Special machining tool used for tightening screw caps and air nozzles

A technology of nuts and nozzles, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unfavorable batch production, low efficiency, troubles, etc., and achieve the goals of avoiding wrong wires, reducing costs, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

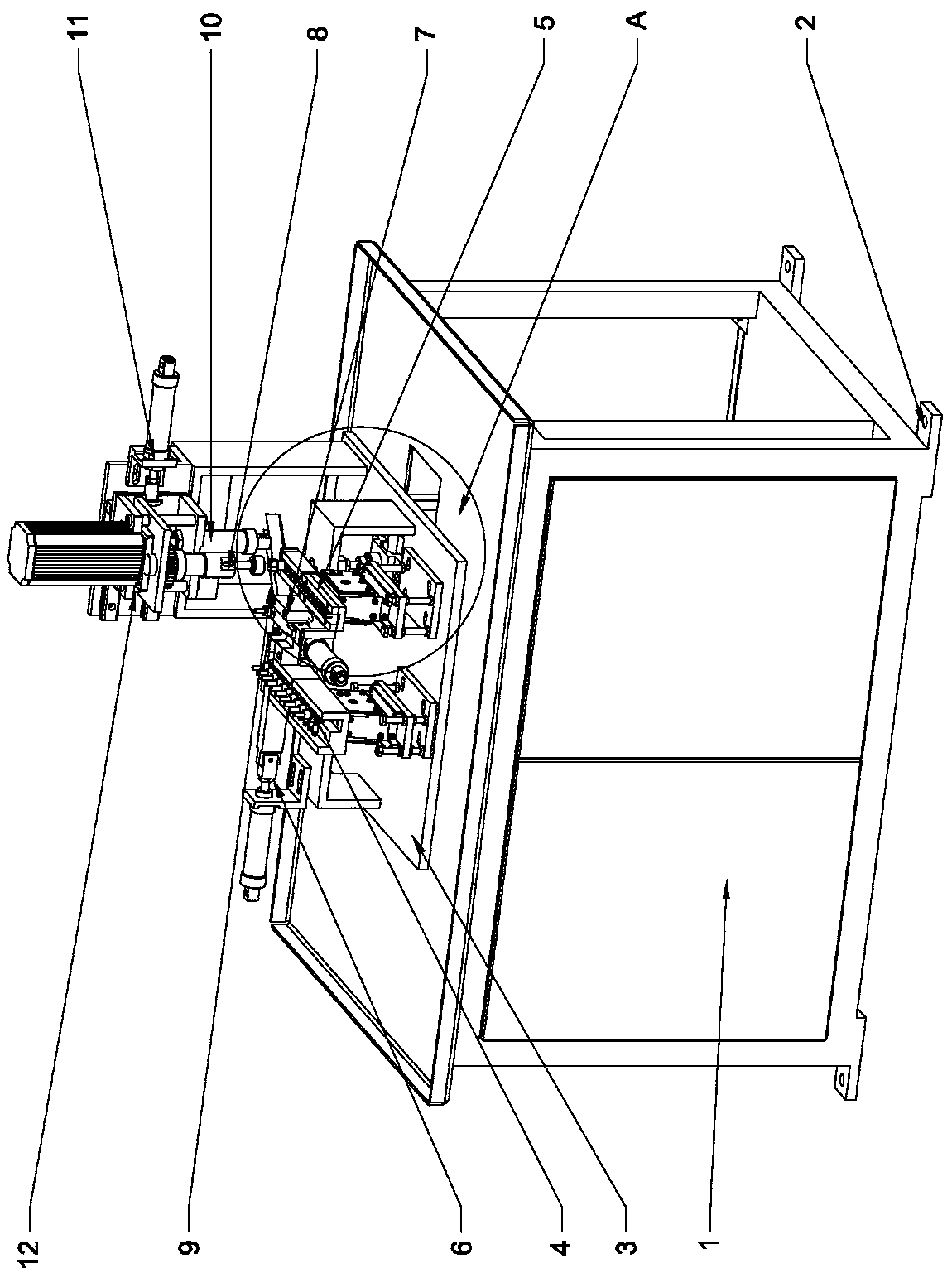

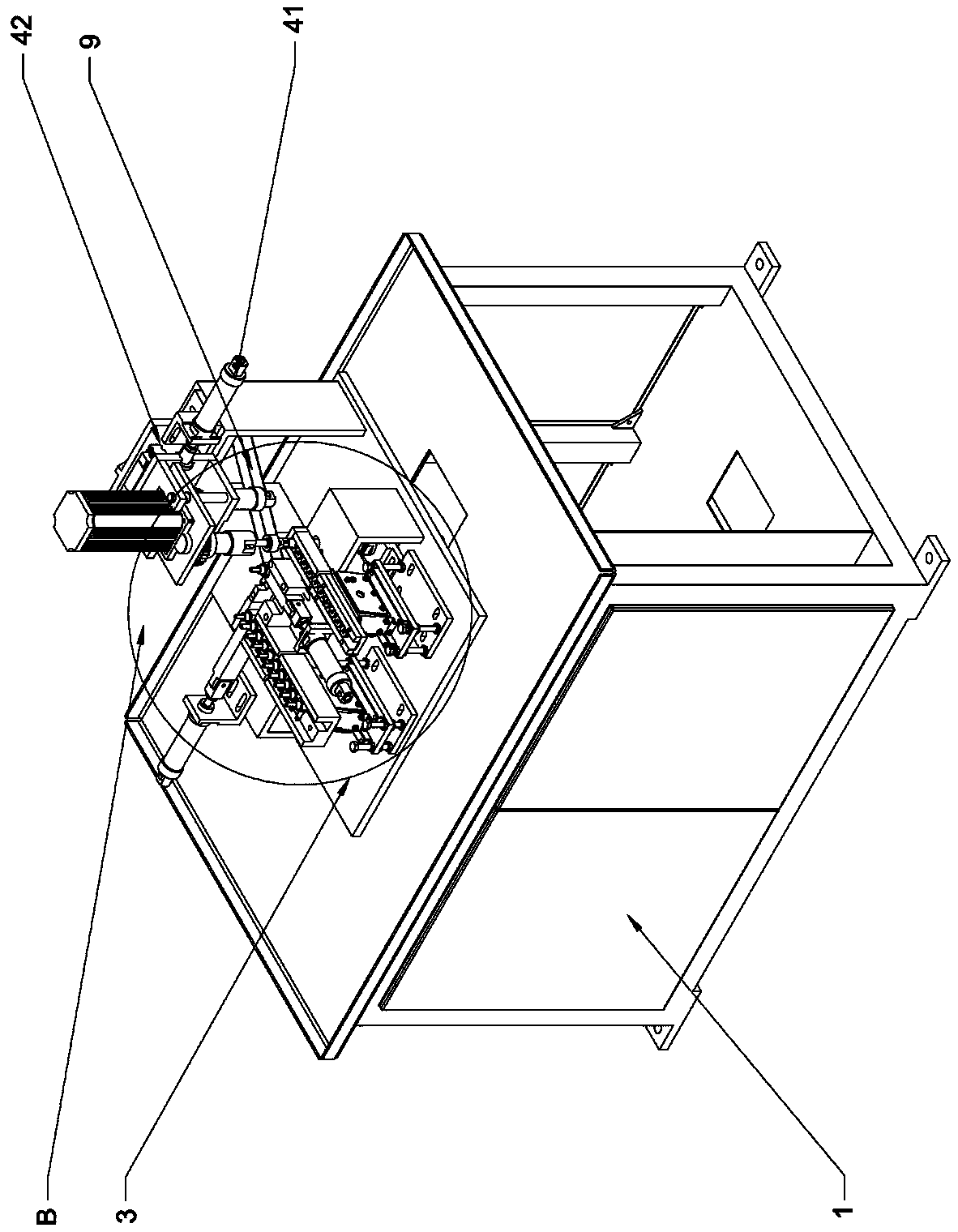

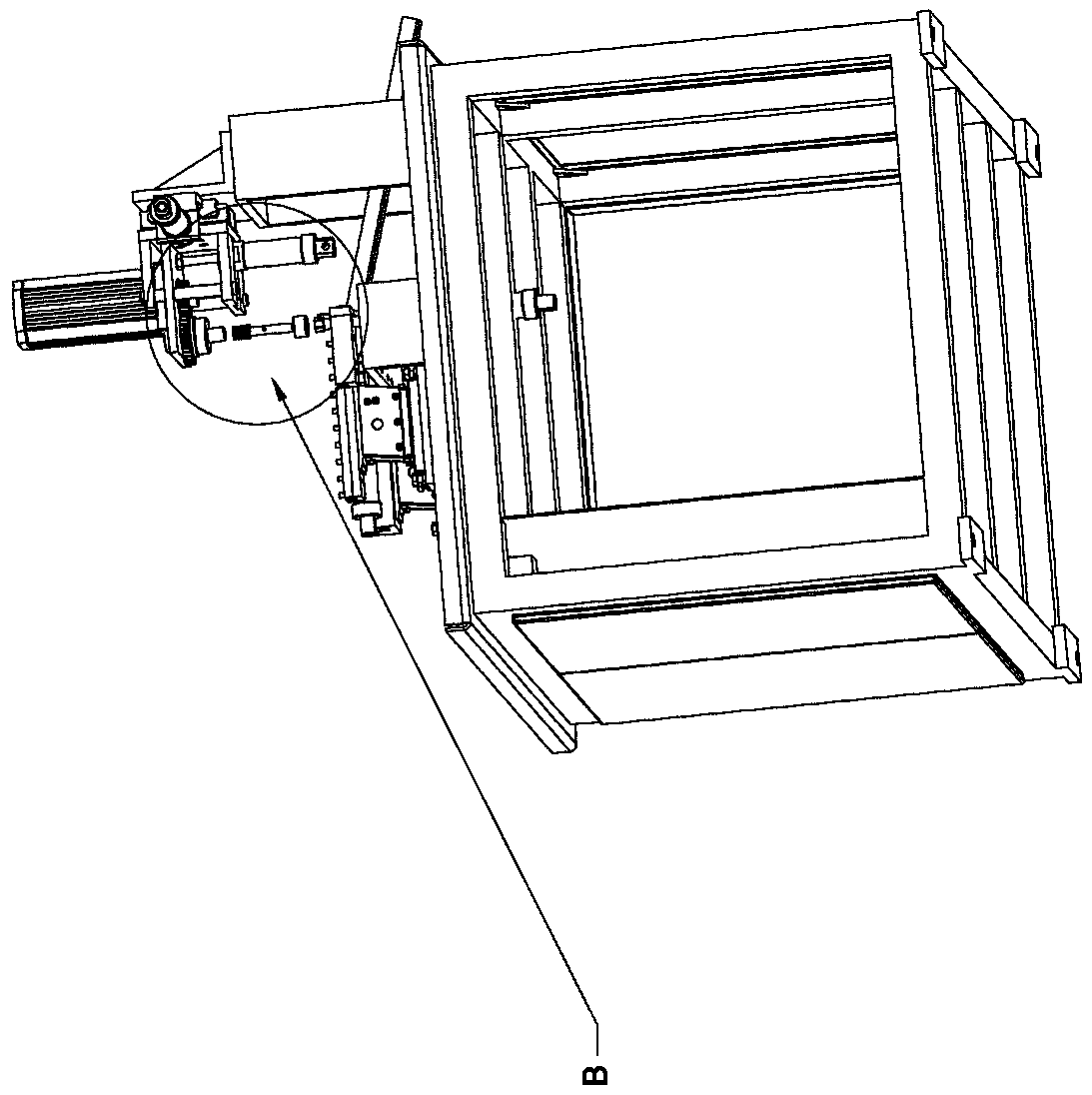

[0023] Such as Figure 1-6As shown, the purpose of the present invention is achieved in this way: a special processing tool for tightening nuts and air nozzles includes a base 1, and the base 1 is directly fixed on the ground by bolts 2 arranged around it; The base 1 is equipped with a working panel 3, and the working panel 3 is equipped with an air nozzle conveying mechanism 4, and a nut conveying mechanism 5 is arranged beside the air nozzle conveying mechanism 4, and the air nozzle conveying mechanism 4 Set at a certain distance from the nut conveying mechanism 5; the end of the air nozzle conveying mechanism 4 is equipped with a displacement and compression cylinder mechanism 6 for pushing the air nozzle 18, and the displacement and compression cylinder 22 and the air nozzle convey The mechanism 4 is vertically arranged; the discharge cylinder mechanism 7 is arranged between the air nozzle conveying mechanism 4 and the nut conveying mechanism 5, and the discharge cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap