Hot pot stove

A technology for a fire boiler and a furnace body, applied in the field of fire boilers, can solve the problems of no filter screen, damage to the dining environment, no setting, etc., and achieve the effects of maintaining the taste, avoiding the accidental consumption of seasonings, and maintaining the dining environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

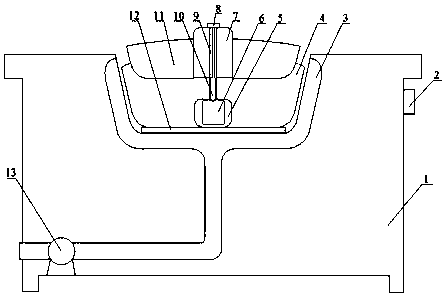

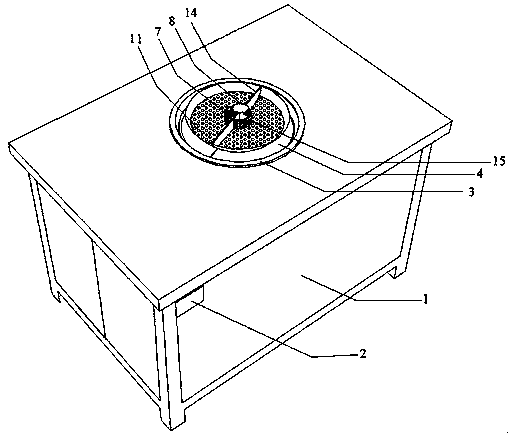

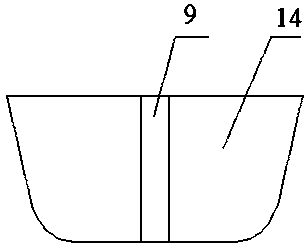

[0020] Such as figure 1 , 2 , 3, and 4, a fire boiler according to the present invention includes a body of furnace 1, a temperature-controlled induction cooker 12 arranged at the center of the upper part of the furnace body, and a soup pot 4 placed on the temperature-controlled induction cooker 12, and one side outside the body of furnace 1 A controller 2 is provided, and the controller 2 is connected to the temperature-controlled induction cooker 12, the induced draft fan 13 and the motor 6 for control through wires; the furnace body 1 is provided with an exhaust cavity 3, and the exhaust cavity 3 is located in the soup pot 4 Periphery, and is connected with the induced draft fan 13 of body of heater 1 bottom by pipeline; On the central axis of soup pot 4 bottoms, seal is connected with the sealing cover 5 of convex shape, and motor 6 is installed in the middle of this sealing cover 5, and its top is fixed with Partition plate 14, and the central position of this partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com