Cotton and linen cloth drying equipment

A cloth drying, cotton linen technology, applied in the direction of drying, dryers, lighting and heating equipment, etc., can solve the problems of large space occupied by equipment, affect the dyeing effect of fabrics, and reduce the drying efficiency of equipment. The space is small, the effect of improving heat transfer, and the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

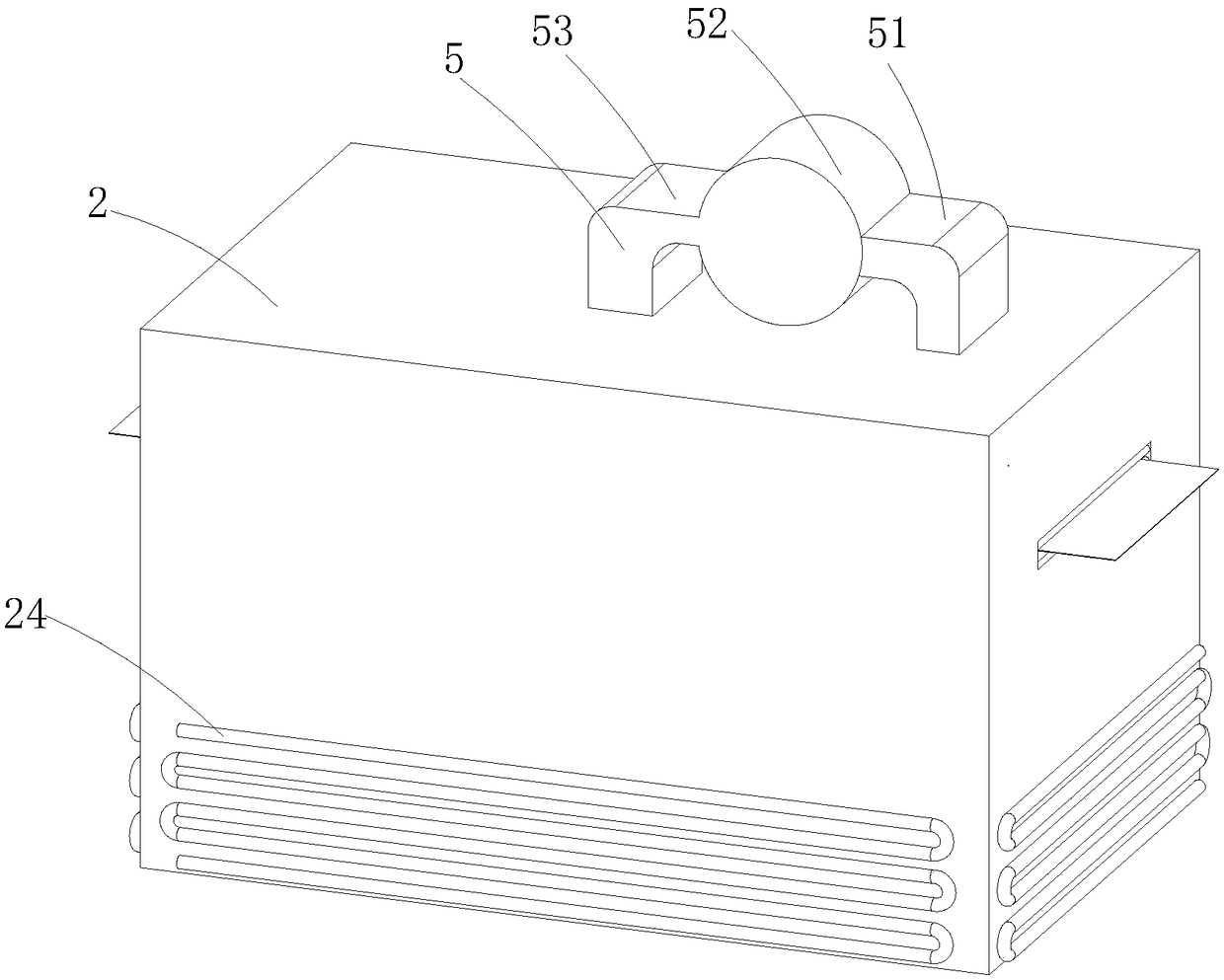

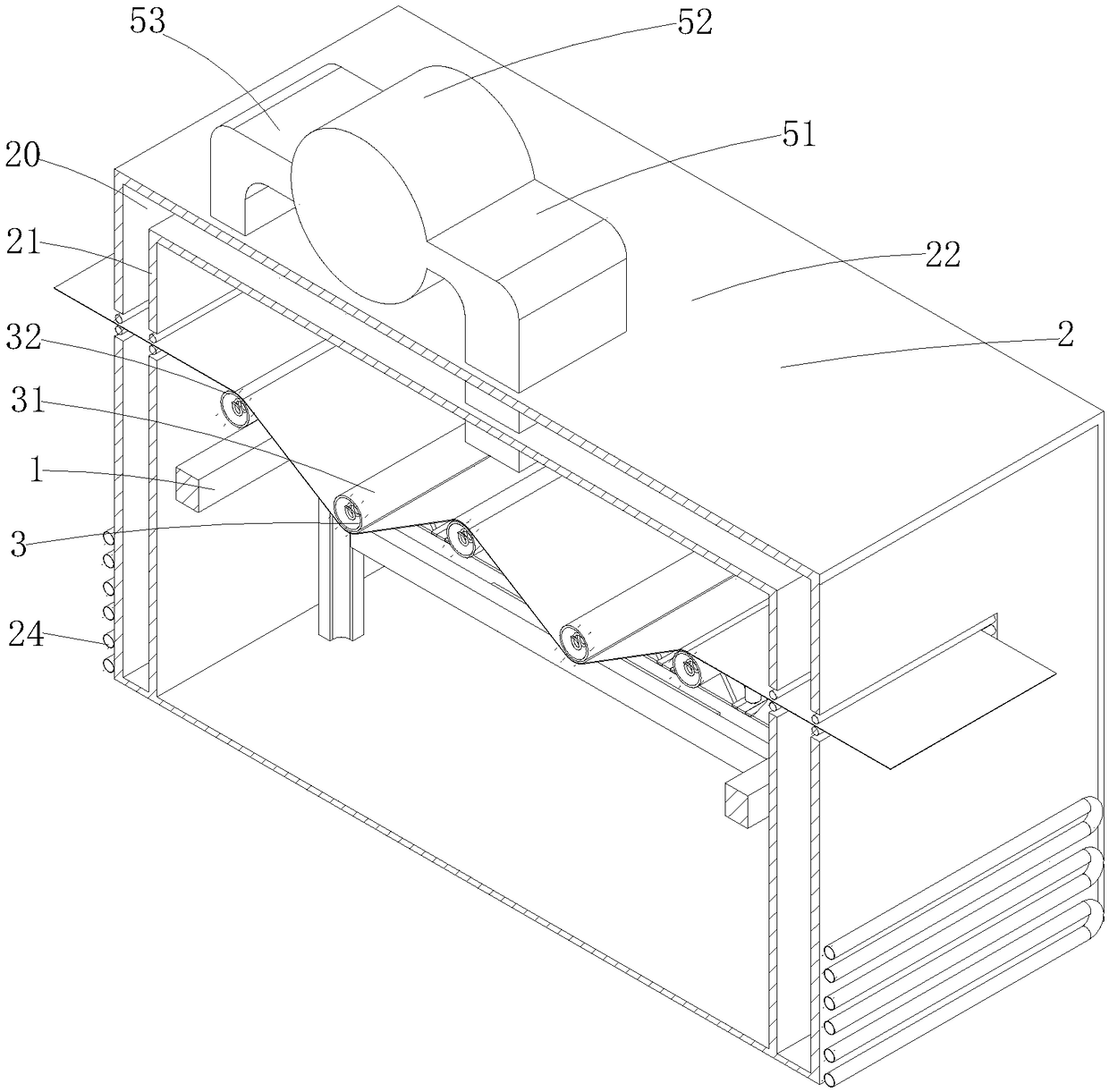

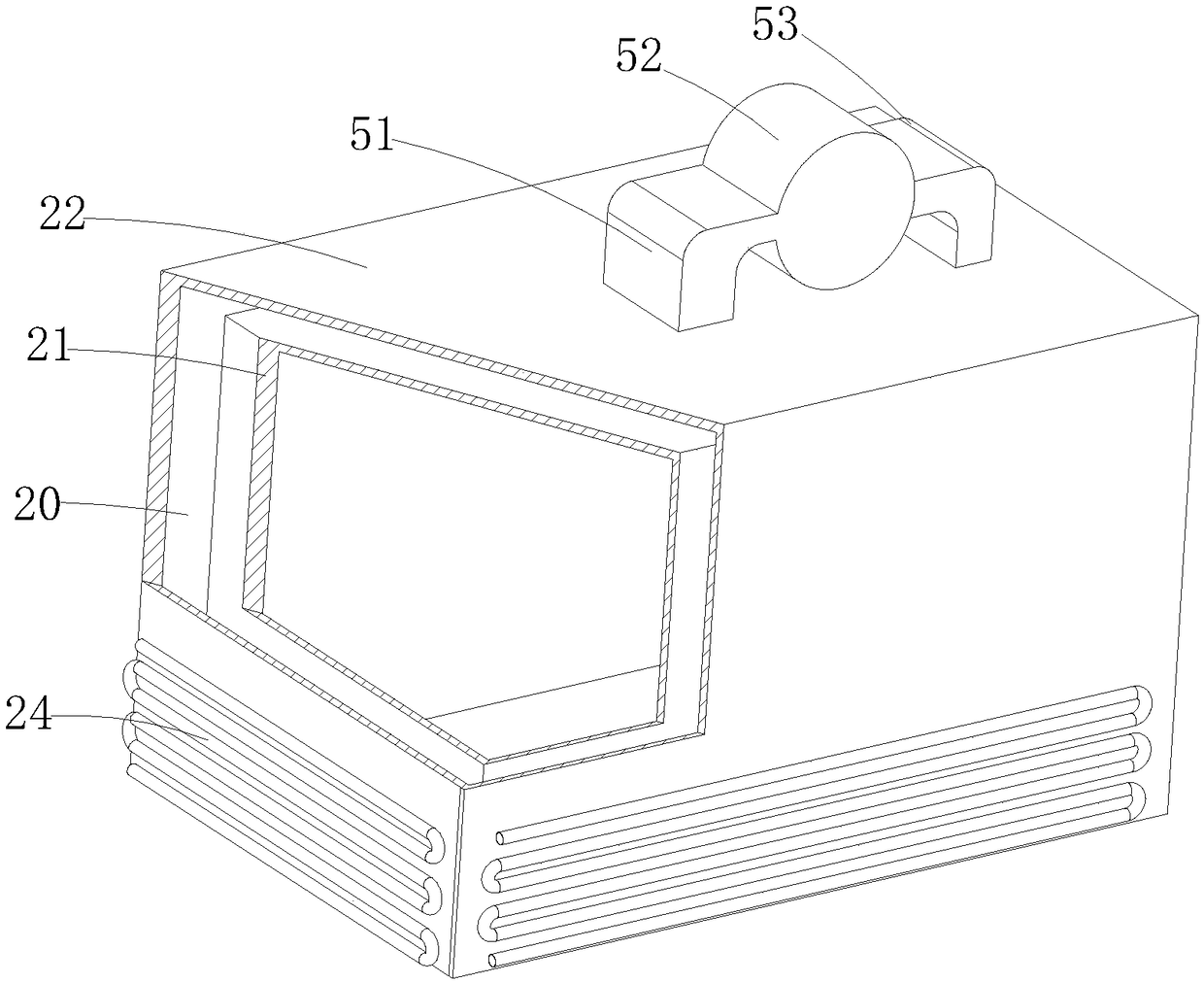

[0041] Such as Figure 1-18 As shown, a cotton and linen drying equipment, a frame 1, a box body 2, a drying roller structure 3, a heating structure 4 and a dehumidification structure 5, wherein the frame 1 is a metal frame, and the box body 2 Covered in the frame 1, the drying roller structure 3 is arranged on the frame 1, the drying roller structure 3 is used to be in contact with the cotton and linen cloth, and will dry the clothes Stretch the cloth to increase the holes on the cloth. Specifically, the drying roller structure 3 includes a plurality of first roller bodies 31, a plurality of second roller bodies 32 and a driving part 33; specifically, the The first roller b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com