in the high temperature and high pressure water environment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

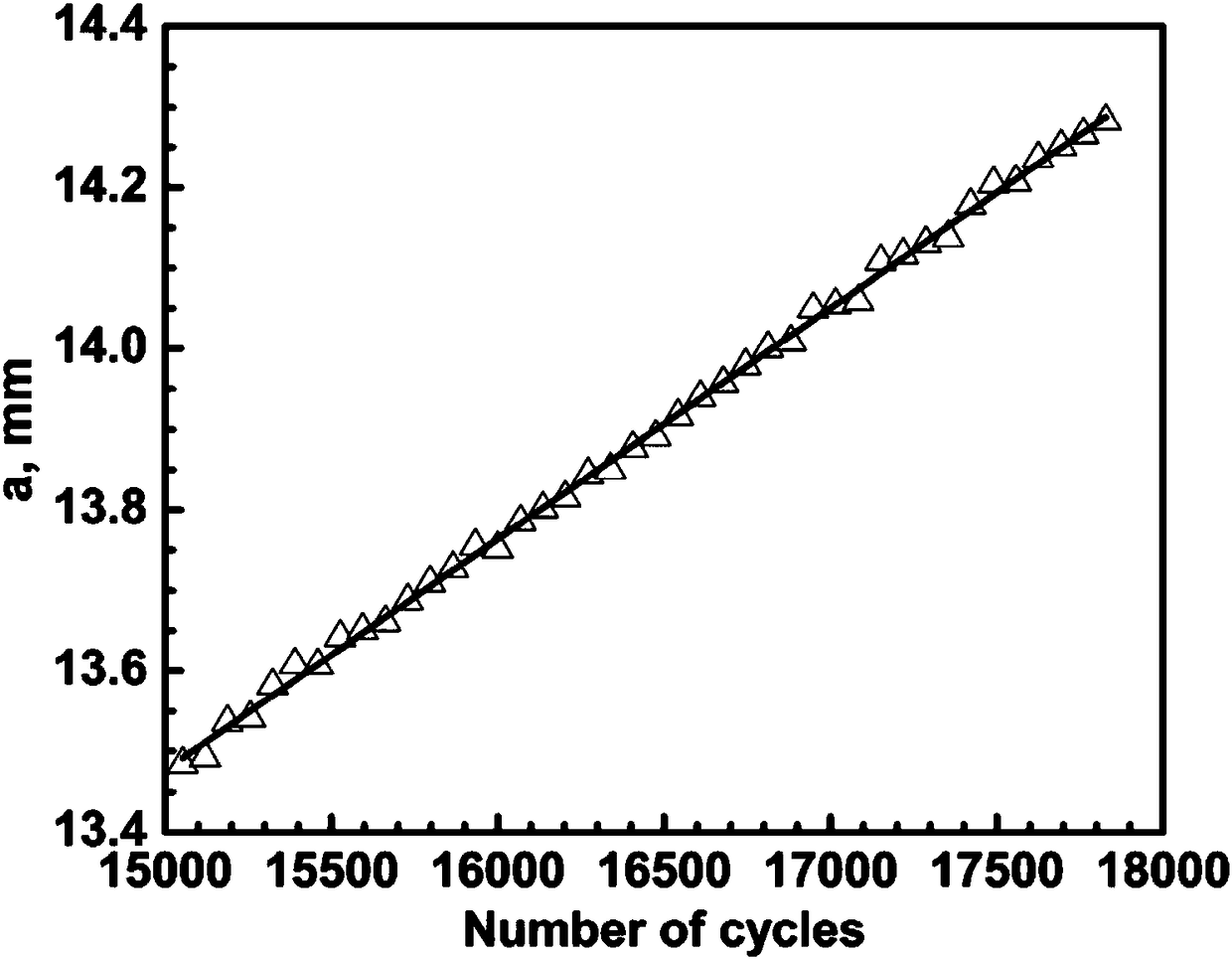

[0060] In this example, the corrosion fatigue crack growth test of forged 316LN stainless steel in a high-temperature and high-pressure water environment with a dissolved oxygen content of less than 5ppb at 320°C, 12MPa, the experiment adopts load control, and the initial ΔK value is 18MPa.m 0.5 , and the stress ratio is 0.05.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of material environmental fatigue experiments, particularly relates to a corrosion fatigue crack propagation testing device with high-temperature high-pressure circulating water and application and aims to solve the problem of in-situ accurate measurement of fatigue crack length and rate in a high-temperature high-pressure water environment. The device is provided with a high-temperature high-pressure water corrosion fatigue crack propagation testing system, a high-temperature high-pressure water circulating system, a high-pressure kettle and a fatigue machine. The high-temperature high-pressure water circulating system is connected with the high-pressure kettle to form a circulating circuit, a CT (compact tension) specimen is connected with a loading portion of the fatigue machine, and the high-temperature high-pressure water corrosion fatigue crack propagation testing system is connected with the CT specimen through a wire and comprises a computer,a nanovolt micro-ohmmeter, a data acquisition switch unit, a direct-current power source, a GPIB board card, a compression seal part and direct-current potential drop testing software. In-situ accurate measurement of fatigue crack length of the CT specimen in the high-temperature high-pressure water environment can be realized.

Description

technical field [0001] The invention belongs to the field of material environment fatigue experiments, more precisely, relates to a corrosion fatigue crack growth test device with high temperature and high pressure circulating water and its application, the test device is used for the fatigue of materials in the simulated nuclear power high temperature and high pressure water environment Crack growth test. Background technique [0002] The damage tolerance method in fatigue design has been widely used in aerospace, electric power, petrochemical and other fields. The basis of the damage tolerance method is the fatigue crack growth law of the material. When the material is served in a harsh environment, the environment-promoted fatigue cracking effect is very important, and the fatigue crack growth rate of the material in the service environment needs to be used as the design basis. In the field of nuclear power, for example, the pressure boundary key equipment (such as: pres...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/32G01N3/02

CPCG01N3/02G01N3/32G01N2203/0005G01N2203/0066G01N2203/0073G01N2203/0226G01N2203/0232

Inventor 吴欣强张兹瑜谭季波王翔韩恩厚柯伟

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com