Tea leaf green removing method

A technology of tea and greening, which is applied in the field of tea production, can solve the problems of green tea shape greenness, yellowing of chlorophyll leaf color, spots or scorched edges, etc., achieve temperature resistance and energy balance, prevent enzymatic reactions, and transfer fast heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

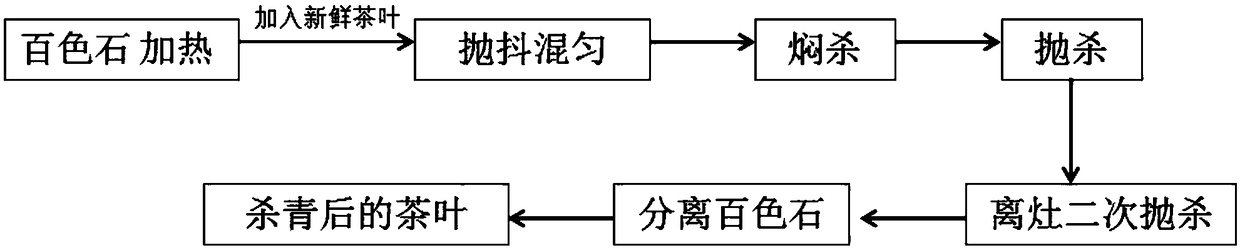

[0016] The process flow chart of this embodiment is as figure 2 shown.

[0017] Clean and dry 2000g of "Baise Stone", then put it in a stainless steel stewing pot with a thermometer, then place the pot on a fire platform and heat it to 250°C.

[0018] Put 200g of fresh tea leaves into the heated pot, mix the tea leaves with "Baise Stone" through the shaking process, and then cover and simmer for 100s until a large amount of water vapor overflows the pot mouth; uncover the pot cover, Throwing continuously until fresh tea leaves lose weight to 45% (throwing time is 3 minutes), then stop heating, move the pot away from the fire platform, use residual heat to carry out second throwing, throwing for 100s until the fresh leaves lose water to 35%. pot, and then quickly use a fan to disperse the water, quickly separate the tea leaves from the "Baise Stone" and then cool them down, so as to obtain the green tea leaves for kneading, which look like image 3 As shown in the figure: it...

Embodiment 2

[0020] Clean and dry 4000g of "Baise Stone", then put it in a stainless steel stewing pot with a thermometer, place it on a fire platform, and heat it to 260°C.

[0021] Put 400g of fresh tea leaves into the heated pot, mix the tea leaves with "Baise Stone" by throwing and shaking, then cover and simmer for 100s, until a large amount of water vapor overflows the pot mouth, uncover the pot cover, and then Throw continuously until fresh tea leaves lose weight to 45% (throwing time is 3min), then stop heating, pot is moved away from the fire platform, utilize residual heat to carry out secondary throwing until fresh leaves lose weight to 33% (leaf color is dark green, Hand-knead the leaves are soft, slightly sticky and knead into a ball. The green gas disappears and the tea leaves are slightly fragrant) out of the pot, and then quickly use a fan to disperse the water and heat, and quickly separate the tea from the "Baise Stone" Heat radiation and cool down to obtain the tea leave...

Embodiment 3

[0023] Clean and dry 6000g of "Baise Stone", then put it in a stainless steel stewing pot with a thermometer, then place the pot on a fire platform and heat it to 280°C.

[0024] Put 600g of fresh tea leaves into the heated pot, mix the tea leaves with "Baise Stone" by throwing and shaking, then cover and simmer for 100s, until a large amount of water vapor overflows the pot mouth, then uncover the pot cover, Then continue to kill until the fresh tea leaves lose weight to 45% (throwing time is 3min), then stop heating, move the pot away from the fire platform, use the residual heat to carry out second throwing, kill for 1min, until the fresh leaves lose weight to 37% (The leaf color is dark green, the leaves are soft when pinched by hand, slightly sticky and form into balls by hand, the green gas disappears, and the tea leaves are slightly fragrant) Take it out of the pot, then use a fan to quickly disperse the water and heat, and quickly mix the tea leaves with After the "Bai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com