Method for preparing liquid suction core in pressure sintering method

A pressurized sintering and liquid-absorbing core technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of uneven porosity and shrinkage during sintering, and achieve the goal of improving the uniformity of porosity and avoiding shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The metal tube shell is made of 18*3 metal titanium tube; the metal layer (1) is made of porous stainless steel with a pore diameter of

[0022] 13μm, the porosity is 65%. The metal powder is nickel powder with a particle size of 2 μm.

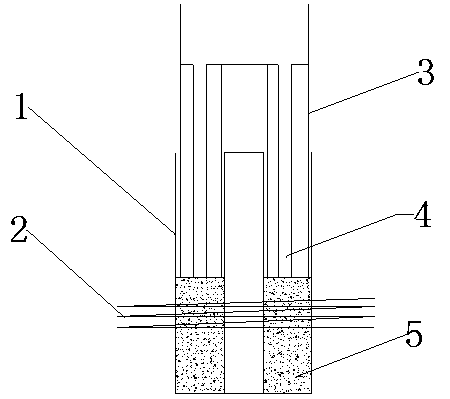

[0023] Such as figure 1 As shown, the porous stainless steel is inserted into the titanium tube with the lower end fixed. Nickel powder from the feeding device

[0024] Pour from above, set the motion period of the feeding device to 1 s, the pressing pressure of the feeding device on the metal powder is 2 MPa, and the frequency of the induction coil is 1000 HZ.

[0025] The moving speed of the titanium tube is 0.2 cm / s. To be sintered with nickel powder between the titanium tube and the porous stainless steel

[0026] After the liquid-absorbent core, stop each equipment, and the preparation of the liquid-absorbent core can be completed.

Embodiment 2

[0028] 22*3 metal copper pipes are selected for the metal shell; porous stainless steel is selected for the metal layer (1), and the aperture is

[0029] 20μm, the porosity is 55%. The metal powder is nickel powder with a particle size of 5 μm.

[0030] Such as figure 1 As shown, the porous stainless steel is inserted into the copper tube, and the lower end is fixed. Nickel powder from the feeding device

[0031] Pour from above, set the motion cycle of the feeding device to 2 s, the pressing pressure of the feeding device on the metal powder is 3 MPa, and the frequency of the induction coil is 2000 HZ.

[0032] The moving speed of the titanium tube is 0.1 cm / s. After the copper tube and the porous stainless steel are filled with copper powder and sintered

[0033] After the liquid-absorbent core, stop each equipment, and the preparation of the liquid-absorbent core can be completed.

Embodiment 3

[0035] The metal tube shell is made of 16*1 metal copper tube; the metal layer (1) is made of porous copper, and the aperture is

[0036] 15μm, the porosity is 55%. The metal powder is copper powder with a particle size of 1 μm.

[0037] Such as figure 1 As shown, the porous copper is inserted into the copper pipe, and the lower end is fixed. Copper powder from the feeding device

[0038] Pour from above, set the motion period of the feeding device to 3 s, the pressing pressure of the feeding device on the metal powder is 1 MPa, and the frequency of the induction coil is 1500 HZ.

[0039] The moving speed of the titanium tube is 0.4 cm / s. The suction liquid that is filled with copper powder and sintered between the copper tube and the porous copper

[0040] After the core is finished, all equipment is stopped to complete the preparation of the liquid-absorbent core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com