Coal pillar reinforcement system for gob-side entry driving and use method thereof

A coal pillar and fixing ring technology, applied in earth-moving drilling, ground mining, mining equipment, etc., can solve the problems of flattening, difficult grouting, inaccurate width reservation, etc., to improve integrity, improve stability and Bearing capacity, reducing the effect of roadway deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention proposes a coal pillar reinforcement system for roadway driving along the goaf and its use method. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below with reference to specific embodiments.

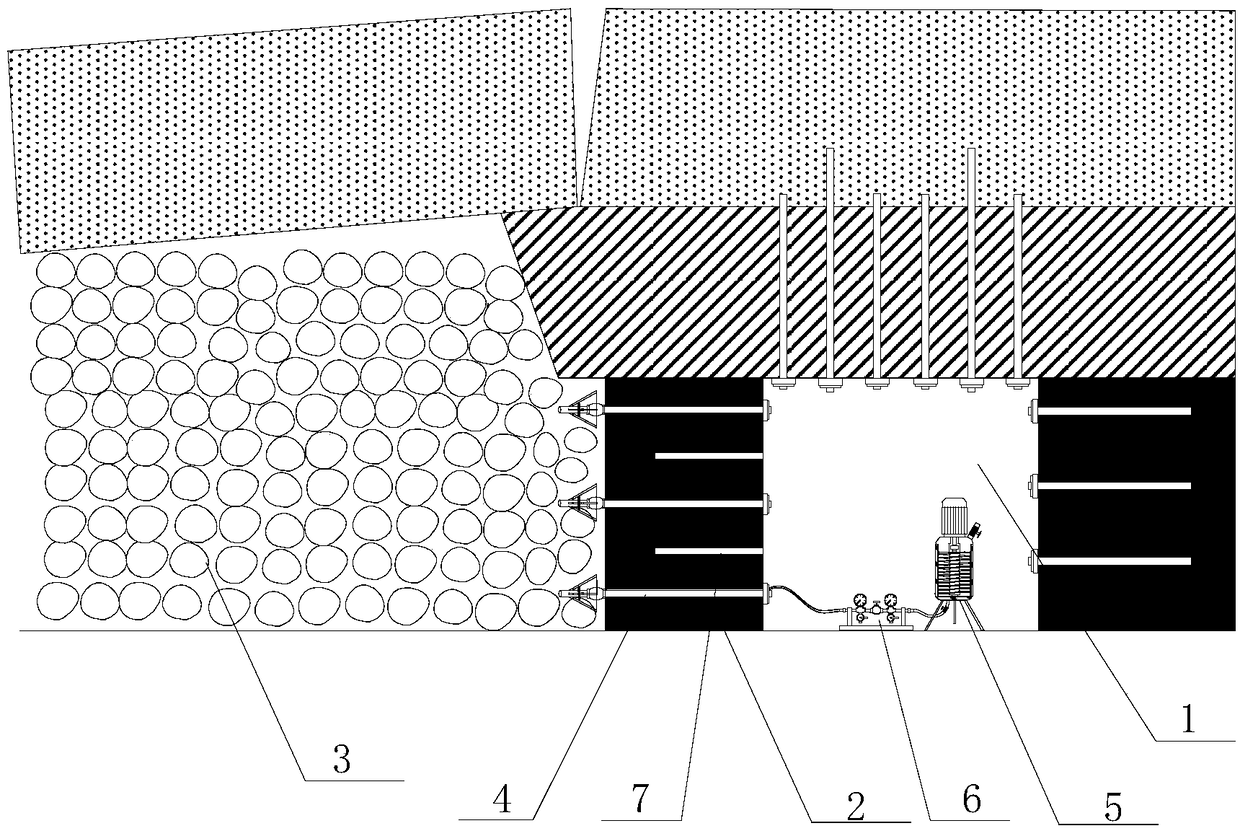

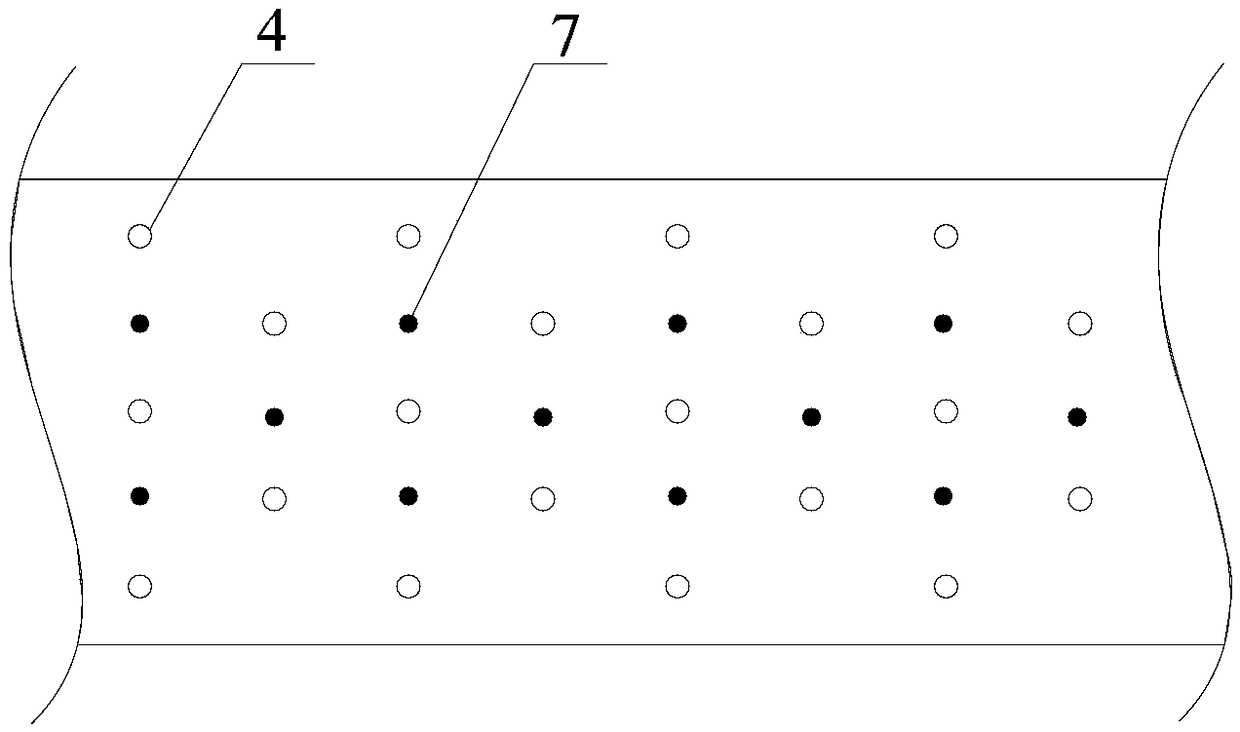

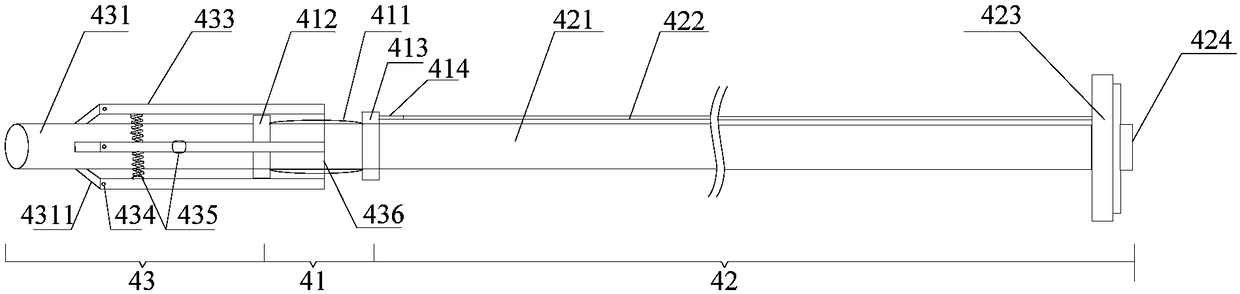

[0040] The present invention is a coal pillar reinforcement system for roadway driving along the goaf, which includes a coal pillar reinforcement anchor cable 4, a grouting bore 7, a grouting machine 5, and a grouting monitoring device 6. Combine figure 1 , figure 2 As shown, the arrangement of coal pillar reinforcement anchor cables is as follows: three coal pillars are laid in the first row to reinforce the anchor cables 4, and two coal pillars are laid in the second row to reinforce the anchor cables 4. 1.5m×1.5m. The grouting borehole 7 is drilled between the boreholes of the coal pillar reinforcement anchor cable 4, and the depth of the grouting boreho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com