Oil spraying device of feed mixing machine

A technology of oil spraying device and mixing device, which is applied in the direction of mixer, feed, mixer with rotating stirring device, etc. It can solve the problems of not much oil mist, feed not absorbed, oil mist can not be completely absorbed, etc., to ensure Safety, avoidance of uneven distribution, effect of avoiding fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

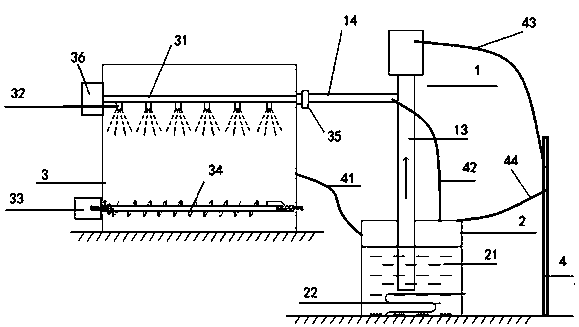

[0025] Combine below Figure 1 to Figure 2 , the present invention is further described:

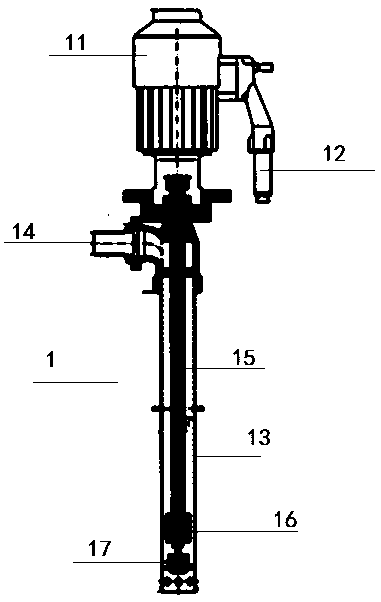

[0026] Such as figure 1 As shown, the fuel injection device 1 in the present invention comprises an explosion-proof motor 11, an oil inlet pipe 13, an oil outlet pipe 14, a rotating shaft 15 and blades 17, the oil inlet pipe 13 is vertically arranged, and the explosion-proof motor 11 is installed on the top of the oil inlet pipe 13 and passes through the rotating shaft 15 Connected with the vane 17, the rotating shaft 15 and the vane 17 are located in the oil inlet pipe 13; the oil outlet pipe 14 is connected to the wall of the oil inlet pipe 13 and the two communicate.

[0027] A sleeve 16 is provided between the oil inlet pipe 13 and the rotating shaft 15 to axially locate the rotating shaft 15 .

[0028] One end of the oil inlet pipe 13 is an axial opening, and the oil inlet pipe 13 is connected with the explosion-proof motor 11 through the axial opening, and the other end of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com