Sucking disc type robot used for goods grabbing and placing

A suction cup type and robot technology, which is applied in the direction of manipulators, claw arms, chucks, etc., can solve the problems of easily scratching the surface of goods, injuring staff, and high labor intensity, so as to achieve high use value, avoid scratches or damage, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

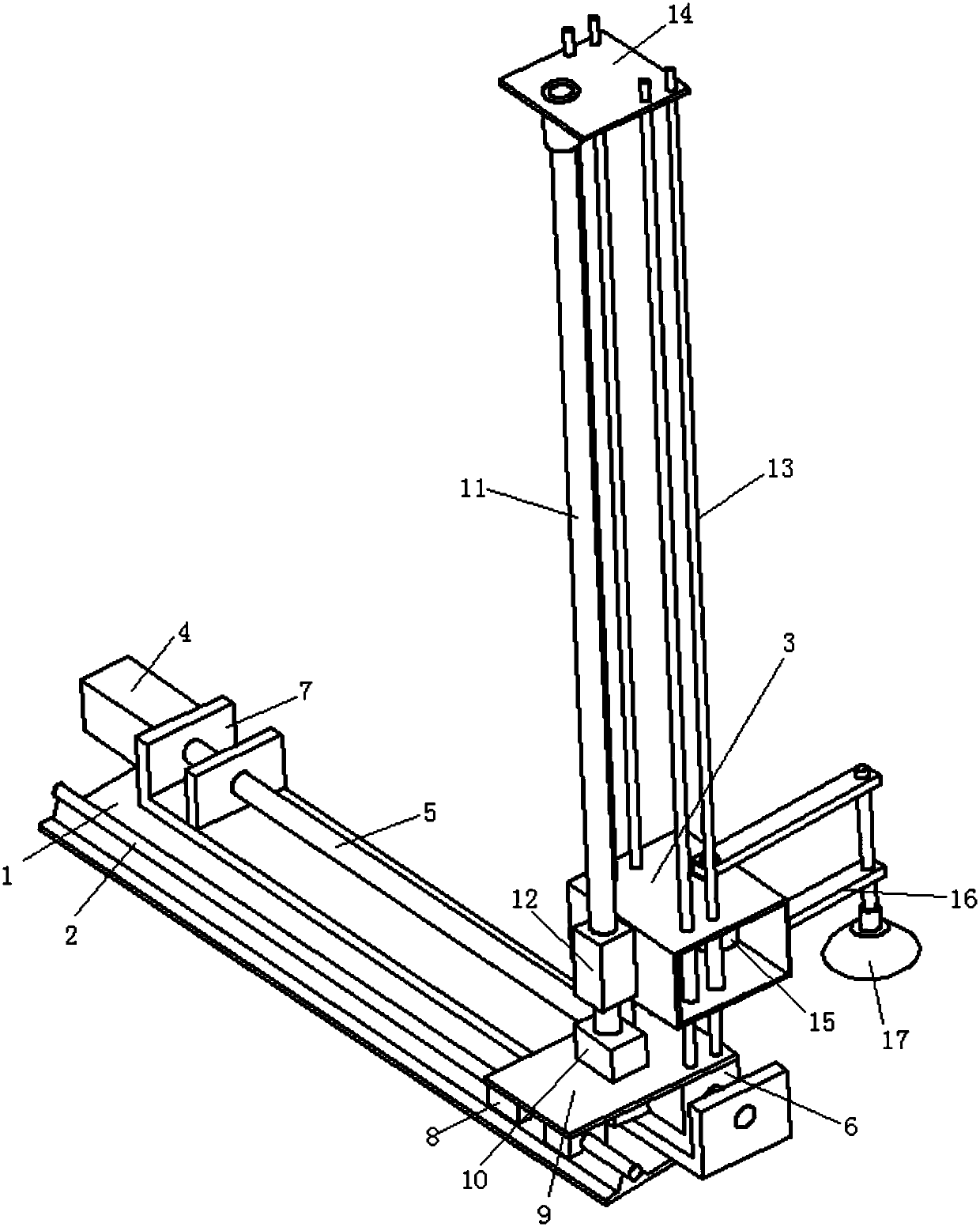

[0013] Attached below figure 1 An embodiment of the present invention is described.

[0014] A sucker-type robot used for grabbing and placing goods has a base body 1, a guide rail 2 is provided on one side of the upper end surface of the base body 1, and a traverse device installed on the other side of the upper end surface of the base body 1 passes through a connecting plate 9 and The slide block 8 that is located on the guide rail 2 is connected, and the described traversing device drives the connecting plate 9 and the elevating device located on the connecting plate 9 to move along the length direction of the seat body 1, and the elevating device is provided with a mounting base 3 and used The angle-adjustable grabbing device for grabbing goods is arranged on the mounting base 3, and the angle-adjustable grabbing device and the grabbed goods are moved up and down along the length direction of the lifting device through the lifting device. Both the device and the angle-adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com