Method for constructing salt-cavern gas storage base

A construction method and technology for gas storage, which are applied in the fields of earthwork drilling, fluid extraction, mining equipment, etc., can solve the problems of high cost of gas storage, low cost performance, restricting the enthusiasm of salt cavern gas storage, etc., so as to speed up the dissolution rate , the effect of increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description will be given in conjunction with the accompanying drawings.

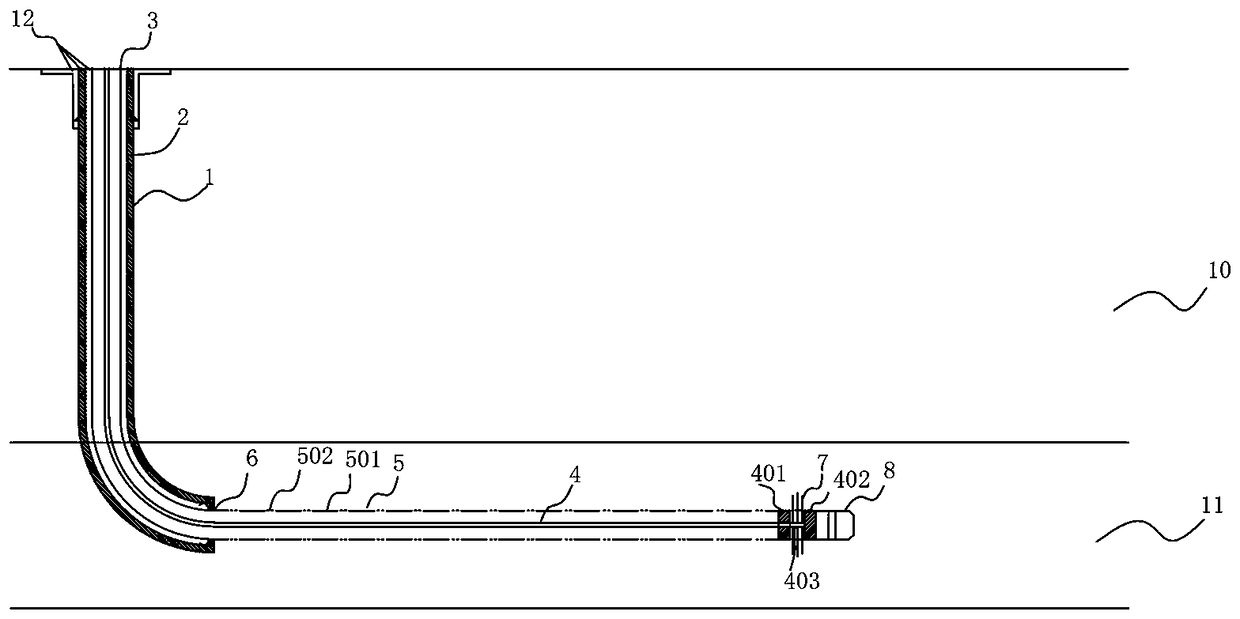

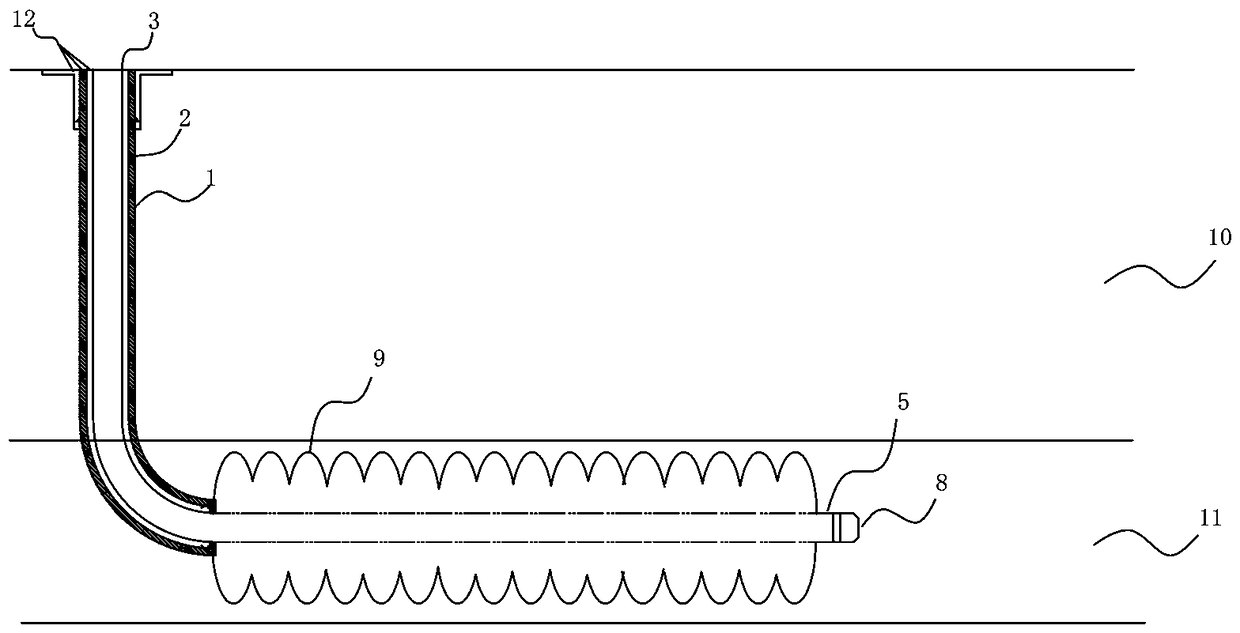

[0022] A construction method of a salt cavern gas storage, such as figure 1 , figure 2 shown, including the following steps:

[0023] Step 1. Drill an L-shaped horizontal well from the ground. The L-shaped horizontal well includes a vertical well section, an inclined well section connected with the vertical well section, and a horizontal well section connected with the inclined well section, and the upper part of the vertical well section and the inclined well section is located in the formation 10, The lower part of the inclined well section and the horizontal well section of the L-shaped horizontal well are located in the middle of the salt layer 11. In other embodiments, for a salt layer with a relatively large thickness, part of the inclined well section can also be set in the salt layer;

[0024] Step 2. Set the upper casing string 3 in the vertical well section and the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com