Novel component test fixture

A technology for testing fixtures and components, which is applied to parts, instruments, and measuring electronics of electrical measuring instruments. It can solve problems such as unstable quality, low efficiency, and design quality depending on personal experience and habits, and achieve wide versatility. The effect of accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

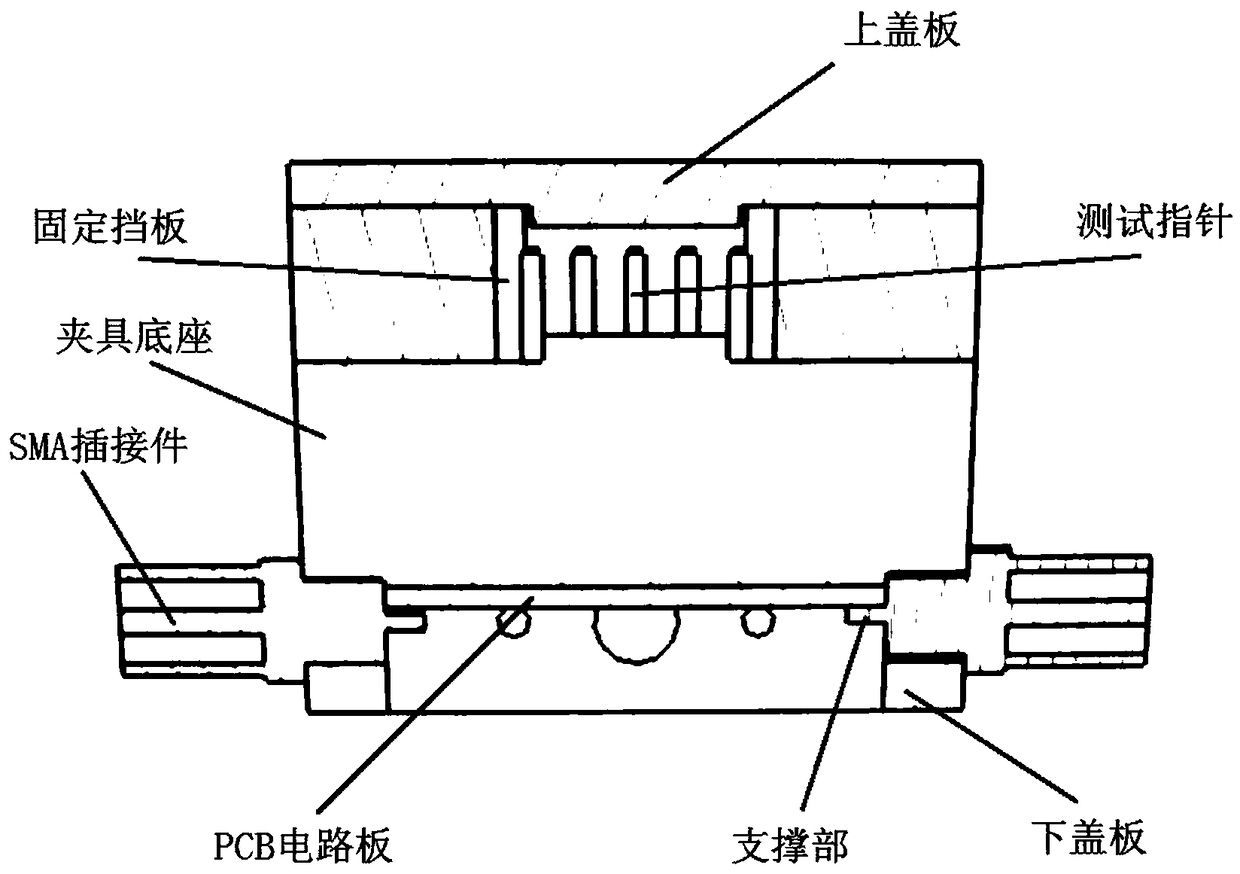

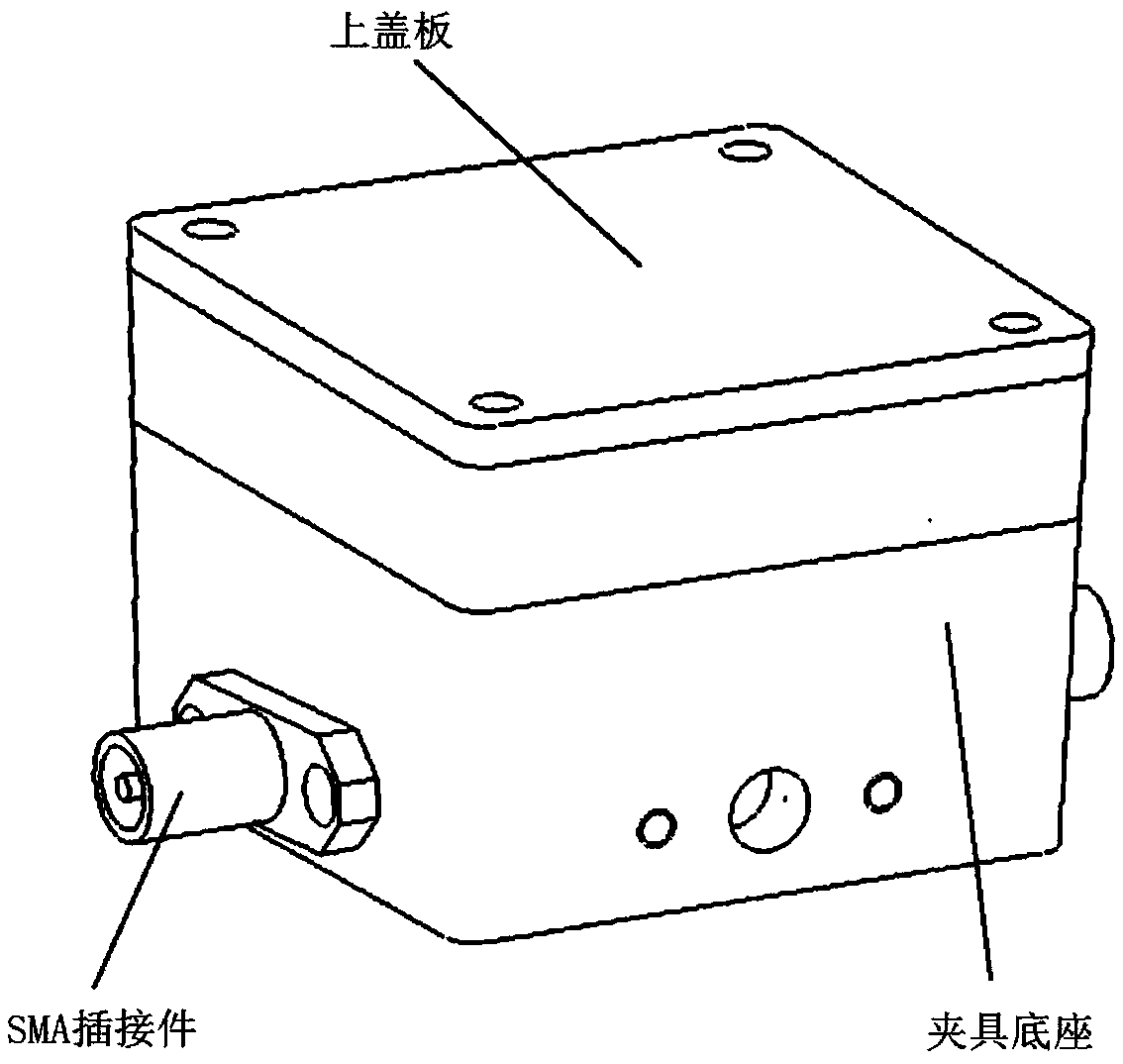

[0020] Such as figure 1 , 2 As shown, a new type of component test fixture specifically includes a fixture base, a fixed baffle, a test probe, a PCB circuit board, an upper cover, a lower cover and an SMA connector. The fixture base is an upper surface, a lower Tetrahedral structure hollowed out on the surface and inside; the SMA connector is fixed on the side wall of the fixture base and passes through the side wall of the fixture base; the part of the SMA connector passing through the side wall has a support portion, so A PCB circuit board is installed above the support portion; a test pointer is welded on the PCB circuit board, and the test pointer is vertically arranged, and the top of the test pointer is a device under test placement area; the fixed baffle is arranged on the device under test Around the placement area, the fixed baffle is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com