Method and equipment for conveying and fixing workpiece

A workpiece and equipment technology, applied in the corresponding equipment field, can solve the problems of high investment and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

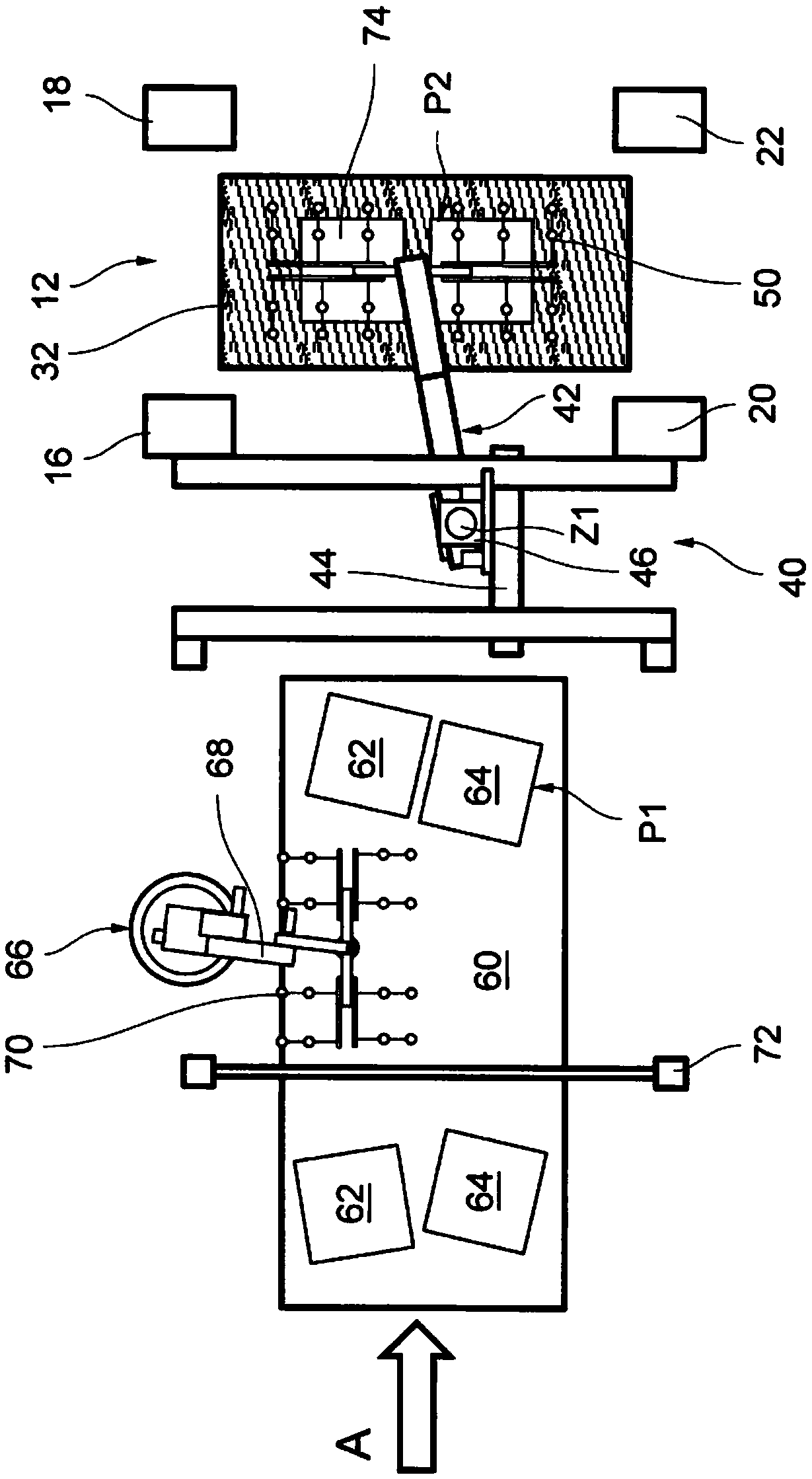

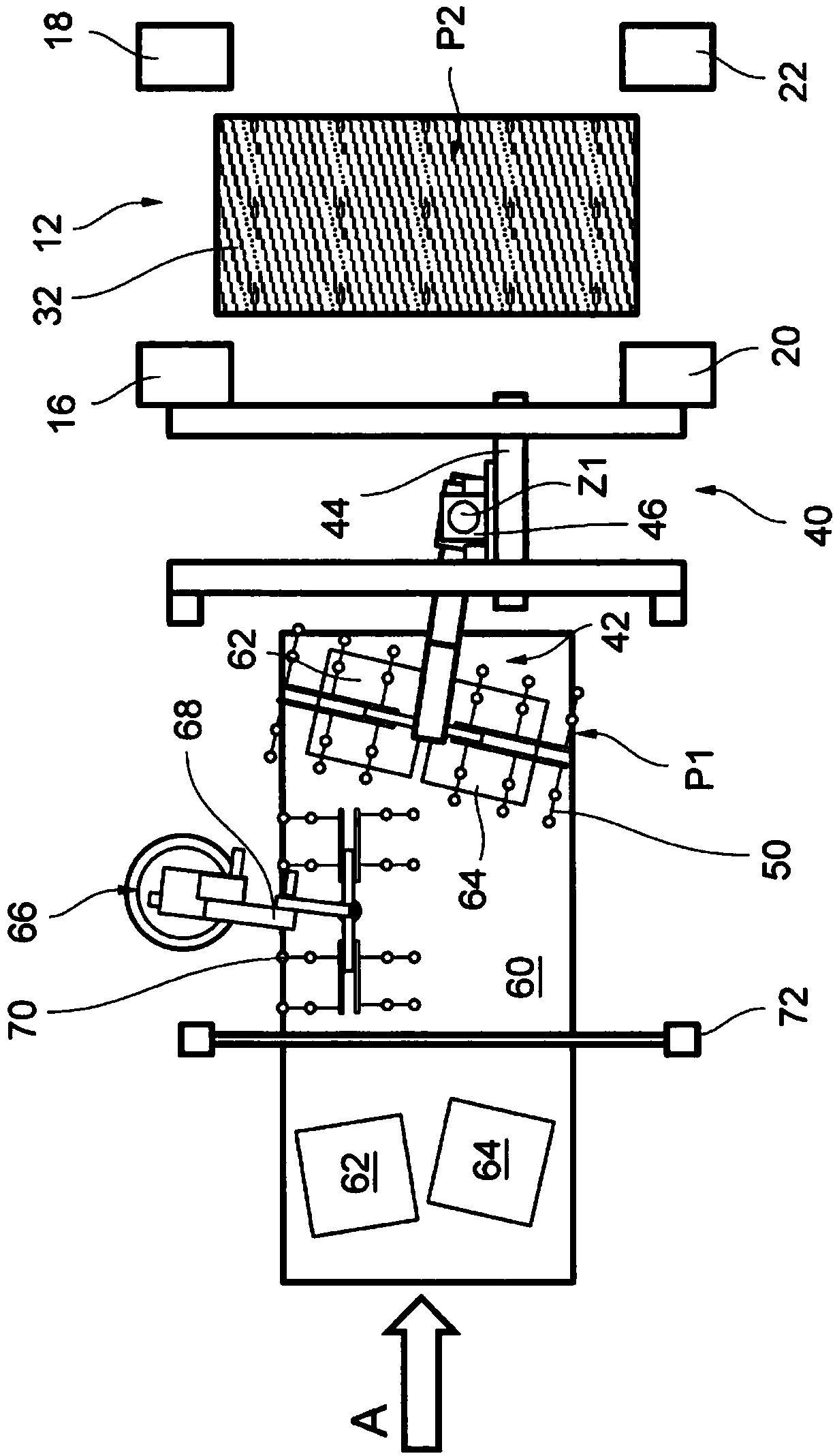

[0023] figure 1 It shows a top view of the starting area of a press line, which includes a press 12 with four press supports 16, 18, 20, 22 and a bottom tool 32 arranged therein. The workpiece is punched between the bottom tool 32 and the top tool not shown and located thereon. To load the press 12, a transfer tool 40 is used, which receives the workpiece from a continuous conveyor, here a conveyor belt 60, and moves along the flow direction A (in figure 1 (Marked by an arrow) into the press 12 and placed there. For this purpose, the conveyor belt 60 transports the workpieces in the flow direction A into an area, whereby a plurality of workpieces can be simultaneously received by the transfer tool 40 from the receiving position P1 and transferred to the placement position on the bottom tool 32 of the press 12 P2. In the embodiment shown, the transfer tool 40 picks up and transfers the two workpieces 62, 64 accordingly. In addition, in figure 1 Also shown is a pair of workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com