Lower conducting dome of inorganic electroluminescent display and production method thereof

A manufacturing method and bottom electrode technology, applied in the direction of electroluminescent light source, electric light source, light source, etc., can solve the problems of poor conduction, low temperature resistance of the bottom electrode, etc., and achieve low cost, high withstand voltage, and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

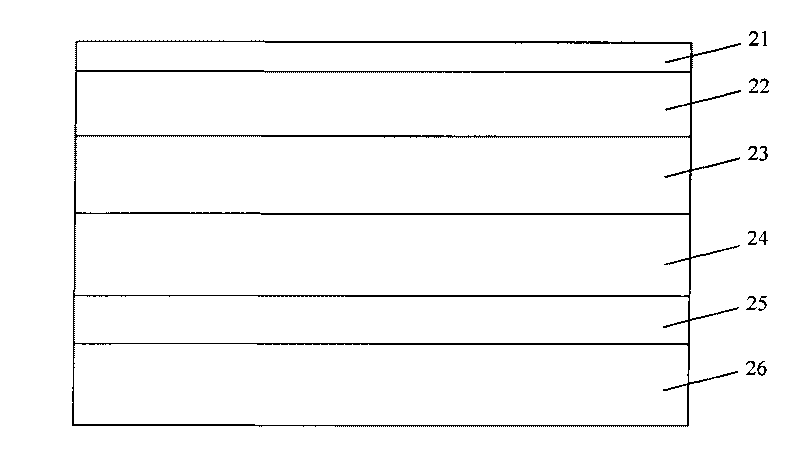

[0017] Such as figure 2 As shown, an inorganic electroluminescence display comprises a layer of glass 6, a layer of bottom electrode 5 is arranged on the glass 6, and a layer of lower dielectric layer 4 is arranged on the top of the bottom electrode 5, and the lower dielectric layer 4 is arranged on the bottom electrode 5. A light-emitting layer 3 is arranged on the upper part of the medium layer 4 , an upper dielectric layer 2 is arranged on the upper part of the light-emitting layer 3 , and an upper electrode 1 is arranged on the upper part of the upper dielectric layer 2 .

[0018] Further, the material of the bottom electrode 5 is Ti-Au composite film.

[0019] Further, the upper electrode 1 is ITO.

[0020] Further, the upper dielectric layer 2 is selected from Al 2 o 3 , or Ta 2 o 5 .

[0021] Further, the light-emitting layer 3 is selected from a mixture of ZnO and Mn.

[0022] Further, the material of the lower dielectric layer 4 is BaSrTO 3 .

Embodiment 2

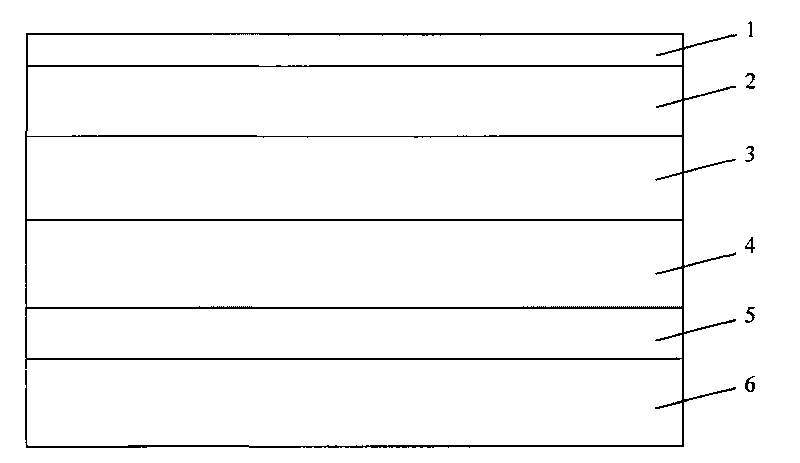

[0024] Such as figure 2 As shown, the present invention also provides a method for making the bottom electrode of an inorganic electroluminescent display. First, the TFT glass 6 is cleaned and dried, and the glass substrate 6 is placed in an electron beam evaporation device, and the vacuum is evacuated to 1.5×10 -3 Pa-3.0×10 -3 The air pressure of Pa, glass substrate 6 temperature is heated to 130-180 ℃, and evaporation rate is Using 99.9% pure Ti target material, 45- Thick Ti film, then turn the Au target to the evaporation position, the purity of Au is 99.9%, and also evaporate 140- Thick Au film, after the amplified gas is taken out from the vacuum chamber, the bottom electrode 5 of the device is completed.

[0025] Further, the glass substrate 6, the bottom electrode 5, the lower dielectric layer 4, and the luminescent layer 3 are heated together by means of electric heating wire heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com