Active microalgae functional beverage and preparation method thereof

A technology of functional drinks and microalgae, which is applied in the field of beverages, can solve the problems of easily destroying the active ingredients of chlorella, reduce the nutrient content of beverages, and complicated production steps, so as to achieve easy absorption by the human body, improve nutrition, and rich nutrition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

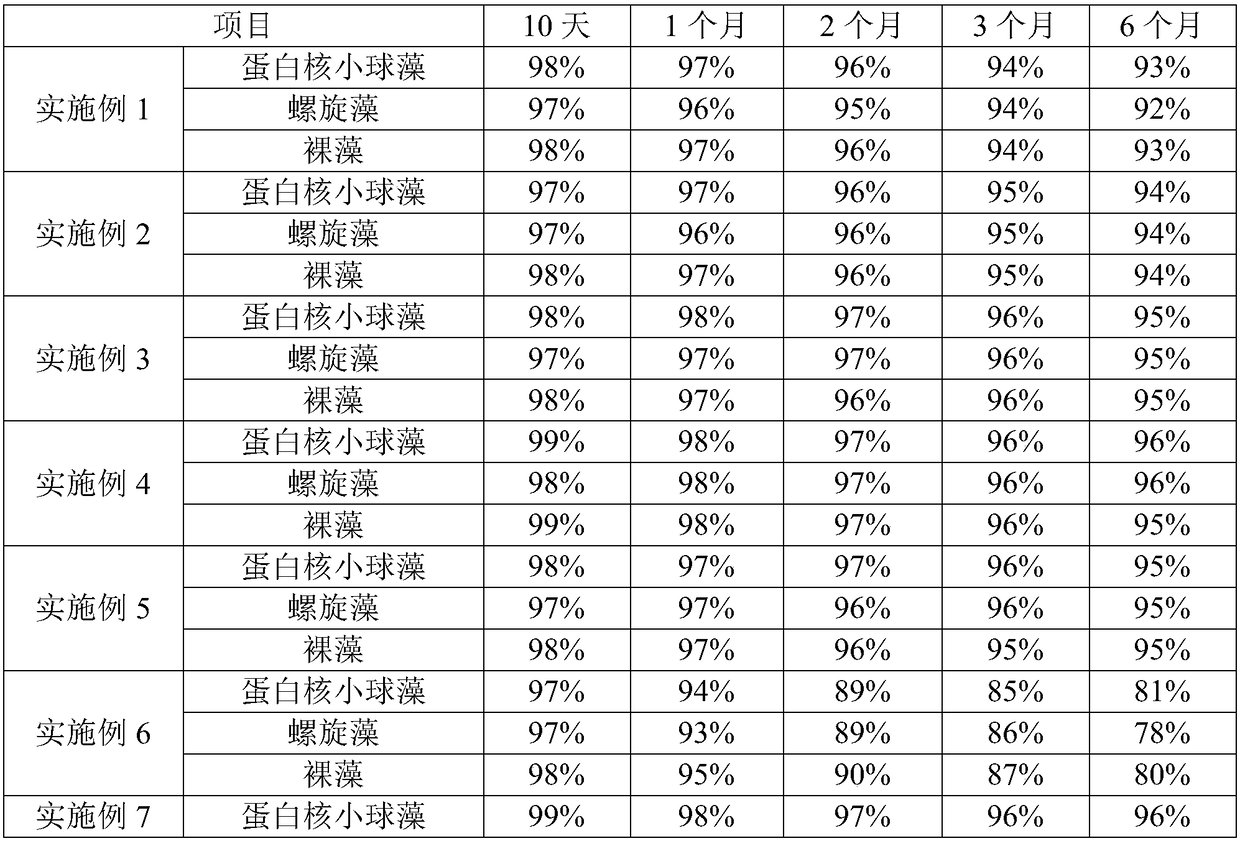

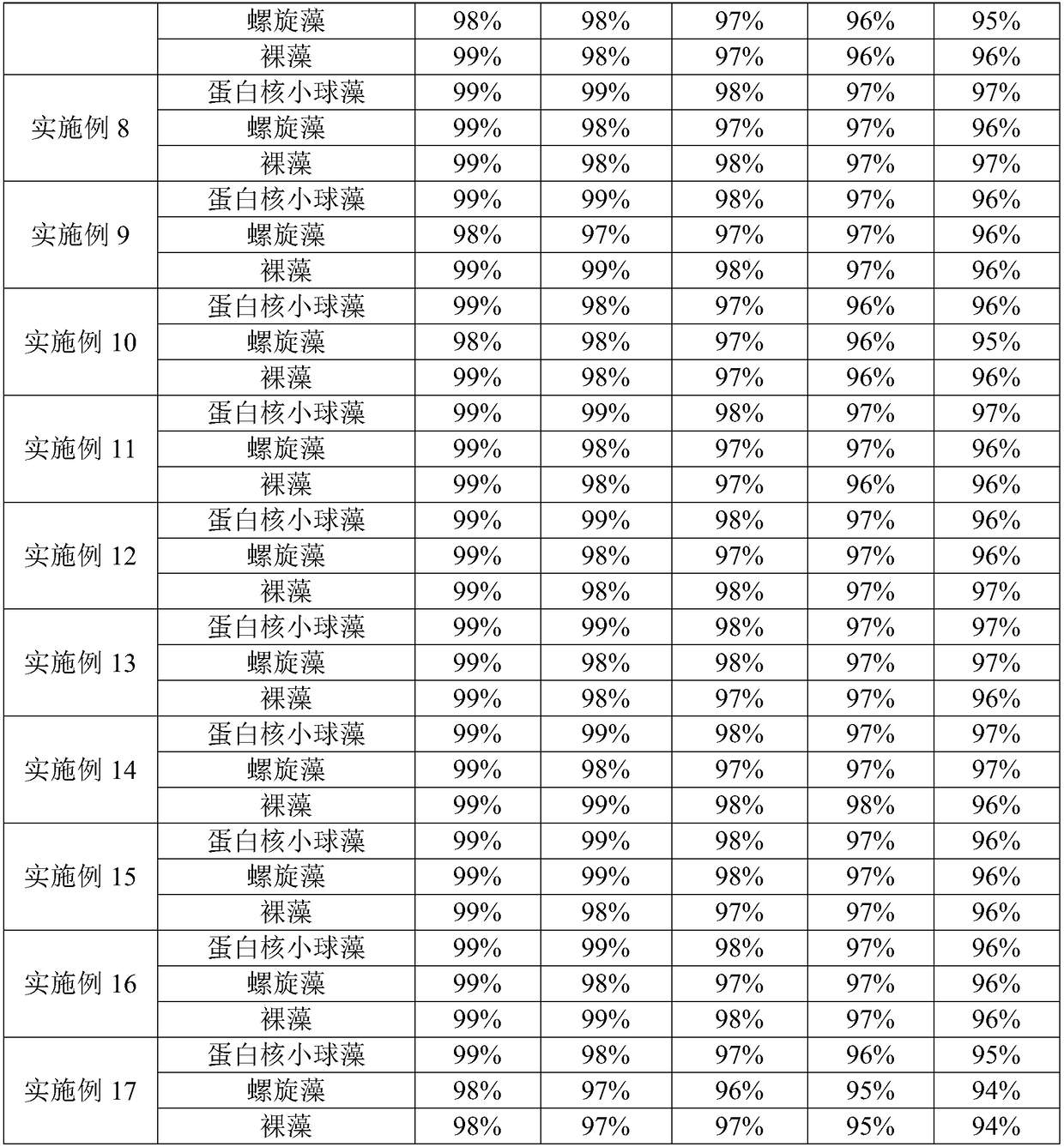

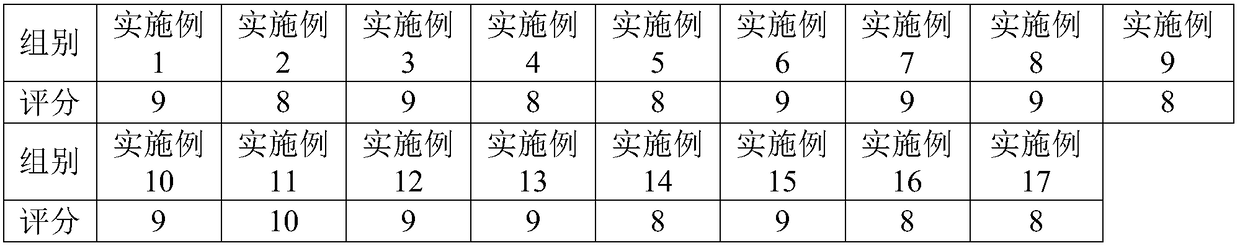

Examples

Embodiment 1

[0039] A kind of active microalgae functional beverage, the preparation method comprises the following steps:

[0040] S1, expanding and cultivating Chlorella pyrenoidosa, Spirulina and Euglena respectively to obtain three kinds of algae liquids, wherein, during the expanding cultivation,

[0041] The expanded cultivation process of the three algae liquids includes: selecting and separating a single microalgal cell under a microscope → culturing a single microalgal cell in 15 mL of medium solution for 10 days to obtain 15 mL of algal liquid → transfer to 85 mL of medium solution Continue culturing for 10 days to obtain 100mL of algae solution → inoculate into 0.9L medium solution for 10 days to obtain 1L of algae solution → inoculate into 4L medium solution for 10 days to obtain 5L Algae liquid → inoculated into 13L medium solution and continued to cultivate for 10 days to obtain 18L of algae liquid → transferred to 782L medium solution and continued to cultivate for 10 days t...

Embodiment 2

[0048] The difference from Example 1 is that in the expanded cultivation of step S1,

