Finned tube type evaporator

A technology of finned tube type and evaporator, which is applied in the direction of evaporator/condenser, heat sink, tubular element, etc., which can solve the problems of large volume of evaporator, large diameter of heat exchange tube, inconvenience, etc., and increase the heat dissipation area , small size, and the effect of reducing the cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

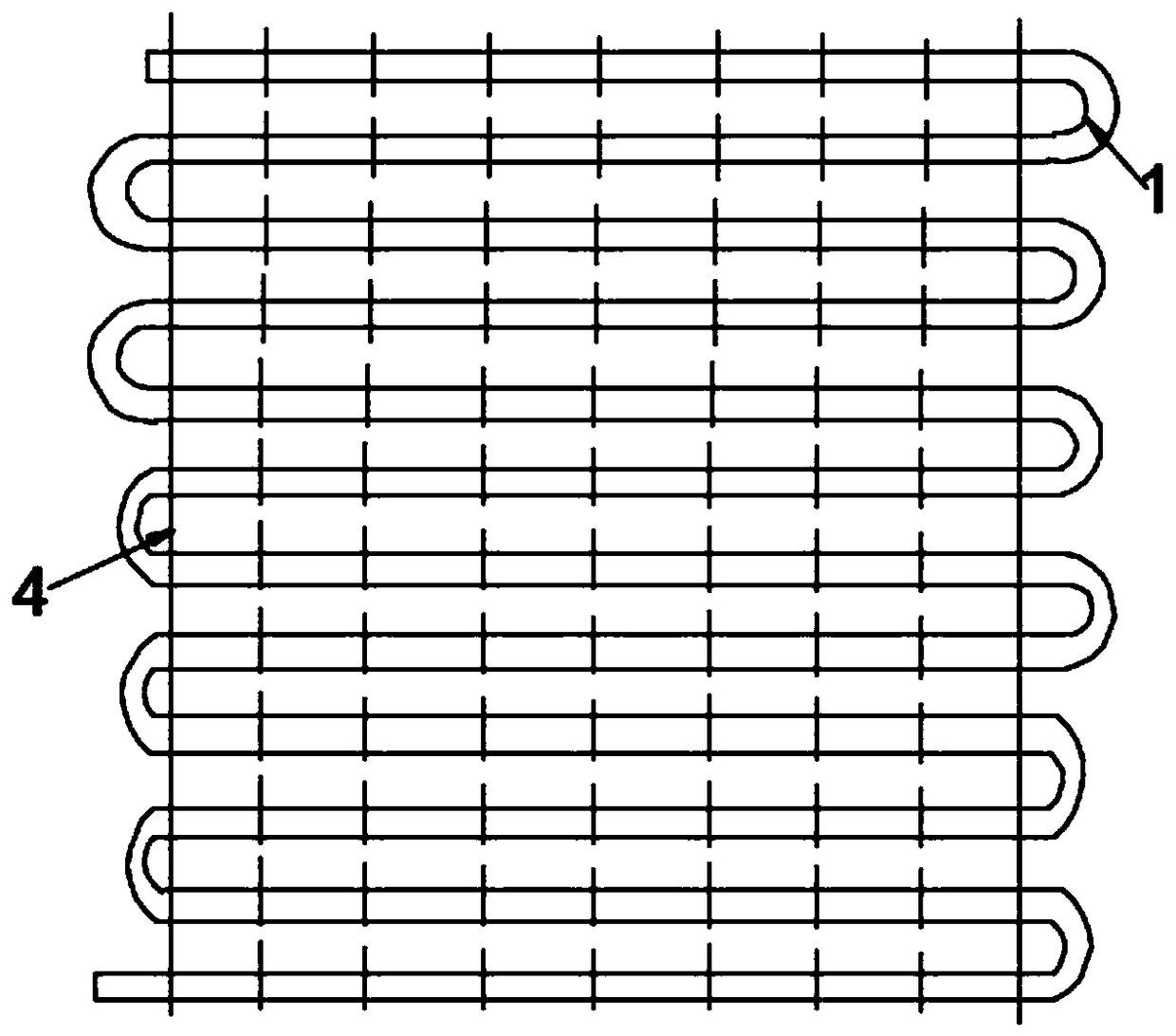

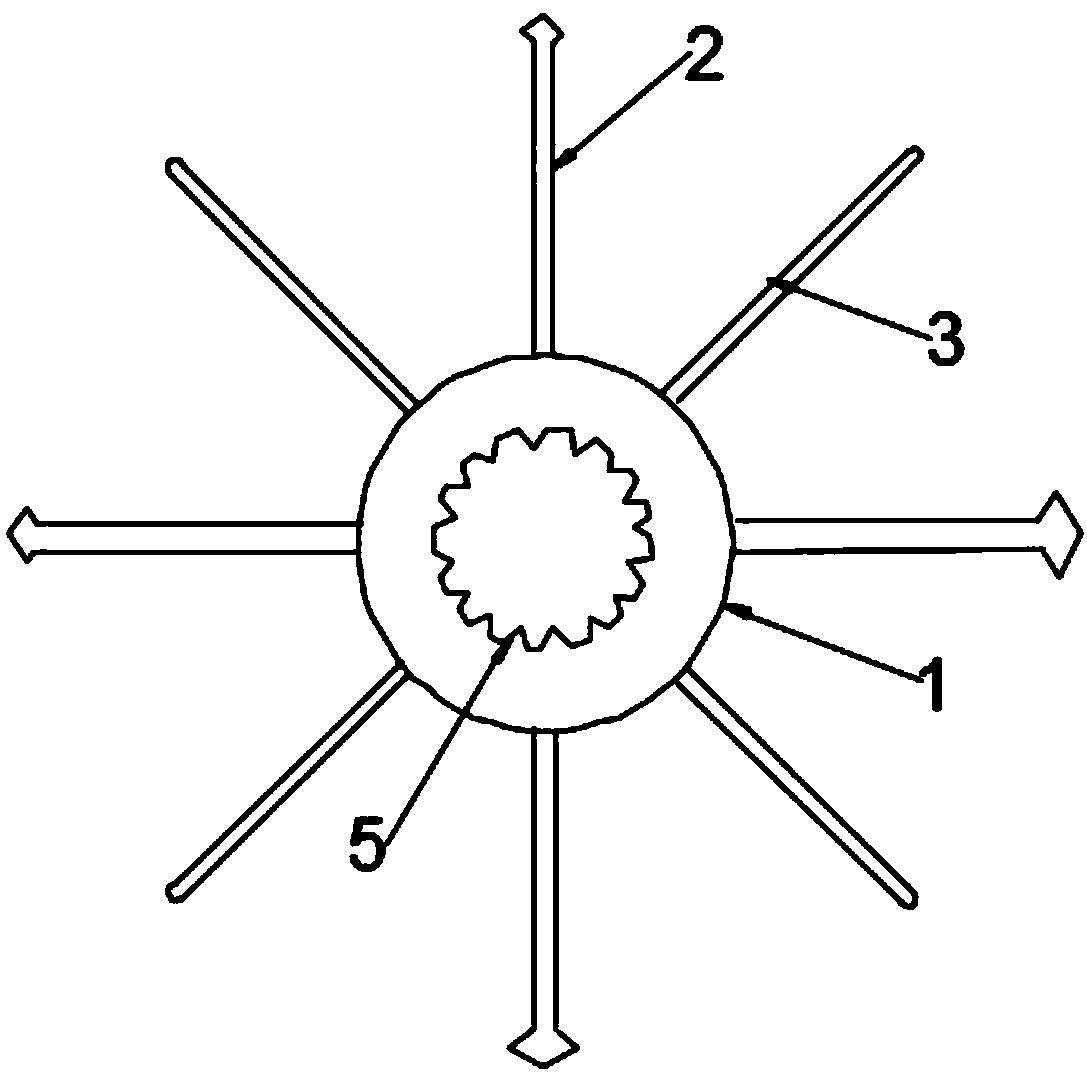

[0018] A finned tube evaporator, including a tube body 1, fins and side plates 4, the tube body 1 is formed by a tube that is bent multiple times in parallel, and the fins include first fins 2 and second fins The fins 3 and the first fins 2 and the second fins 3 are all pierced on the tube body 1. There is no fin at the bend of the tube body 1. The side plates 4 are installed at both ends of the tube body 1. The first fins 2 and the second fins 3 are uniformly arranged on the tube body 1 and the number of the first fins 2 and the second fins 3 is the same, the outer ends of the first fins 2 are diamond-shaped, and the outer ends of the second fins 3 The outer end is circular, and the inner wall of the pipe body 1 is uniformly provided with inner ribs 5, and the inner ribs 5 and the pipe body 1 are manufactured by an integral molding process. Both the first fins 2 and the second fins 3 are circular thin slices. The number of the first fins 2 is 4-8. Both the first fin 2 and t...

Embodiment 2

