A kind of emulsion for water-based plastic ink facing surface printing and preparation method thereof

A technology of plastic ink and emulsion, applied in the direction of ink, application, household utensils, etc., can solve the problems of very high production process requirements, complex production process, weak adhesion, etc., and achieve good flexibility, good adhesion, and stable system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the water-based plastic ink emulsion facing surface printing comprises the radical emulsion polymerization method under the reversible addition-fragmentation chain transfer, and the radical emulsion polymerization method under the reversible addition-fragmentation chain transfer comprises the following steps:

[0039]Step 1: Dissolve 0.425-0.45 parts by weight of emulsifier in 85-90 parts by weight of deionized water in container one, and then add 15-45 parts by weight of acrylic acid to container one Ester, 15-25 parts by weight of styrene, 20-70 parts by weight of methacrylate and 1.9-2.23 parts by weight of chain transfer agent are uniformly mixed to obtain a pre-emulsion one;

[0040] Step 2: Dissolve 0.05-0.075 parts by weight of emulsifier in 10-15 parts by weight of deionized water in container two, and then add 10-15 parts by weight of acrylic acid to container two Isobornyl or isobornyl methacrylate and mixed uniformly to obtain pre-em...

Embodiment 1

[0051] The water-based plastic ink emulsion facing surface printing includes emulsion particles, the emulsion particles are polymer particles, the polymer in the emulsion particles is a diblock copolymer, and the synthesis of the diblock copolymer The method is a radical emulsion polymerization method under reversible addition-fragmentation chain transfer.

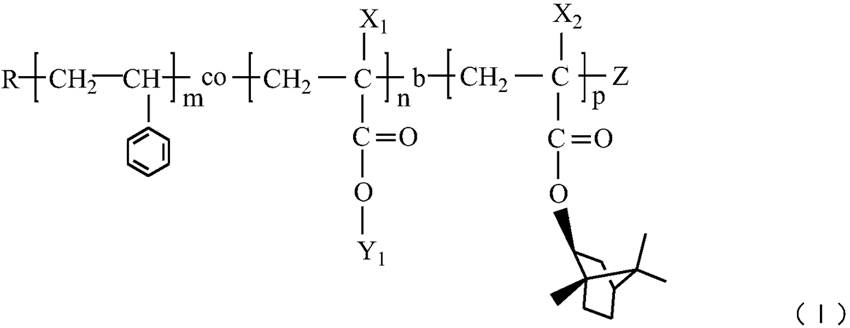

[0052] The polymer in the emulsion micelle is shown in structural formula (I):

[0053]

[0054] Among them, R and Z represent chain transfer agent residues, m, n and p represent the degree of polymerization, co represent random copolymerization, b represent block copolymerization, X 1 represents hydrogen or methyl, X 2 Represents hydrogen or methyl, Y1 represents a hydrocarbon chain.

[0055] One segment of the diblock copolymer can be firmly bonded to plastics, that is, the bonding force between the segment of the diblock copolymer and the plastic is high; the other segment of the diblock copolymer can form a film a...

Embodiment 2

[0080] Including emulsion particles, the emulsion particles are polymer particles, the polymer in the emulsion particles is a diblock copolymer, and the synthesis method of the diblock copolymer is under reversible addition-fragmentation chain transfer free radical emulsion polymerization method.

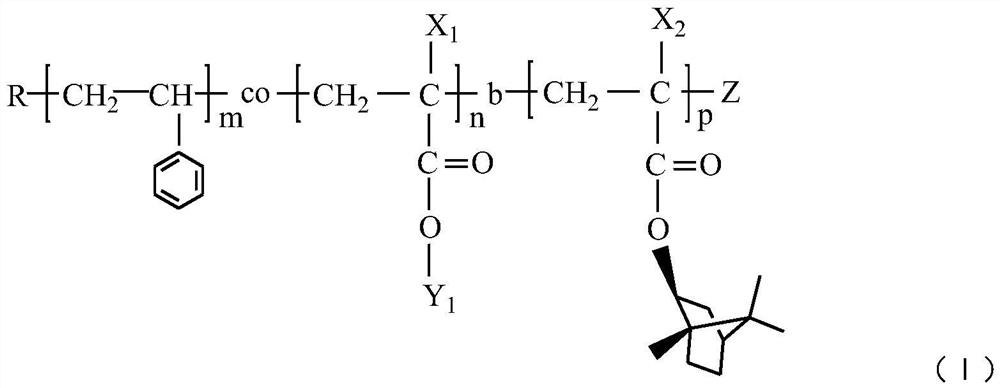

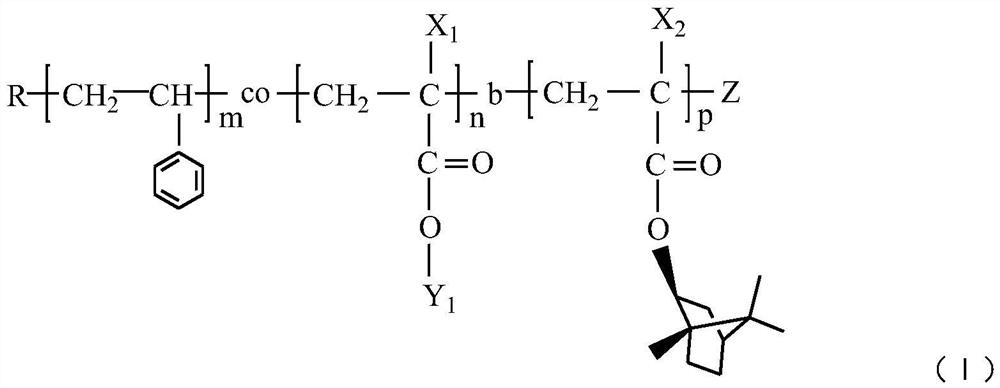

[0081] The polymer in the emulsion micelle is shown in structural formula (I):

[0082]

[0083] Among them, R and Z represent chain transfer agent residues, m, n and p represent the degree of polymerization, co represent random copolymerization, b represent block copolymerization, X 1 represents hydrogen or methyl, X 2 Represents hydrogen or methyl, Y1 represents a hydrocarbon chain.

[0084] One segment of the diblock copolymer can be firmly bonded to plastics, that is, the bonding force between the segment of the diblock copolymer and the plastic is high; the other segment of the diblock copolymer can form a film at room temperature.

[0085] A section of the diblock copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com