[0049] The expanded cultivation process of the three algae liquids includes: selecting and separating a single microalgal cell under a microscope → cultivating a single microalgal cell in 15mL of medium solution for 12 days to obtain 15mL of algae liquid → transfer to 85mL of medium solution Continue culturing for 10 days to obtain 100mL of algae liquid → inoculate into 0.9L medium solution for 12 days to obtain 1L of algae liquid → inoculate into 4L medium solution for 12 days to obtain 5L Algae liquid → inoculated into 13L medium solution and continued to cultivate for 12 days to obtain 18L of algae liquid → transferred to 782L medium solution and continued to cultivate for 12 days to obtain 800L of algae liquid. At the end of the expansion of each stage above, the number of viable microalgae cells is ≥10 6 cells / mL, the number of active microalgae cells in the final obtained algae liquid...

Embodiment 3

[0052] The difference from Example 1 is that in the expanded cultivation of step S1,

[0053] The expanded cultivation process of the three algae liquids includes: selecting and separating a single microalgal cell under a microscope→cultivating a single microalgal cell in 15mL of medium solution for 15 days to obtain 15mL of algal liquid→transferring to 85mL of medium solution Continue culturing for 15 days, obtain 100mL of algae liquid → inoculate into 0.9L medium solution and continue culturing for 15 days, obtain 1L of algae liquid → transfer and inoculate into 4L medium solution for 15 days, obtain 5L Algae liquid → inoculated into 13L medium solution and continued to cultivate for 15 days to obtain 18L of algae liquid → transferred to 782L medium solution and continued to cultivate for 15 days to obtain 800L of algae liquid. At the end of the expansion of each stage above, the number of viable microalgae cells is ≥10 6 cells / mL, the number of active microalgae cells in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com