[0020] A finned tube evaporator, including a tube body 1, fins and side plates 4, the tube body 1 is formed by a tube that is bent multiple times in parallel, and the fins include first fins 2 and second fins The fins 3 and the first fins 2 and the second fins 3 are all pierced on the tube body 1. There is no fin at the bend of the tube body 1. The side plates 4 are installed at both ends of the tube body 1. The first fins 2 and the second fins 3 are uniformly arranged on the tube body 1 and the number of the first fins 2 and the second fins 3 is the same, the outer ends of the first fins 2 are diamond-shaped, and the outer ends of the second fins 3 The outer end is circular, and the inner wall of the pipe body 1 is uniformly provided with inner ribs 5, and the inner ribs 5 and the pipe body 1 are manufactured by an integral molding process. The length of the first fin 2 is greater than the length of the second fin 3 , and the length of the first fin 2 is 0.3-0.5 of the outer ...

Embodiment 3

[0022] A finned tube evaporator, including a tube body 1, fins and side plates 4, the tube body 1 is formed by a tube that is bent multiple times in parallel, and the fins include first fins 2 and second fins The fins 3 and the first fins 2 and the second fins 3 are all pierced on the tube body 1. There is no fin at the bend of the tube body 1. The side plates 4 are installed at both ends of the tube body 1. The first fins 2 and the second fins 3 are uniformly arranged on the tube body 1 and the number of the first fins 2 and the second fins 3 is the same, the outer ends of the first fins 2 are diamond-shaped, and the outer ends of the second fins 3 The outer end is circular, and the inner wall of the pipe body 1 is uniformly provided with inner ribs 5, and the inner ribs 5 and the pipe body 1 are manufactured by an integral molding process. Both the first fins 2 and the second fins 3 are circular thin slices. The number of the first fins 2 is 4-8. The length of the first fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com