Rapid retreating type conveying machine using servo drive

A servo-driven, fast-rewind technology, used in conveyors, transportation and packaging, etc., can solve problems such as poor stability, fragile product damage, slow transmission speed, etc., and achieve good market application prospects and high use efficiency. , Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

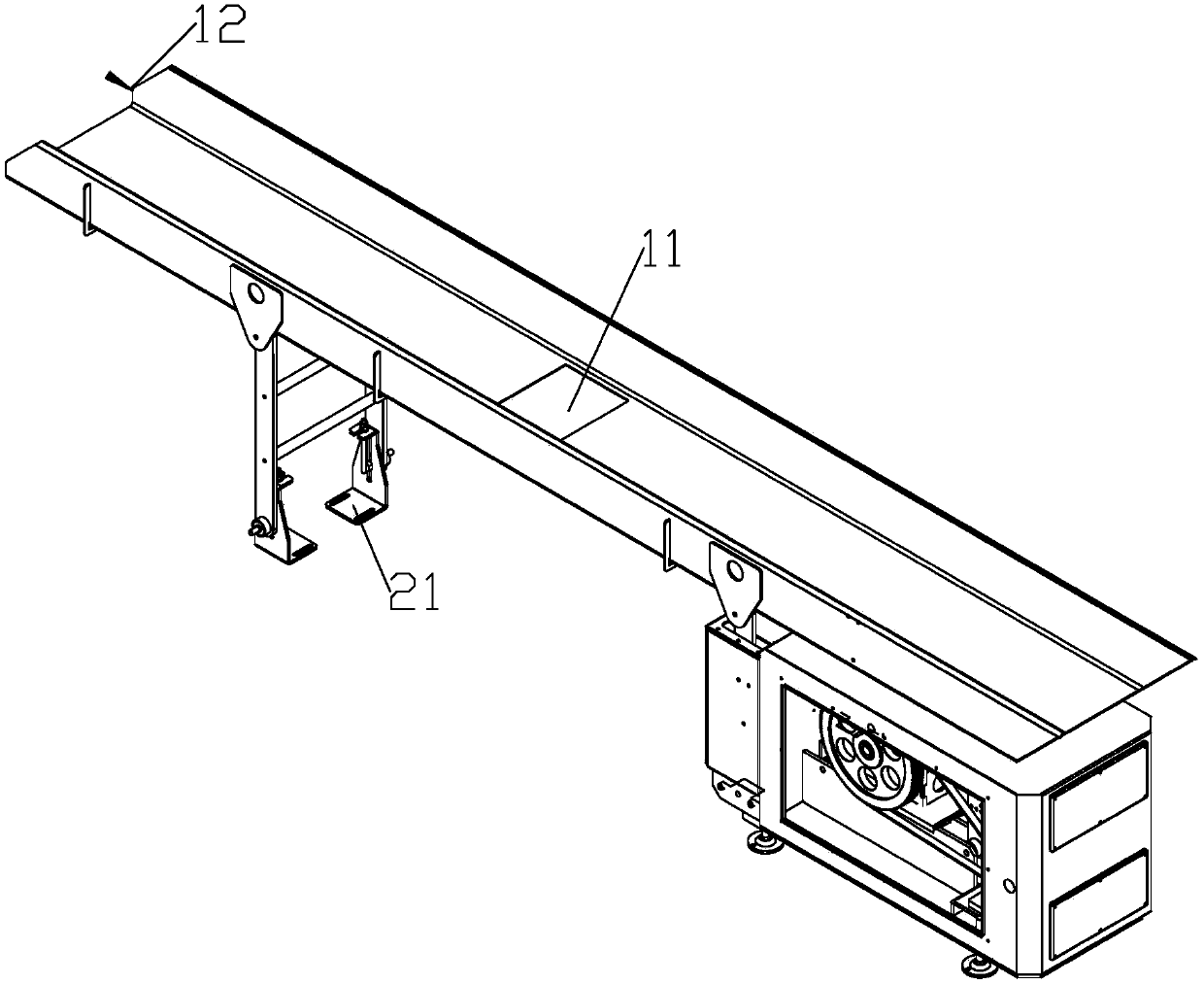

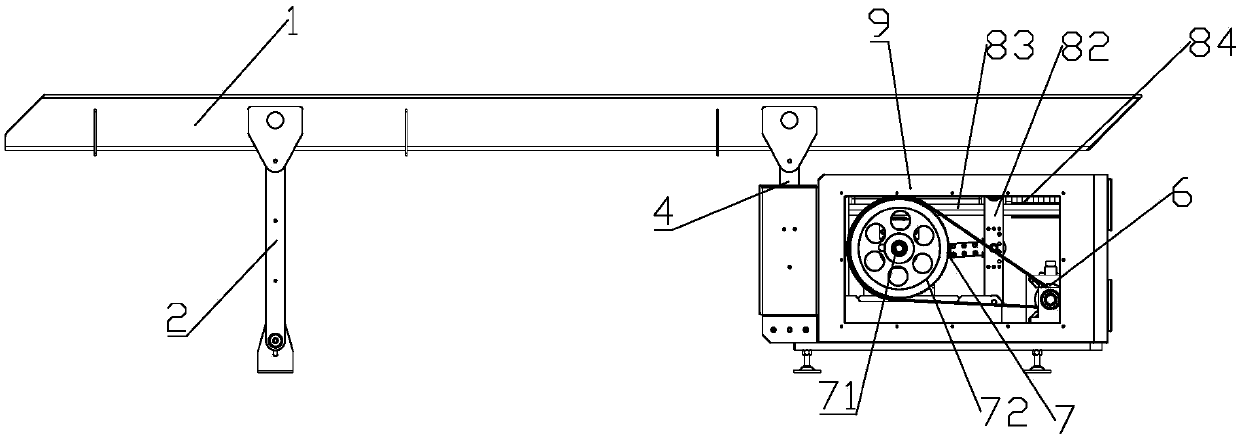

[0022] combine Figure 1-Figure 5 , a fast-reverse conveyor driven by a servo of the present invention includes a conveying trough 1, a supporting leg 2 and a driving device, and the driving device includes a servo motor 6, a closed-loop controlled servo system, a base 3, a driving arm 4, and a bracket 5. The transmission mechanism 7 and the counterweight device 8 arranged on the support 5; the driving arm 4, the support 5 and the servo motor 6 are arranged on the base 3, the transmission mechanism 7 includes a symmetrical double eccentric main shaft 71 and a belt transmission mechanism 72, and the double eccentric The main shaft 71 includes a first eccentric wheel 711 and a second eccentric wheel 712, the first eccentric wheel 711 is connected with the counterweight device 8, the second eccentric wheel 712 is connected with the driving arm 4, and the two ends of the driving arm 4 are respectively connected with the conveying trough disc 1 and The bases 3 are connected; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com