Self-cleaning dust filtering chimney

A self-cleaning and dust-filtering technology, applied in the field of chimneys, can solve the problems of difficult air filter cleaning, time-consuming and labor-intensive work, and high-altitude operations, so as to improve the dust collection effect, prolong the cleaning cycle, and improve the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

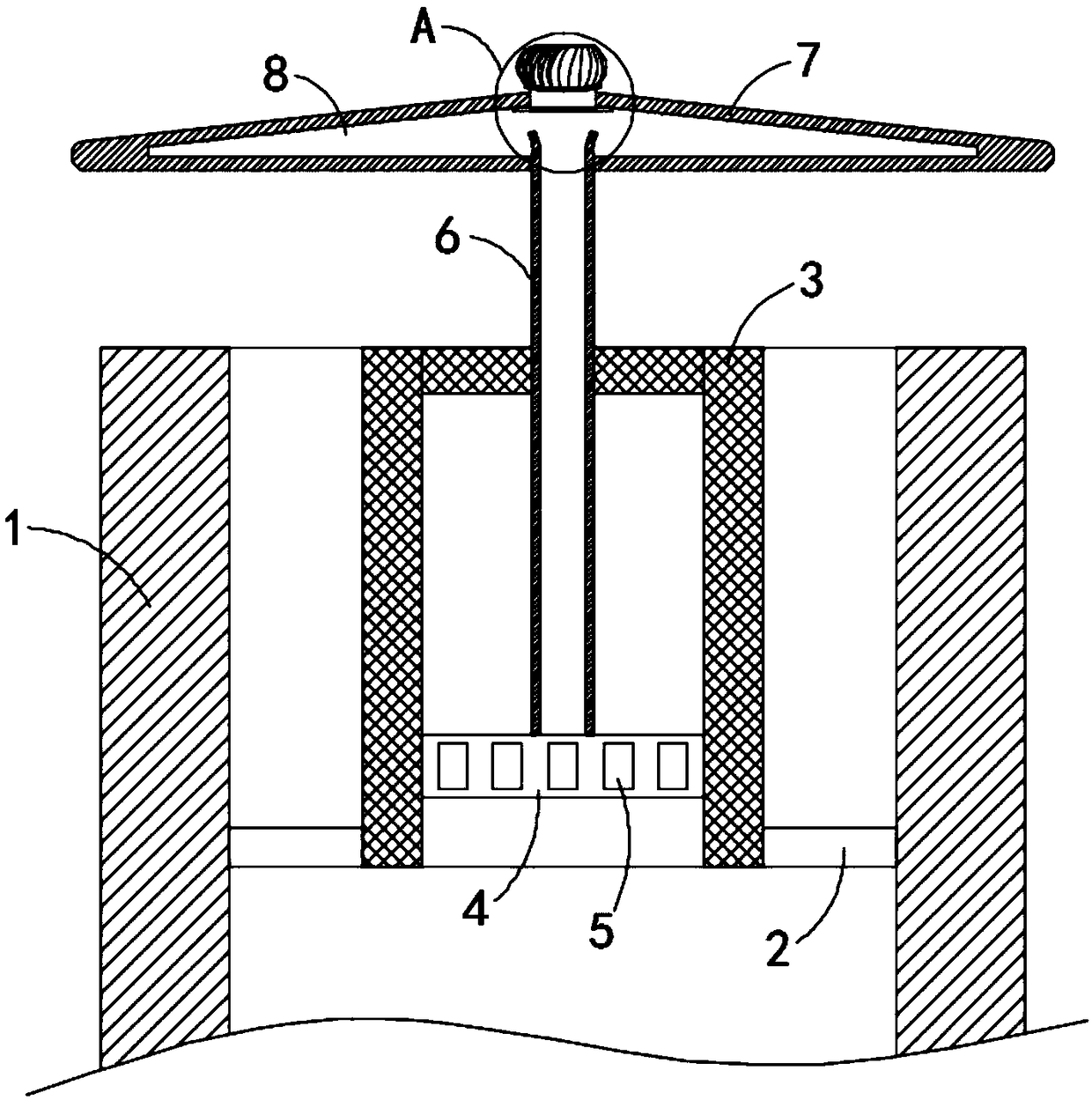

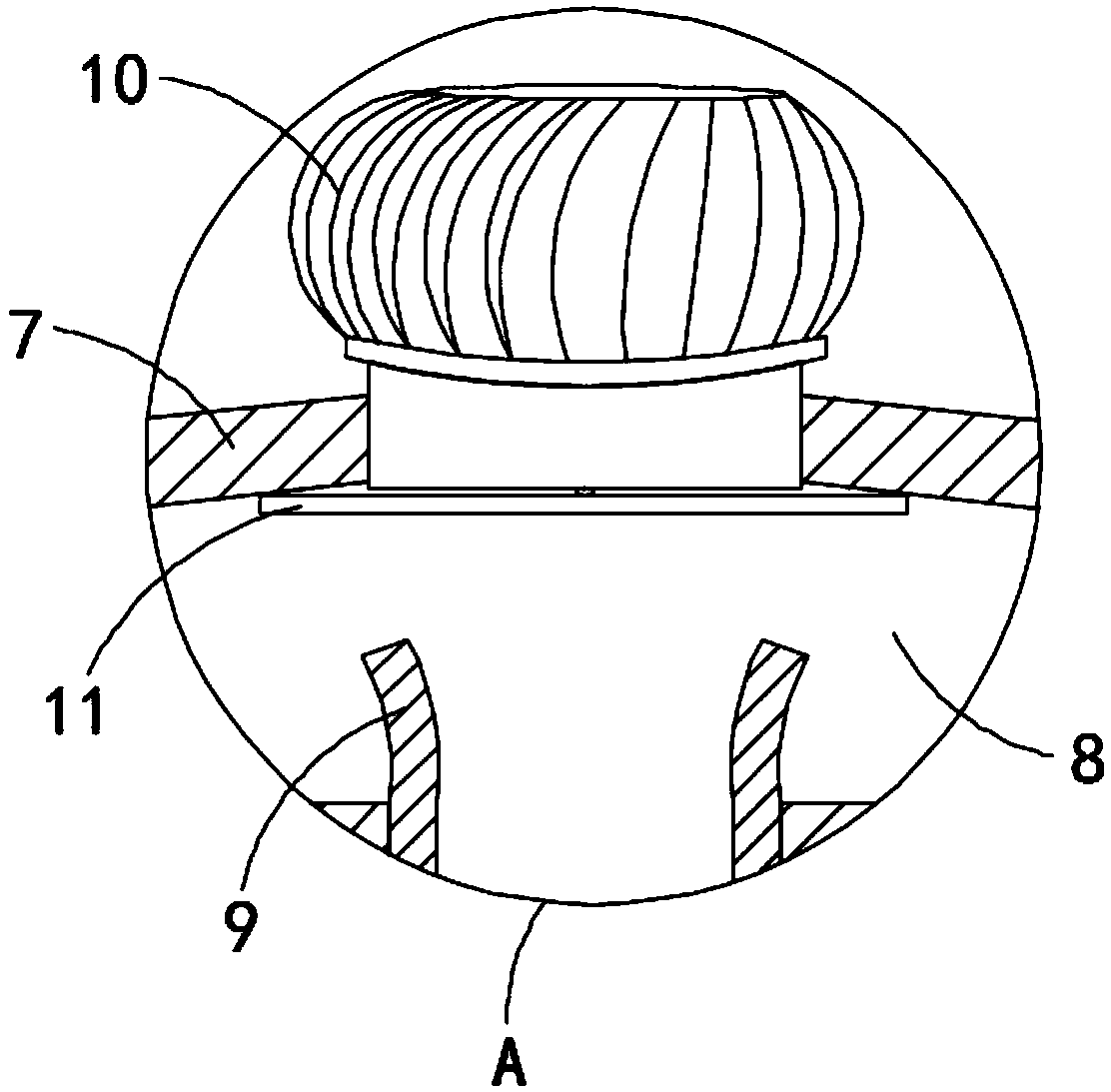

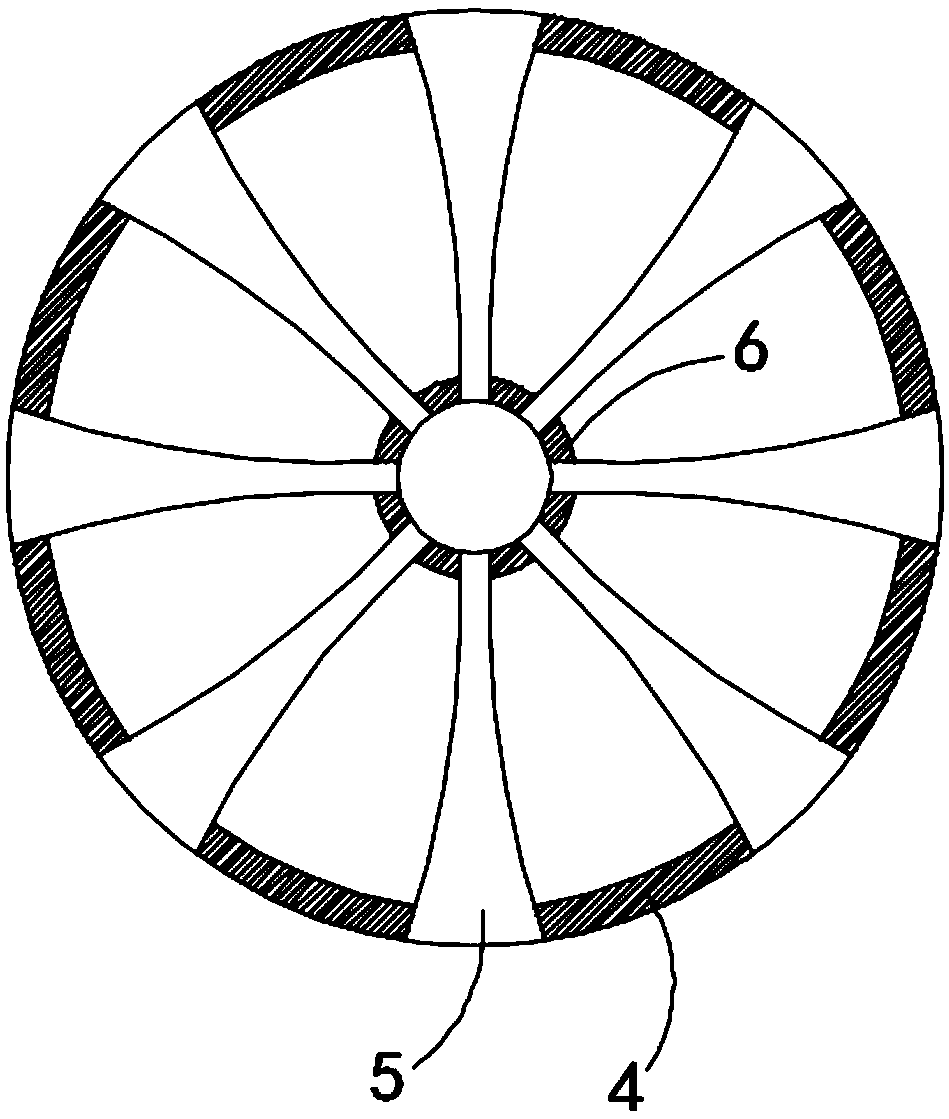

[0020] Such as Figure 1-3 As shown, a self-cleaning dust filter chimney includes a chimney body 1, an annular sealing plate 2 is fixedly connected in the chimney body 1, a cylindrical filter element 3 is fixedly connected in the annular sealing plate 2, and a ring-shaped filter element 3 is arranged in the