Method and device for conveying and positioning workpieces

A workpiece and equipment technology, applied in the corresponding equipment field, can solve the problems of high cost and high investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

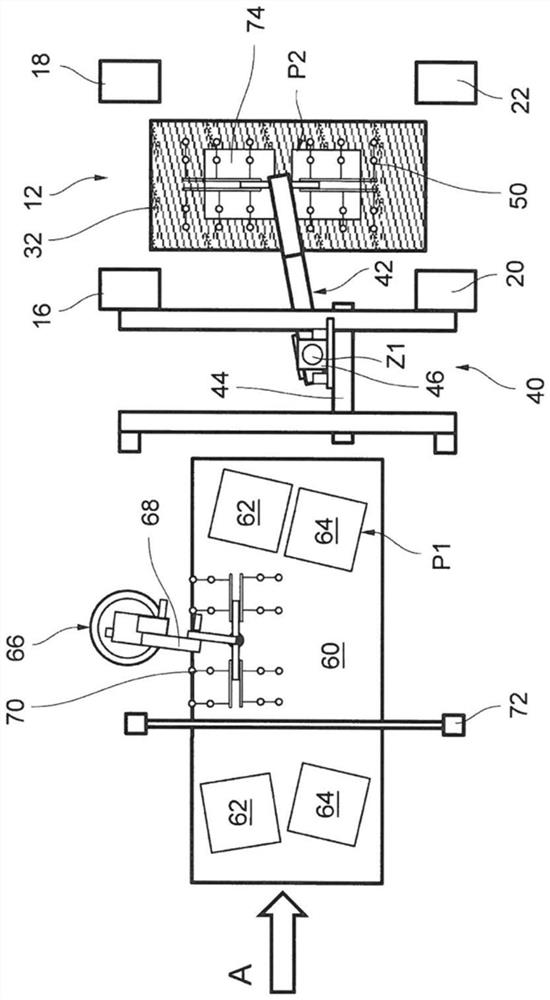

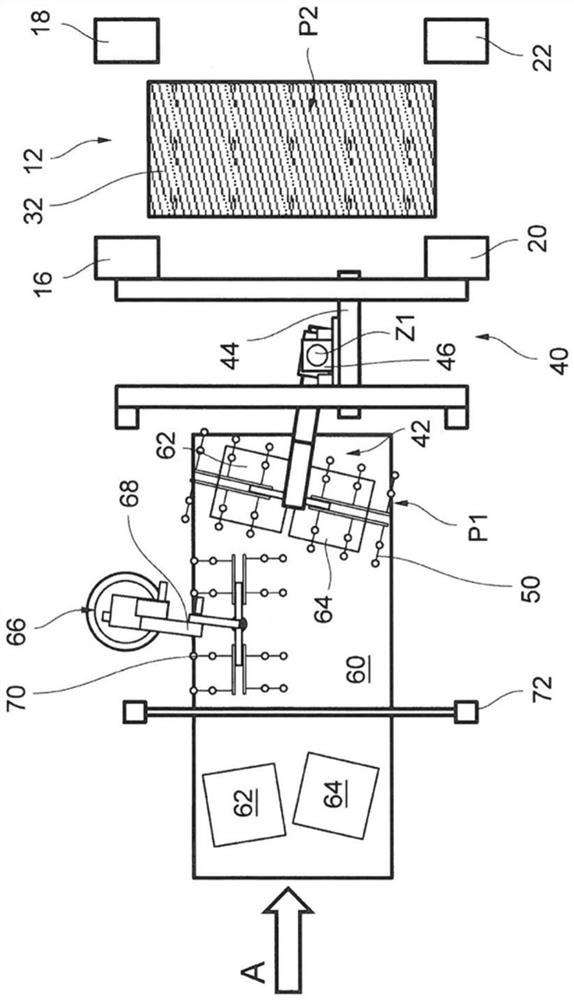

[0023] figure 1 A top view of the starting area of a press line comprising a press 12 with four press supports 16 , 18 , 20 , 22 and a bottom tool 32 arranged therein is shown from above. The workpiece is punched between this bottom tool 32 and a top tool (not shown) lying thereon. To load the press 12, a transfer tool 40 is used, which receives the workpieces from a continuous conveyor, here a conveyor belt 60, and along the flow direction A (in figure 1 marked by arrows) into the press 12 and placed there. For this purpose, the conveyor belt 60 transports the workpieces along the flow direction A into an area whereby a plurality of workpieces can be simultaneously received by the transfer tool 40 from the receiving position P1 and transferred to a placement position on the bottom tool 32 of the press 12 P2. In the embodiment shown, the two workpieces 62 , 64 are respectively picked up and transferred by the transfer tool 40 . In addition, in figure 1 Also shown in is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com