Pre-alloyed high-entropy alloy porous material and preparation method thereof

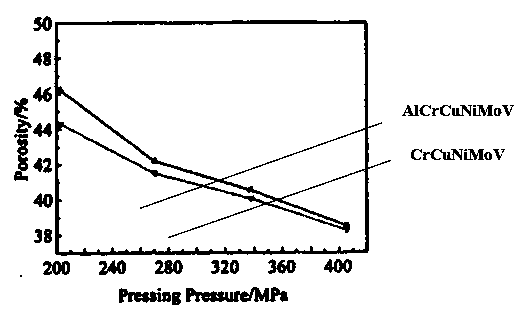

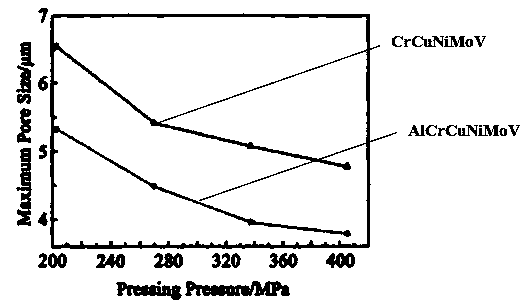

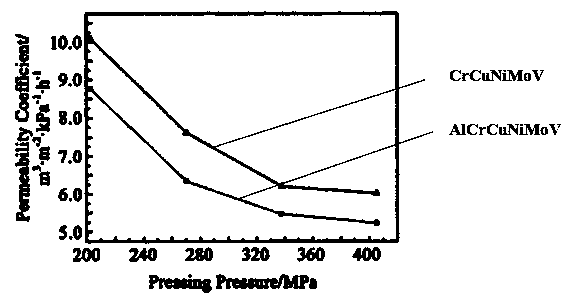

A pre-alloying, high-entropy alloying technology, applied in the field of alloy material preparation, can solve the problems of uneven interconnected pores, excessive size, corrosion resistance and weak shear strength of porous materials, and achieve rich pores and uniform pore size distribution. , Excellent effect of high temperature resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0035] A pre-alloyed CrCuNiMoV high-entropy alloy porous material. In this embodiment, the composition of the pre-alloyed high-entropy alloy porous material is CrCuNiMoV, and the molar ratio of Cr:Cu:Ni:Mo:V is: 1: 1:1:1:1.

[0036] The specific preparation process of the above-mentioned pre-alloyed CrCuNiMoV high-entropy alloy porous material is as follows:

[0037] The first step, raw material weighing: Weigh ultrasonically treated Cr material, Cu material, Ni material, Mo material, V material according to equimolar ratio; the forms of Cu, Cr, Ni, Mo and V materials are all except powder flakes, lumps or large granules, and their respective purity ≥ 99.5%.

[0038] The second step is atomization powder making...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com