Pyramid loosening material filler

A cone and loosening technology, applied in the field of waste heat recovery of solid materials, can solve the problems such as the inability of the air supply system to provide the circulating air volume, the failure of the waste heat recovery shaft furnace to operate normally, and the high gas flow resistance, etc., and achieve easy mass production and maintenance. The effect of maintenance and cooling process is uniform and efficient, and the effect of reducing gas flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

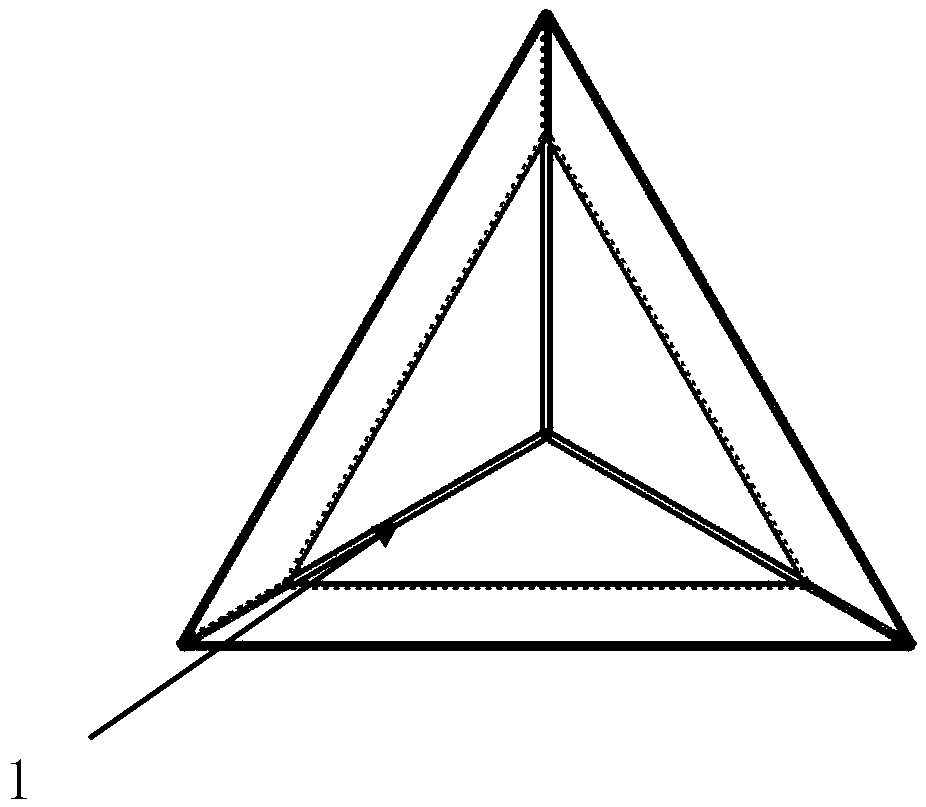

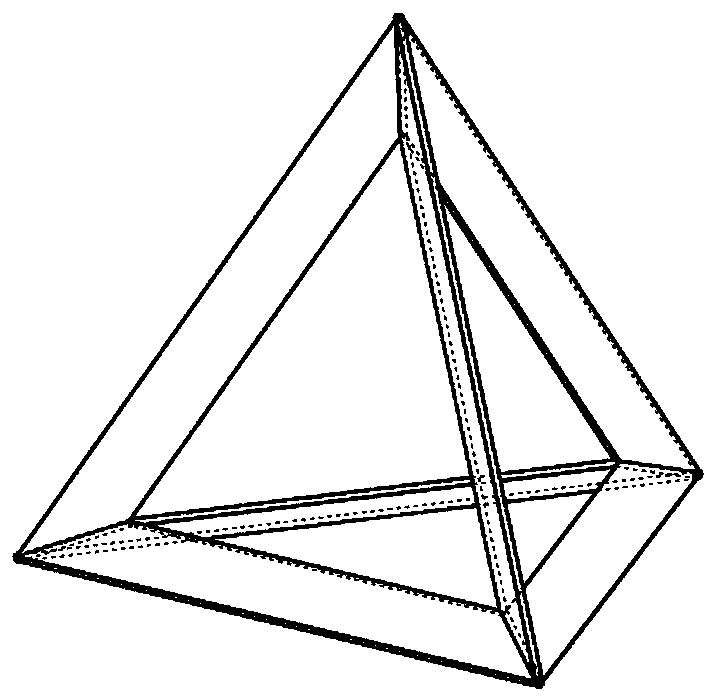

[0018] Such as Figure 1-4 As shown, a pyramidal loosening material layer filler, the pyramid is a triangular pyramid with a total of four vertices, consisting of 6 support beams 1 of the same size, and each vertex has three support beams 1 end points Fixed and connected; the filler is evenly distributed in the high-temperature material solid particles recovered from gas-solid contact waste heat.

[0019] The supporting beam 1 is in the shape of a column, a slat or an arc plate.

[0020] The material of the support beam 1 is steel, iron or iron alloy. The support beam 1 has good thermal conductivity and high mechanical properties.

[0021] The length of the supporting beam 1 is 10-200mm.

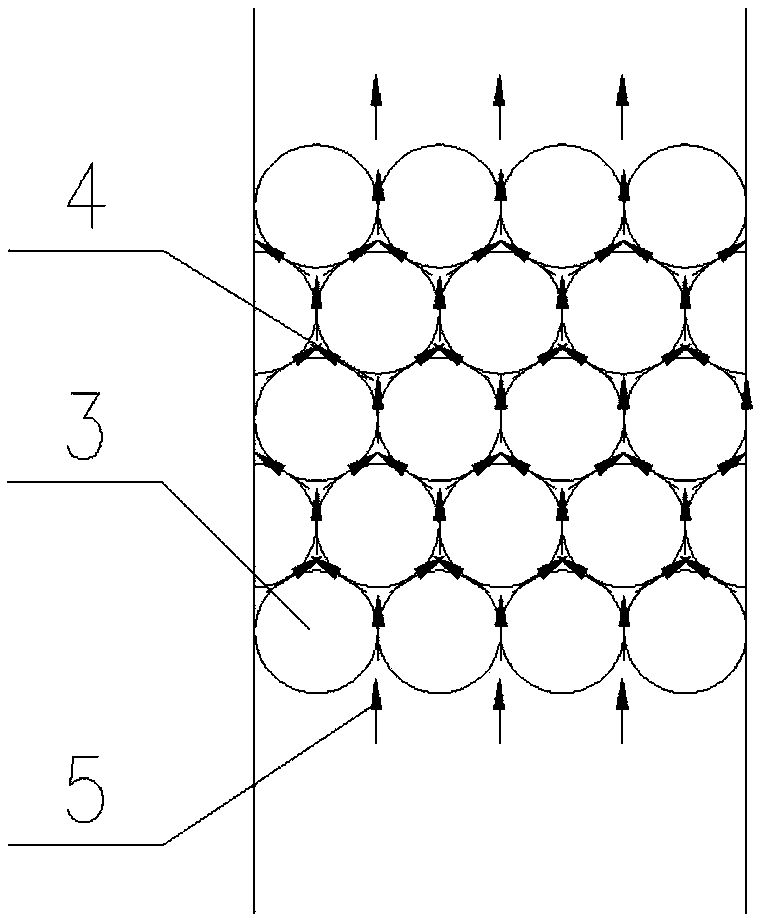

[0022] A method for using a pyramid loosening material layer filler, the pyramid loosening material layer filler 2 is uniformly mixed in the high temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com