A kind of fair-faced concrete and preparation method thereof

A technology of fair-faced concrete and Portland cement, applied in the field of concrete, can solve the problems such as difficulty in obtaining the expected effect, inability to mix the coconut charcoal fibers uniformly, increasing the difficulty of mixing the coconut charcoal fibers, etc., so as to reduce blisters and improve adhesion. Fastness, the effect of improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

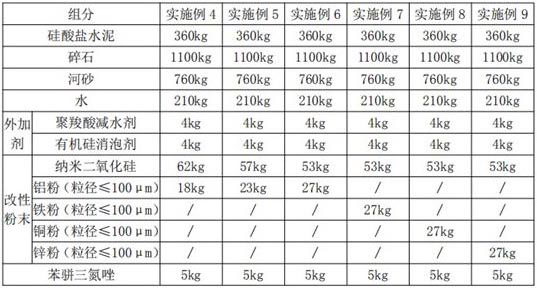

[0056] Embodiment 1-3 all relates to a kind of fair-faced concrete, and its concrete raw material composition is as shown in the table below,

[0057] Table 1.

[0058]

[0059] The modified powder used is formed by mixing nano silicon dioxide and aluminum powder.

Embodiment 1

[0060] The modified powder used in embodiment 1 is processed through the following processes:

[0061] Add the untreated modified powder to the polyvinyl alcohol solution with a concentration of 6wt%, and the mass ratio of the modified powder to the polyvinyl alcohol solution is 1:50; ultrasonically disperse the modified powder evenly for 15 minutes to form a modified powder -Polyvinyl alcohol suspension; then, pressurize the modified powder-polyvinyl alcohol suspension to spray out from the nozzle, and atomize to form droplets with a diameter of ≤500μm; at the same time, use hot air with a temperature of 100-110°C Dry the droplets sprayed from the nozzle, so that the water in the modified powder-polyvinyl alcohol suspension attached to the surface of the aluminum powder particles evaporates rapidly, and a dense polyvinyl alcohol protective layer is formed on the surface of the aluminum powder particles; naturally After cooling to room temperature, sieve to obtain the treated ...

Embodiment 2

[0062] The modified powder used in embodiment 2 is processed through the following processes:

[0063] Add the untreated modified powder to the polyvinyl alcohol solution with a concentration of 6wt%, and the mass ratio of the modified powder to the polyvinyl alcohol solution is 1:50; ultrasonically disperse the modified powder evenly for 18 minutes to form a modified powder -Polyvinyl alcohol suspension; then, pressurize the modified powder-polyvinyl alcohol suspension to spray out from the nozzle, and atomize to form droplets with a diameter of ≤500μm; at the same time, use hot air with a temperature of 100-110°C Dry the droplets sprayed from the nozzle, so that the water in the modified powder-polyvinyl alcohol suspension attached to the surface of the aluminum powder particles evaporates rapidly, and a dense polyvinyl alcohol protective layer is formed on the surface of the aluminum powder particles; naturally After cooling to room temperature, sieve to obtain the treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com