Current transformer assembly device

A technology for assembling devices and current collectors, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., which can solve the problems of low efficiency of current collectors and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

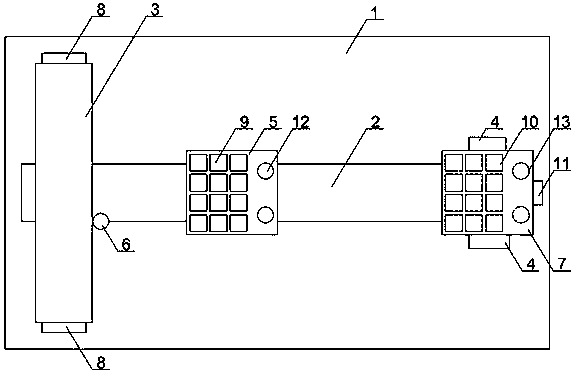

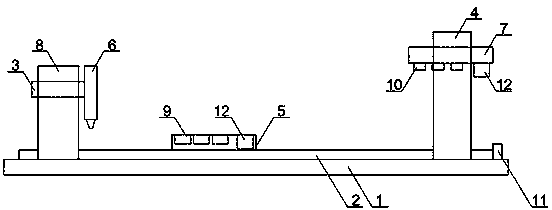

[0018] like Figure 1~2 As shown, a current comparator assembly device includes table 1, x-guiding rail 2, y-guiding rail 3, z-guiding rail 4, lower mold 5, dispensing gun 6 and upper mold 7, x-guiding rail 2, y-guiding The guide rail 3 and the z guide rail 4 are set on the table top 1, the y guide rail 3 is set above one end of the x guide rail 2 through the bracket 8, the z guide rail 4 is set on the other end of the x guide rail 2, and the lower mold 5 is set on the x On the guide rail 2, the upper surface of the lower mold 5 is provided with a number of placement grooves 9 in the form of a matrix, the dispensing gun 6 is set on the y guide rail 3, and the lower mold 5 walks on the x guide rail 2 to the y direction When the guide rail 3 is below, the dispensing gun 6 walks on the y guide rail 3, and its gun head points to each placement groove 9 of the lower mold 5y upwards. The upper mold 7 is arranged on the z guide rail 4, and the lower surface of the upper mold 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com