cylindrical filter element 3. Plate 4, the side wall of the annular plate 4 is embedded with a plurality of dust suction branch pipes 5, the input end of the dust suction branch pipe 5 is in contact with the inner side wall of the cylindrical filter element 3, and the inner side wall of the cylindrical filter element 3 is slidingly sealed and connected with a dust suction pipe. Main pipe 6, the output ends of a plurality of dust suction branch pipes 5 are all connected with dust suction main pipe 6, and the output ends of dust suction branch pipes 5 are arc-shaped, and match with the side wall of annular plate 4 (such as image 3 As shown), the upper side of the chimney bod...

Embodiment 2

[0024] Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that: the lower end of the dust suction main pipe 6 is sealed and rotatably connected with a rotating pipe 12, and the output ends of a plurality of dust suction branch pipes 5 are connected to the dust suction main pipe 6 through the rotating pipe 12 Generally speaking, the dust suction branch pipe 5 is in the shape of fan blades, and the plurality of dust suction branch pipes 5 are evenly distributed around the center of the ring plate 4. It should be noted that the windward side of the wind wheel composed of a plurality of dust suction branch pipes 5 faces downward.

[0025] In this embodiment, since the plurality of dust suction branch pipes 5 are in the shape of fan blades, the smoke and dust will drive the ring plate 4 to rotate during the discharge process, thereby cleaning the cylindrical filter element 3 more comprehensively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com