Quadrangular-pyramid-shaped material layer loosening filler

A loosening and four-corner technology, which is applied in the field of four-corner loosening material layer packing, can solve the problems that the waste heat recovery shaft furnace cannot operate normally, the air supply system cannot provide the circulating air volume, and the high gas flow resistance, etc., and achieves uniform and efficient cooling process. , The effect of reducing energy consumption and reducing gas flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be further described below:

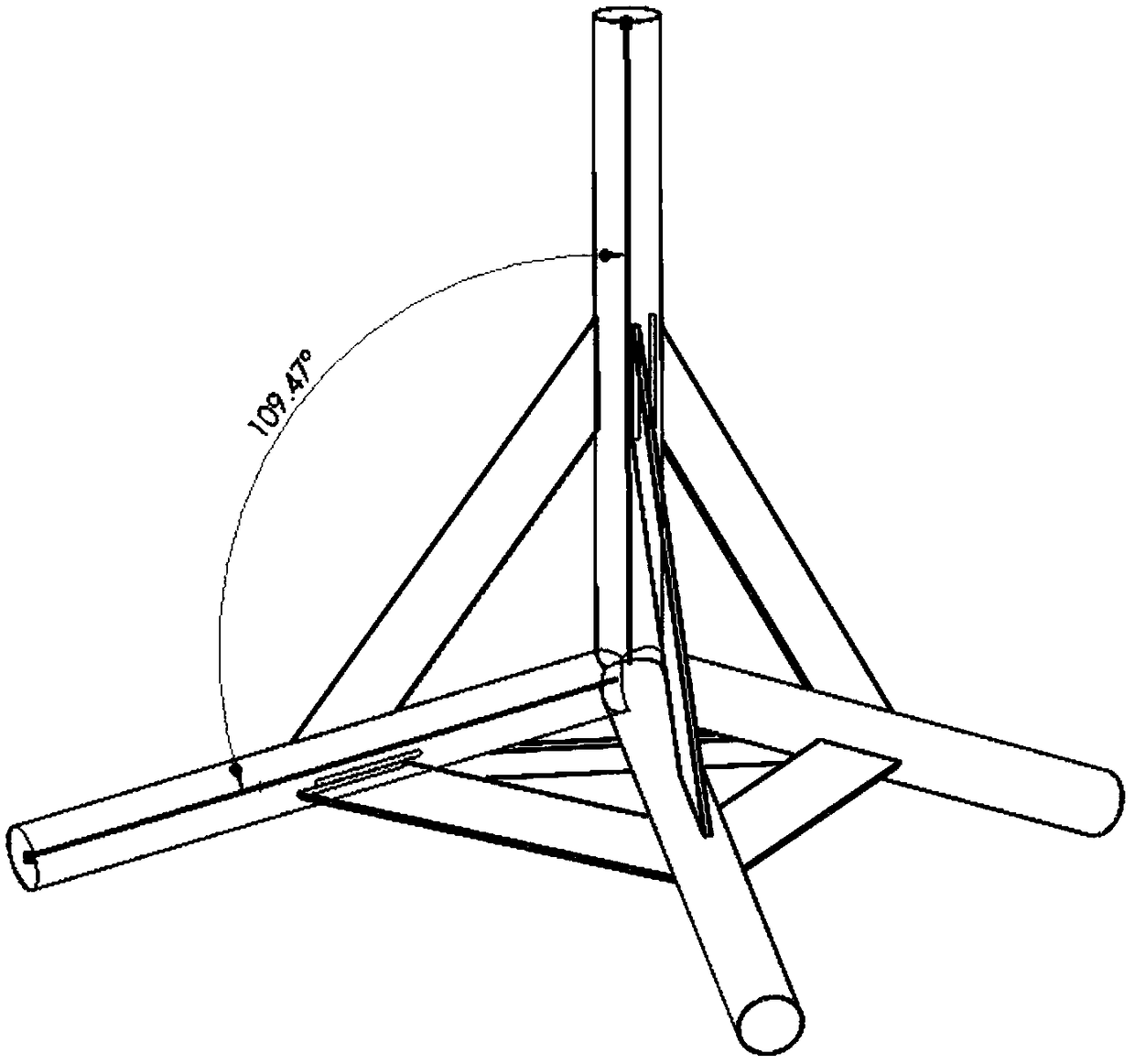

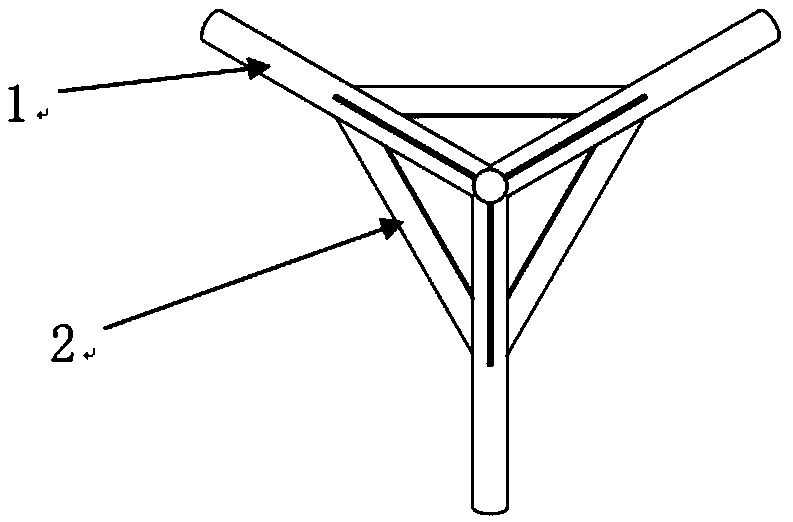

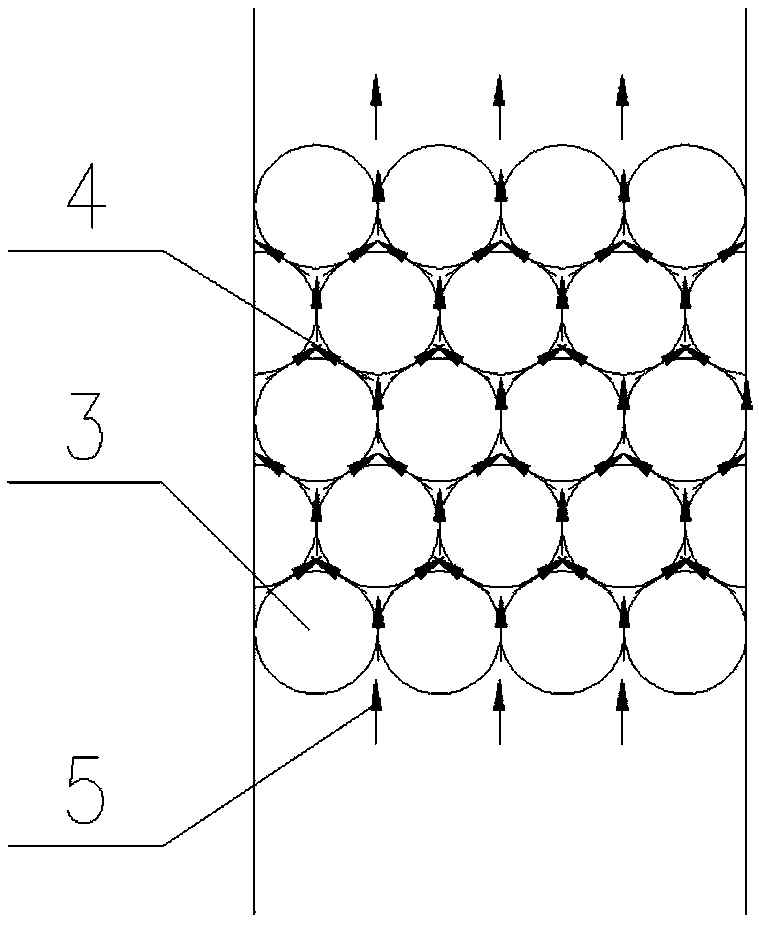

[0019] Such as Figure 1-4 As shown, a tetragonal loose material layer packing includes a supporting column 1 and a reinforcing plate 2. Four supporting columns 1 are connected and fixed at the same end point, and the angle between two adjacent supporting columns 1 is 109.47°, any The two supporting columns 1 are connected and fixed by a reinforcing plate 2. When in use, the filler is evenly distributed in the solid particles of high-temperature materials recovered by gas-solid contact waste heat.

[0020] The four support columns 1 have the same specifications and dimensions.

[0021] The supporting column 1 is a cylinder or a prism.

[0022] There are six reinforcing plates 2 and the six reinforcing plates have the same specifications and dimensions. One reinforcing plate 2 is fixed between every two supporting columns 1, and the supporting column 1 and the reinforcing plate 2 form an iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com