Cable processing device for optical communication equipment

A processing device and optical communication technology, applied in conductor/cable supply device, cable/conductor manufacturing, circuit, etc., can solve problems such as poor cooling effect and unclear cooling structure, achieve better cooling effect and prolong cooling time , The structure of the device is simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

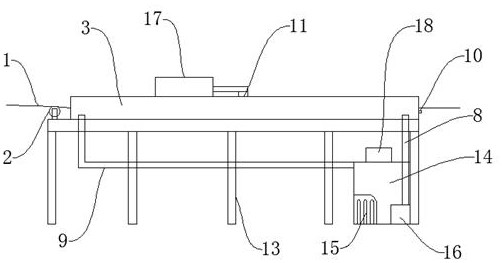

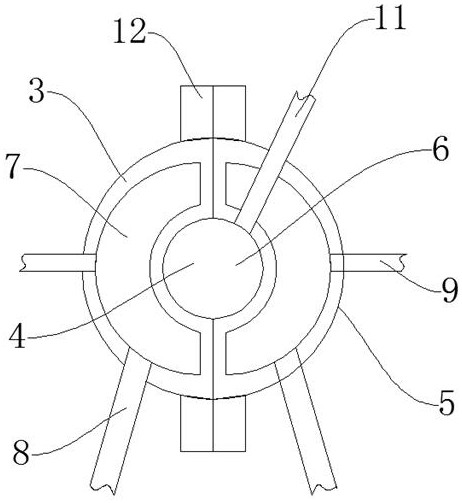

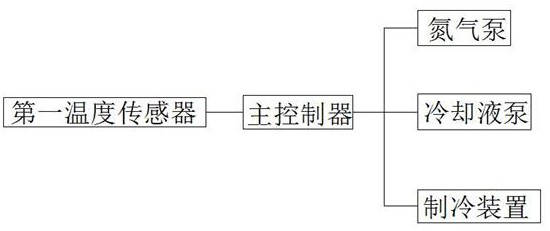

[0038] Such as Figure 1-Figure 8 As shown, a cable processing device for optical communication equipment includes a cable 1, an incoming wire guide wheel 2, a left cooling half-barrel 3 and a left wire-covering tank body 4. The upper part of the incoming wire guide wheel 2 is provided with a cable wire 1, and the cable One side of the line 1 is provided with a left cooling half barrel 3, and the inside of the left cooling half barrel 3 is provided with a left wire-covered tank 4, and the left side of the left wire-covered tank 4 is provided with a right cooling half-barrel 5, and the right cooling half-barrel 5 is provided with a There is a right covered wire groove 6, and the inside of the right cooling half barrel 5 is provided with an internal cold zone pipeline 7, one end of the internal cold zone pipeline 7 is provided with a coolant inlet pipe 8, and the other side of the internal cold zone pipeline 7 is provided with a coolant Outlet pipe 9, a first temperature sensor ...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that in this embodiment, the cable wire 1 is slidably connected with the wire inlet guide wheel 2, the left wire covering groove body 4 is formed in the left cooling half barrel 3, and the right wire covering groove 6 is formed in the Right inside the cooling half bucket 5. This setting can make the device more stable. Further, the semiconductor cooling chip 25 is fixed on the first mounting base 26 through buckles, and the buckling plays a role of fixing, so that the semiconductor cooling chip 25 is easy to install and disassemble.

[0041] The specific working principle of the present invention is: when using the device, when working, the cable 1 enters the left covered wire tank 4 in the left cooling half barrel 3 and the right covered wire in the right cooling half barrel 5 through the wire inlet guide wheel 2 In the cylinder formed by the tank 6, the main controller 18 controls the nitrogen pump 17 to turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com