Method for bushing repairing of thread hole

A technology of threaded holes and inserts, which is applied in the field of mechanical parts repair and treatment, to achieve the effects of preventing misalignment, improving integrity and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for repairing threaded blind holes with inserts, comprising the steps of:

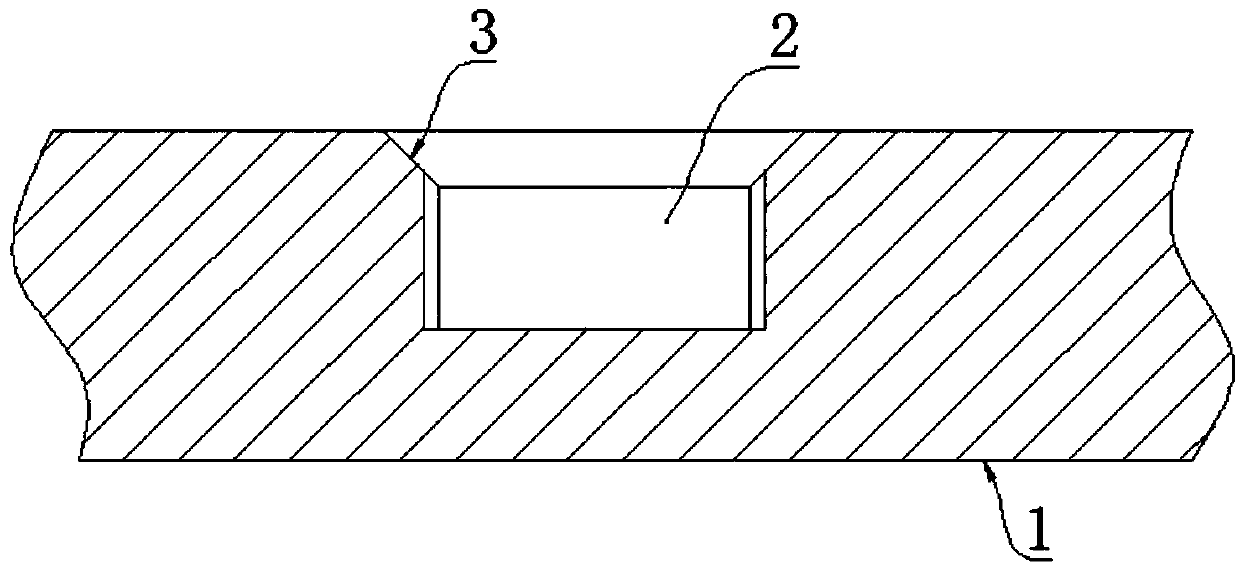

[0041] S1. Reaming and eliminating defects: expand the threaded hole A2 to be repaired to the pre-designed insert size, eliminate the defective part, and spot-face a 30° chamfer 3 on the top edge of the threaded hole A2;

[0042] S2. Preparation of filling parts: select the same or similar material as the base metal 1, and turn out bolts suitable for the threaded hole A2;

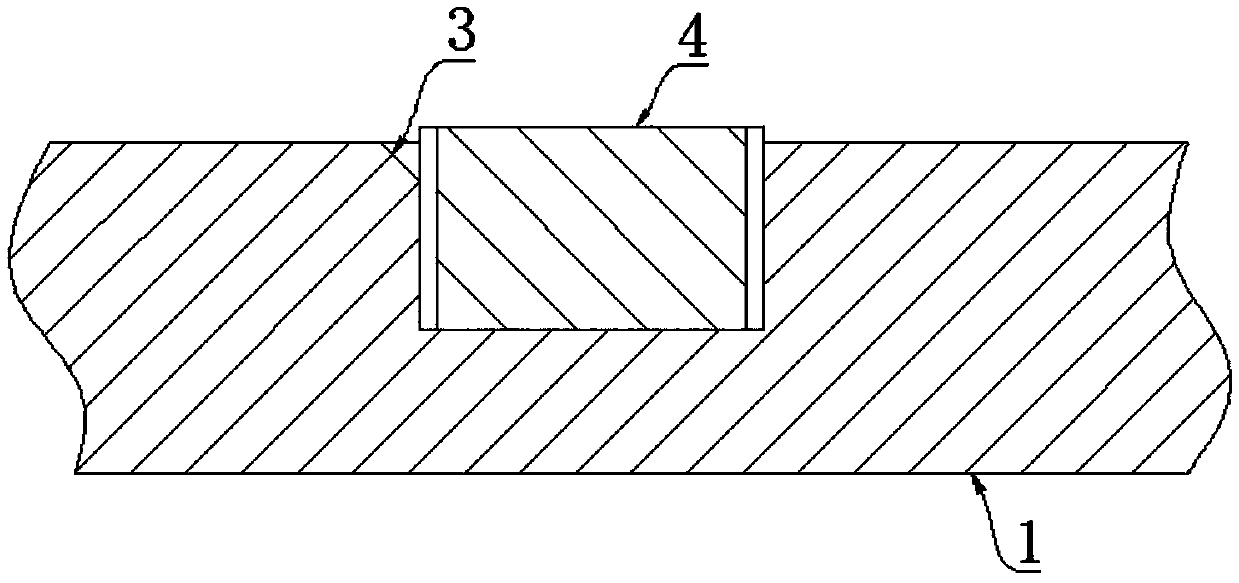

[0043] S3. Filling the threaded hole: apply high-strength thread-locking glue on the periphery of the bolt, and then assemble it into the threaded hole A2;

