Halogen-free flame-retardant polypropylene (PP) material and preparation method thereof

A flame-retardant polypropylene and polypropylene resin technology, applied in the field of polymer materials, can solve the problems of long-term high-temperature yellowing of halogen-free flame-retardant materials, impact on product aesthetics, yellowing, etc., and achieve efficient free radical capture Functional, excellent long-term thermal stability, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5、 comparative example 1-6

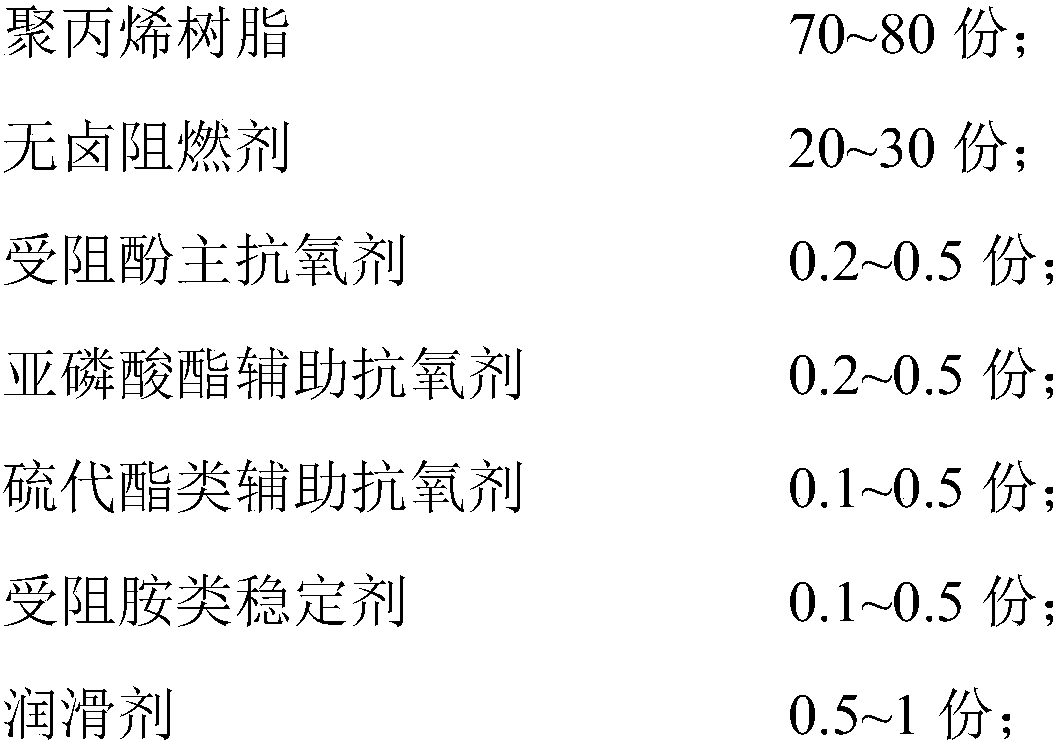

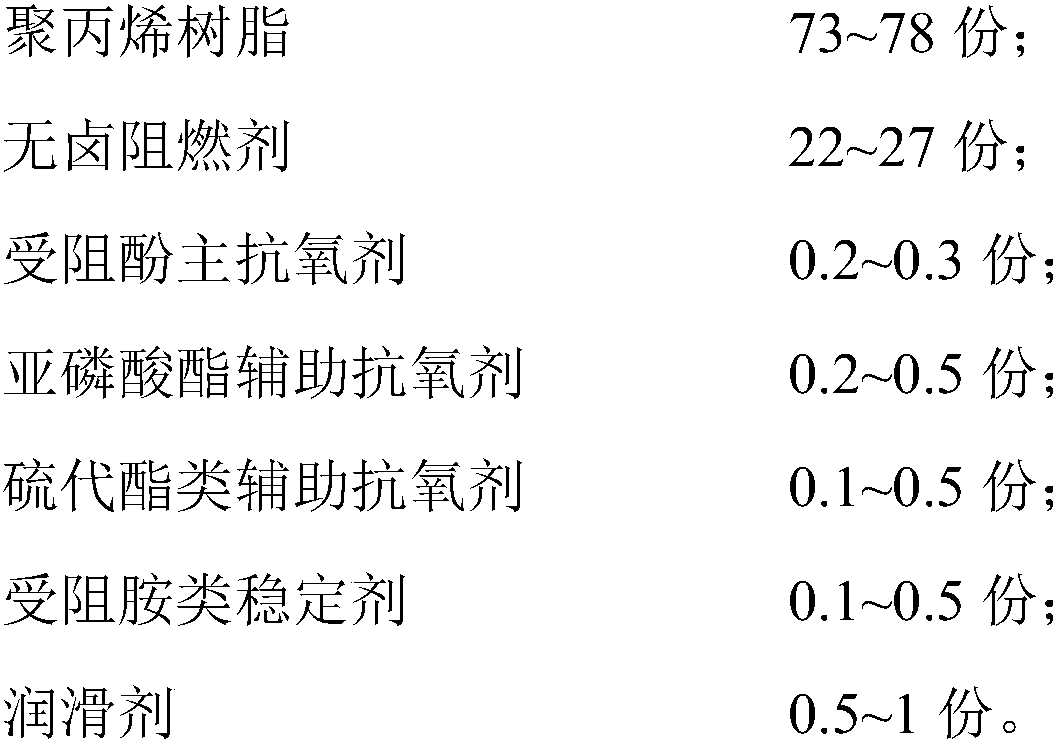

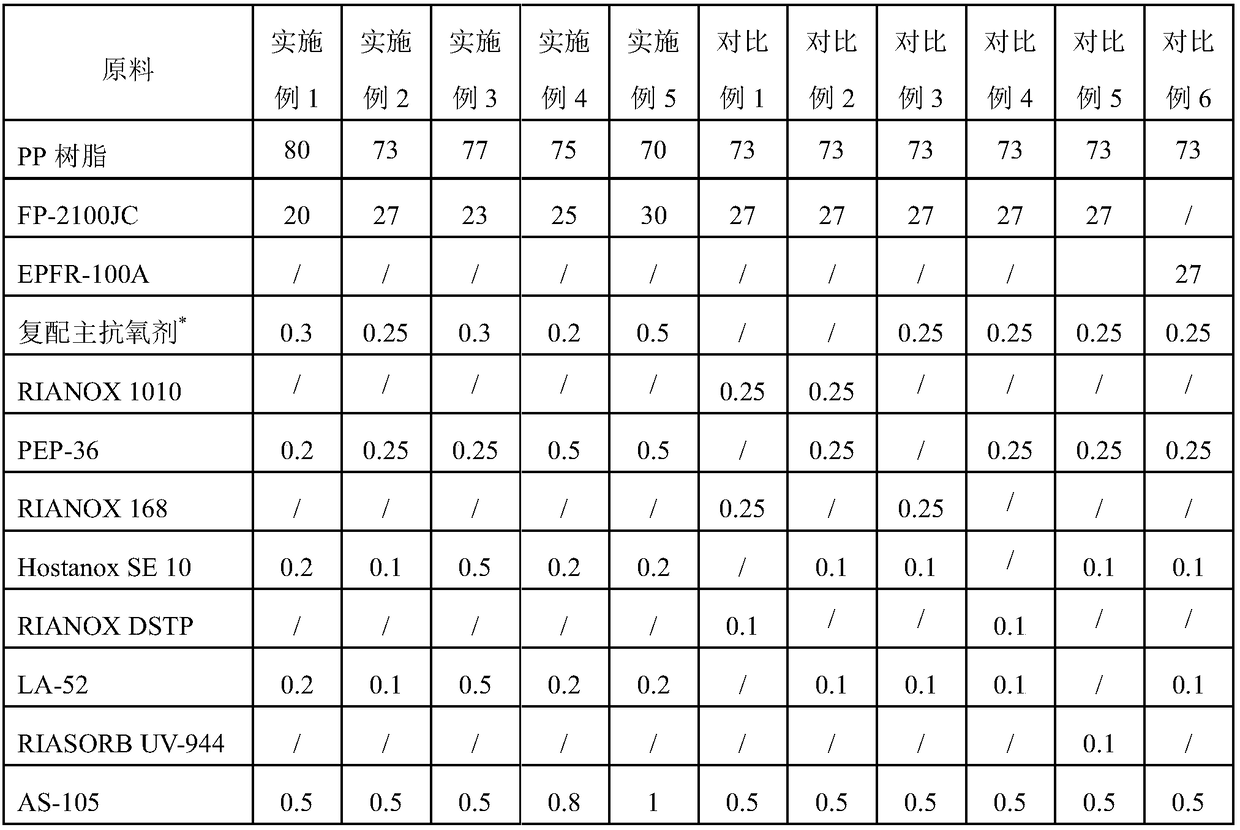

[0042] This example provides a halogen-free flame-retardant polypropylene material and a preparation method thereof. The raw material formula is shown in Table 1 in parts by weight:

[0043] Table 1 Formulation composition of halogen-free flame-retardant polypropylene

[0044]

[0045] * Note: The ratio of compounded main antioxidant AO-20: AO-80 is 1:1.

[0046] Mix the above raw materials in a high-speed mixer for 5 minutes and then place them in a twin-screw extruder. The zone temperature is 180-190°C, the five-zone temperature is 180-190°C, the machine head temperature is 180-200°C, and the host speed is 300-450 rpm; extruding and granulating can obtain long-term high-temperature yellowing-resistant halogen-free flame-retardant polypropylene Material.

[0047] Effect test

[0048] Using the halogen-free flame-retardant polypropylene material prepared in Examples 1-5 and Comparative Examples 1-4, inject the prepared long-term high-temperature yellowing-resistant halog...

Embodiment 1

[0054] The flame retardant rating of Example 1 and the flame retardant rating after the thermal oxygen aging test are V1, which is slightly worse than other examples, and the mechanical properties of Example 5 are slightly worse than other examples. The possible reason is that the flame retardant and The ratio of the high-efficiency compound antioxidant system of the hindered phenol primary antioxidant, the high-temperature-resistant hydrolysis-resistant phosphate auxiliary antioxidant, the thioester auxiliary antioxidant and the weakly basic hindered amine stabilizer It affects the flame retardancy and mechanical properties, but Examples 1-5 can achieve long-term high-temperature yellowing resistance, while maintaining good flame retardancy and good mechanical properties.

[0055] In Comparative Example 1, compared with Example 2, it adopts an ordinary antioxidant system, and the color difference value after the thermo-oxidative aging test is larger; Compared with Example 2, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap