Gas infrared catalytic fiber layer and preparation method thereof

A fiber layer and catalytic layer technology, applied in the field of gas infrared catalytic fiber layer and its preparation, can solve the problem of poor adhesion of the catalytic fiber layer, improve the surface temperature uniformity, accelerate the dispersion of heat, and improve the connectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

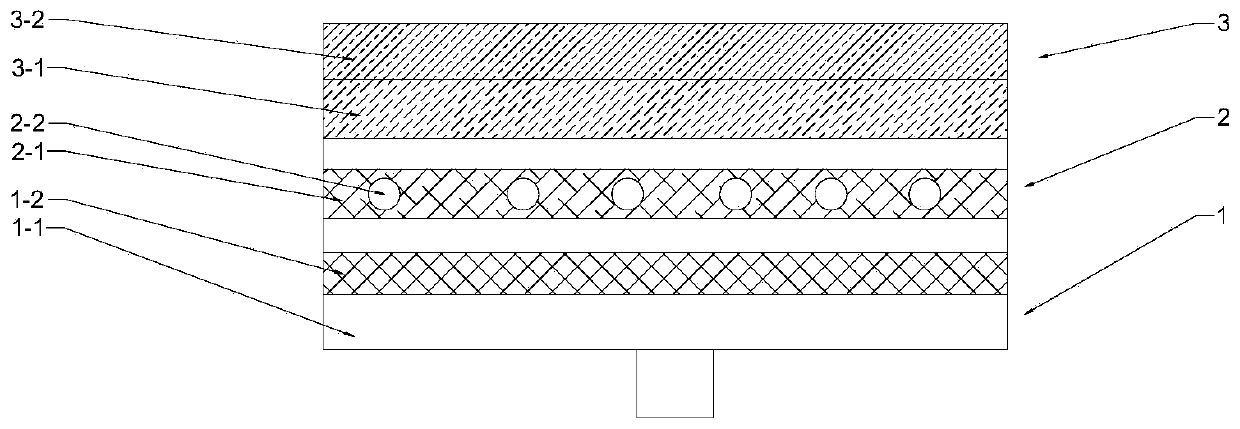

[0025] A gas infrared catalytic fiber layer comprises a graphene surface layer and an alumina catalytic layer, the alumina catalytic layer adopts a platinum-doped active alumina fiber layer, and the graphene surface layer is formed by mixing graphene and alumina.

[0026] The gas infrared catalytic fiber layer is placed in an oxygen-enriched environment and left to stand for 2 hours before use.

[0027] The preparation method of the gas infrared catalytic fiber layer comprises the following steps:

[0028] Step 1, adding platinum chloride to absolute ethanol and stirring evenly to form a platinum alcohol solution, the concentration of the platinum chloride in absolute ethanol is 10g / L, and the stirring speed is 1000r / min;

[0029] Step 2, adding aluminum chloride to the platinum alcohol solution and stirring evenly to form a platinum aluminum alcohol solution, the quality of the aluminum chloride is 400% of the platinum chloride, and the stirring speed is 1000r / min;

[0030] ...

Embodiment 2

[0039] A gas infrared catalytic fiber layer comprises a graphene surface layer and an alumina catalytic layer, the alumina catalytic layer adopts a platinum-doped active alumina fiber layer, and the graphene surface layer is formed by mixing graphene and alumina.

[0040] The gas infrared catalytic fiber layer is placed in an oxygen-enriched environment and left to stand for 4 hours before use.

[0041] The preparation method of the gas infrared catalytic fiber layer comprises the following steps:

[0042] Step 1, adding platinum chloride to absolute ethanol and stirring evenly to form a platinum alcohol solution, the concentration of the platinum chloride in absolute ethanol is 30g / L, and the stirring speed is 2000r / min;

[0043] Step 2, adding aluminum chloride to the platinum alcohol solution and stirring evenly to form a platinum aluminum alcohol solution, the quality of the aluminum chloride is 700% of the platinum chloride, and the stirring speed is 2000r / min;

[0044] ...

Embodiment 3

[0053] A gas infrared catalytic fiber layer comprises a graphene surface layer and an alumina catalytic layer, the alumina catalytic layer adopts a platinum-doped active alumina fiber layer, and the graphene surface layer is formed by mixing graphene and alumina.

[0054] The gas-fired infrared catalytic fiber layer is put into an oxygen-enriched environment and left to stand for 3 hours before use.

[0055] The preparation method of the gas infrared catalytic fiber layer comprises the following steps:

[0056] Step 1, adding platinum chloride to absolute ethanol and stirring evenly to form a platinum alcohol solution, the concentration of the platinum chloride in absolute ethanol is 20g / L, and the stirring speed is 1500r / min;

[0057] Step 2, adding aluminum chloride to the platinum alcohol solution and stirring evenly to form a platinum aluminum alcohol solution, the quality of the aluminum chloride is 600% of the platinum chloride, and the stirring speed is 1500r / min;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com