[0044] S4. Welding: Weld the bolt at the chamfer 3 according to the welding parameters, and weld the chamfer 3 to the full, and control the welding deformation during the welding process;

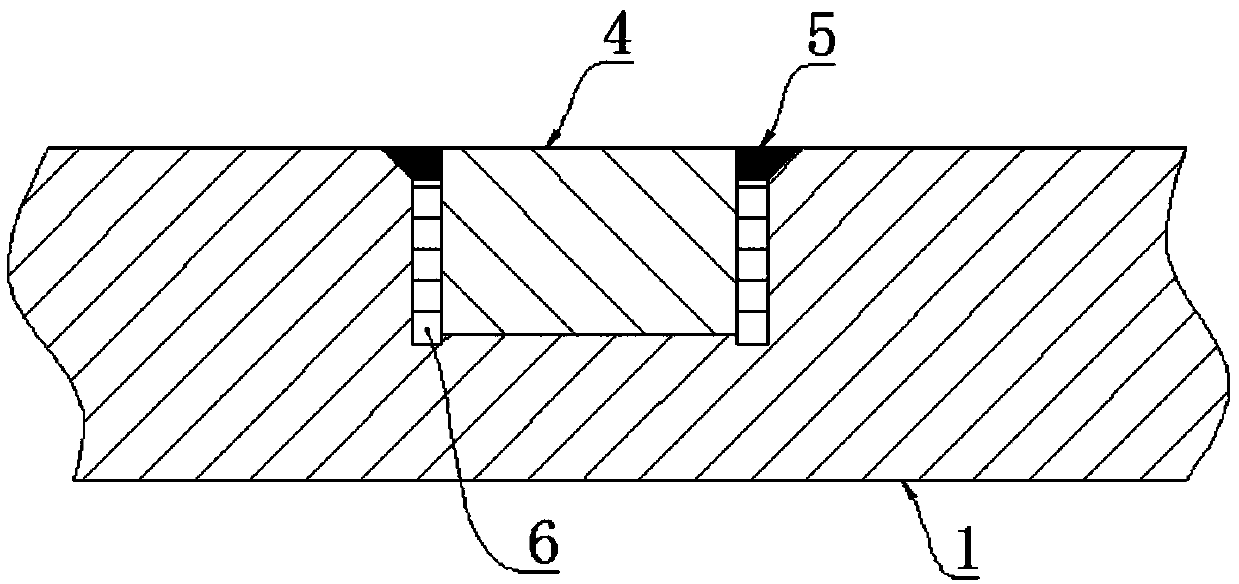

[0045] S5. Initial leveling: milling off the part of the filling part 4 that exceeds the surface of the base material 1, and reserve a margin for subsequent processes;

[0...

Embodiment 2

[0054] A method for repairing threaded blind holes with inserts, comprising the steps of:

[0055] S1. Reaming and eliminating defects: expand the threaded hole A2 to be repaired to the pre-designed insert size, eliminate the defective part, and spot-face a 60° chamfer 3 on the top edge of the threaded hole A2;

[0056] S2. Prepare filler: select the same or similar material as the base material 1, and turn out filler 4 that is compatible with the threaded hole A2;

[0057] S3. Filling the threaded hole: apply high-strength thread-locking glue on the 4 sides of the filler, and then assemble it into the threaded hole A2;

[0058] S4. Welding: welding the filler 4 at the chamfer 3 according to the welding parameters, and welding the chamfer 3 completely, and controlling the welding deformation during the welding process;

[0059] S5. Initial leveling: milling off the part of the filling part 4 that exceeds the surface of the base material 1, and reserve a margin for subsequent ...

Embodiment 3

[0066] A method for repairing threaded blind holes with inserts, comprising the steps of:

[0067] S1. Reaming and eliminating defects: expand the threaded hole A2 to be repaired to the pre-designed insert size, eliminate the defective part, and spot-face a 45° chamfer 3 on the top edge of the threaded hole A2;

[0068] S2. Prepare filler: select the same or similar material as the base material 1, and turn out filler 4 that is compatible with the threaded hole A2;

[0069] S3. Filling the threaded hole: apply high-strength thread-locking glue on the 4 sides of the filler, and then assemble it into the threaded hole A2;

[0070] S4. Welding: welding the filler 4 at the chamfer 3 according to the welding parameters, and welding the chamfer 3 completely, and controlling the welding deformation during the welding process;

[0071] S5. Initial leveling: milling off the part of the filling part 4 that exceeds the surface of the base material 1, and reserve a margin for subsequent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com