Full-automatic two-direction pasted glass adhesive tape production line

A glass glue, fully automatic technology, applied in the field of machinery and equipment, can solve the problems of reducing the quality of glue strips, easy to produce wrinkles, skew, etc., and achieve the effect of continuous glue strip process, accurate positioning and high quality of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

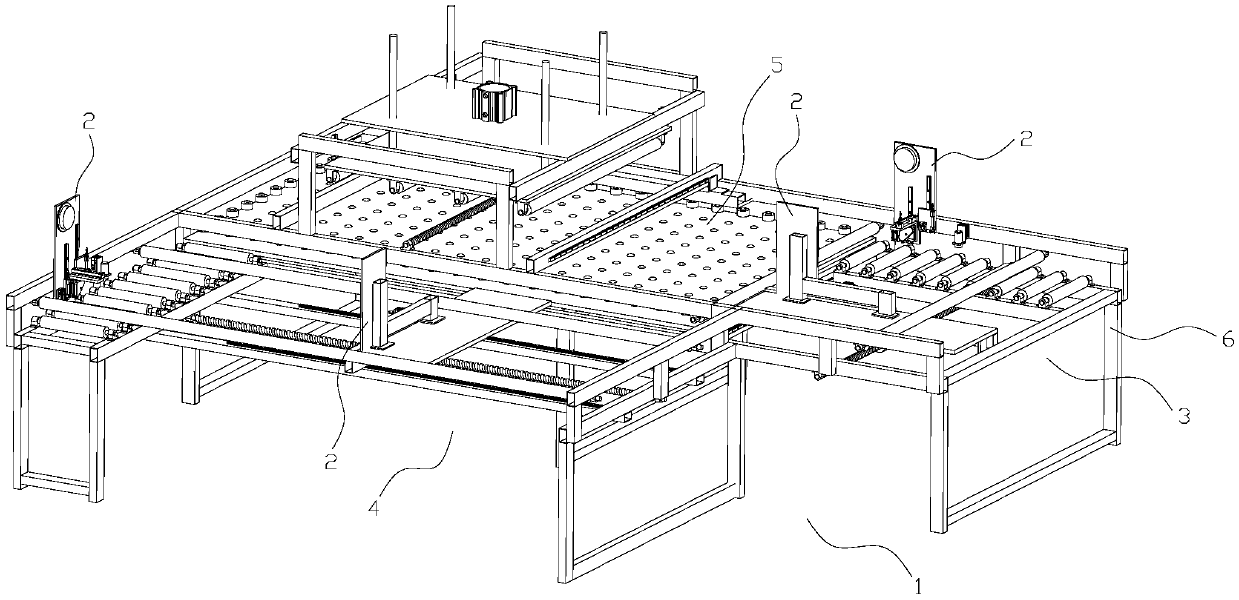

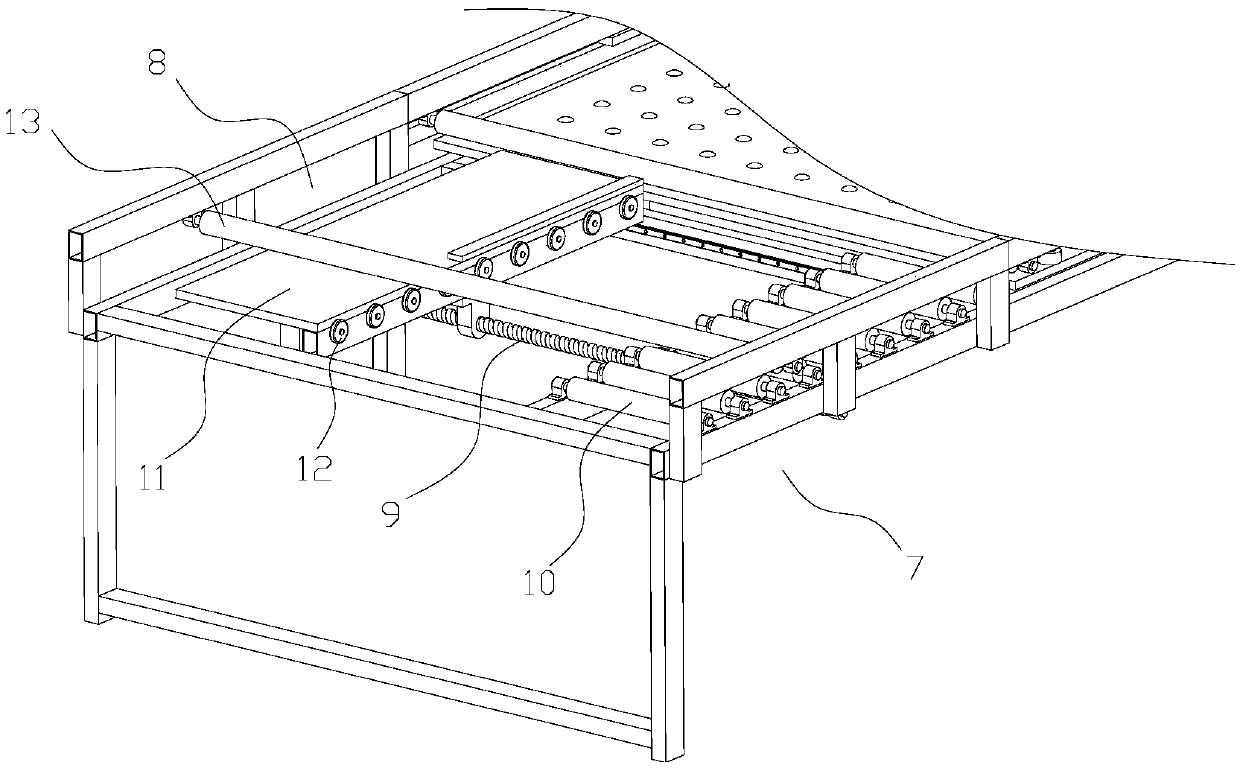

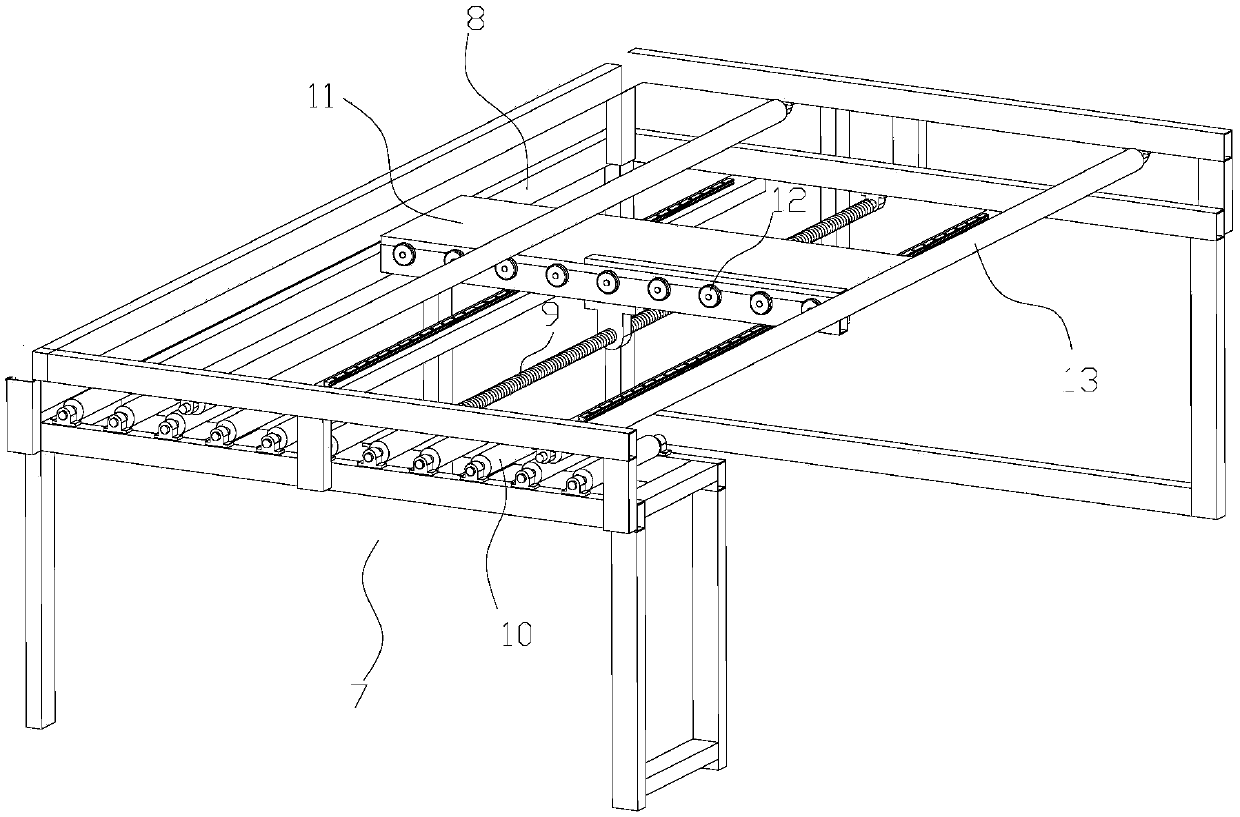

[0068] see Figure 1 to Figure 5 , the embodiment of the present invention provides a fully automatic two-way glued glass production line, including a conveying device 1, and a glued strip device 2 arranged on the conveying device 1; the conveying device 1 includes a first conveying line connected in an L shape 3 and the second conveying line 4, and the universal slide table 5 connected between the first conveying line 3 and the second conveying line 4; the conveying directions of the first conveying line 3 and the second conveying line 4 are orthogonal to each other, and The first conveying line 3 and the second conveying line 4 are provided with along the conveying direction and are installed with for providing the power group of conveying power; The starting end is connected, and the universal slide table 5 is provided with a first conveying manipulator 19 driven along the direction of the first conveying line 3, and a second conveying manipulator 20 driven along the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com