Wine bottle cap spurted code reading and recording system

A recording system and coding technology, which is applied in the field of coding reading, can solve the problems such as the feeling of soreness and tiredness in the hands and the inability to meet the needs of use, so as to avoid misleading consumers and improve the quality of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. However, the embodiments may be embodied in various forms and should not be construed as limited to the embodiments mentioned herein. Rather, these embodiments are provided so that the present invention will fully convey the scope of the present invention to those skilled in the art. Also, well-known functions or constructions may not be described or shown in detail to avoid obscuring the subject matter of the present disclosure.

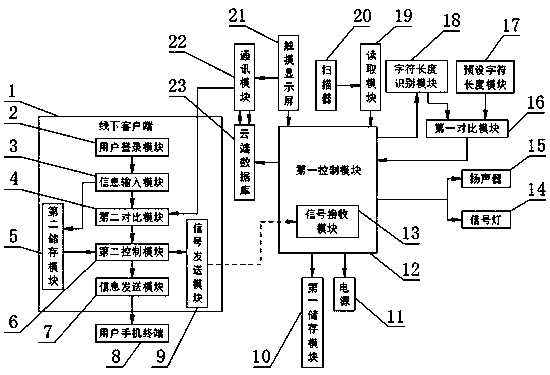

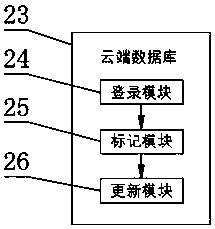

[0024] see Figure 1-2 , the present invention provides a technical solution: a wine bottle cap spray code reading and recording system, comprising: an offline client 1; a power supply 11; a character state comparison module; a first control module 12; an alarm module; and a scanning module , the scanning module includes a scanner 20 and a reading module 19; wherein, the first control module 12 is electrically coupled to the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com