Novel safety elevator

A safety elevator, a new type of technology, applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of easy-to-top wire ropes, falling into wells, unstable operation, etc., and achieve the effect of sufficient power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

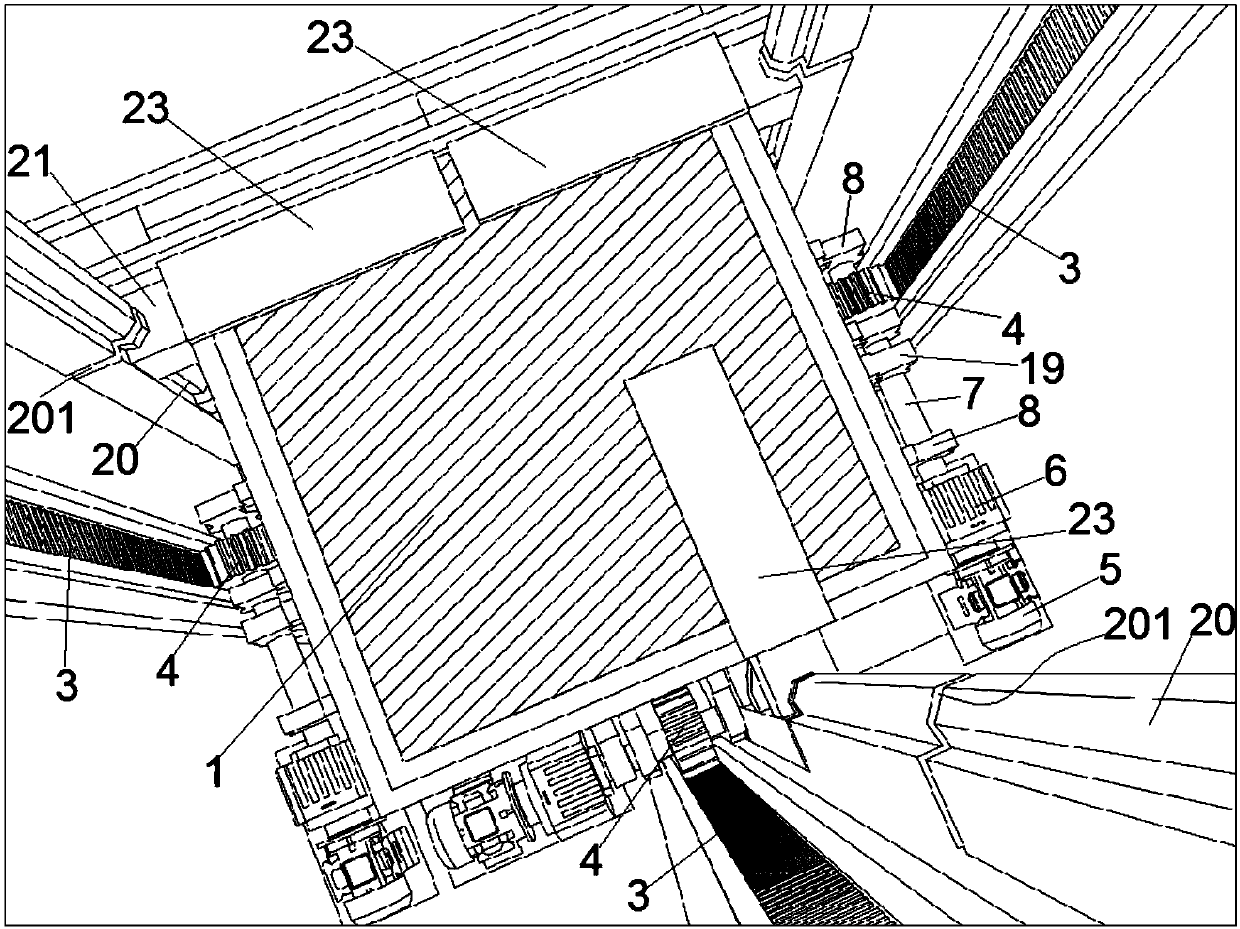

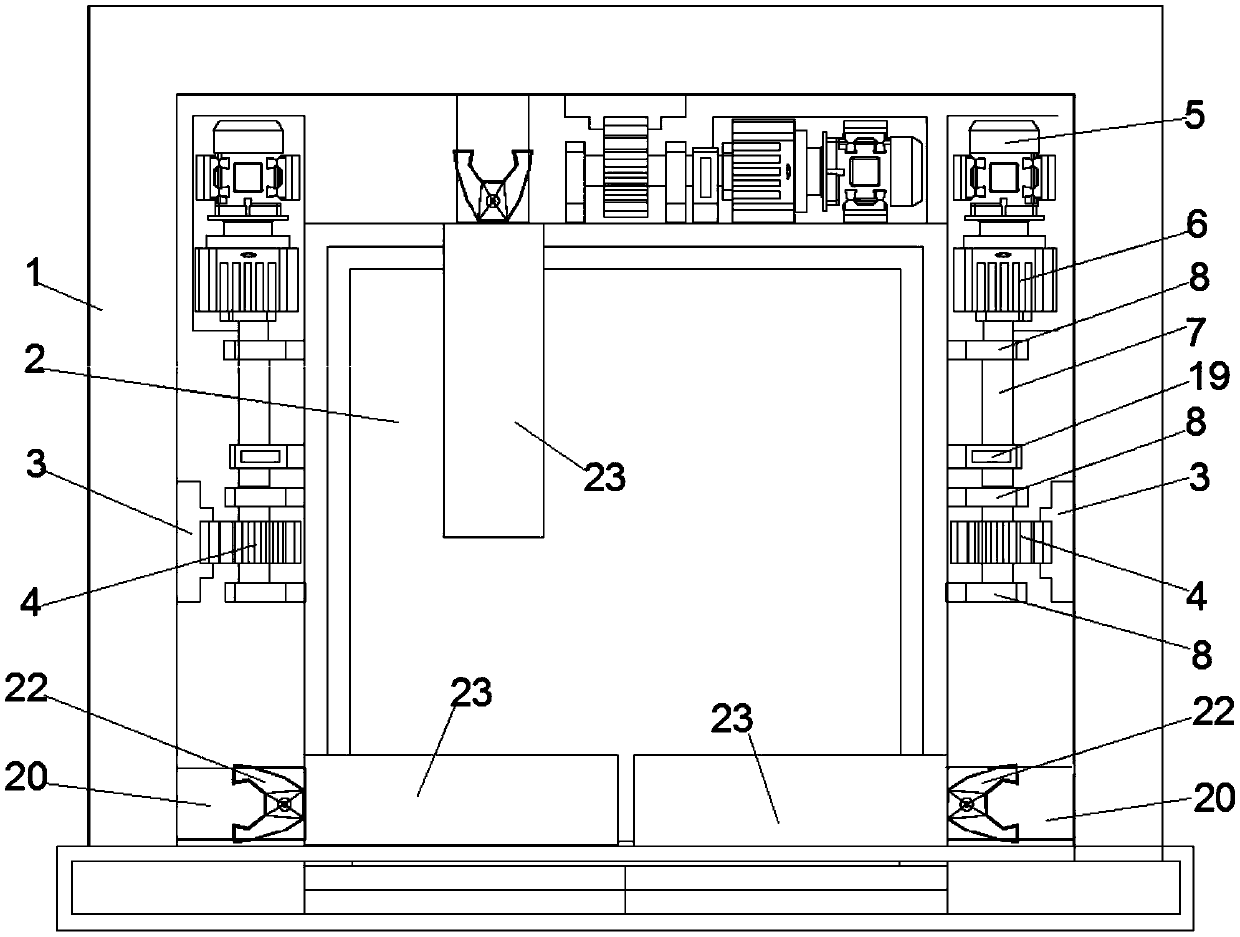

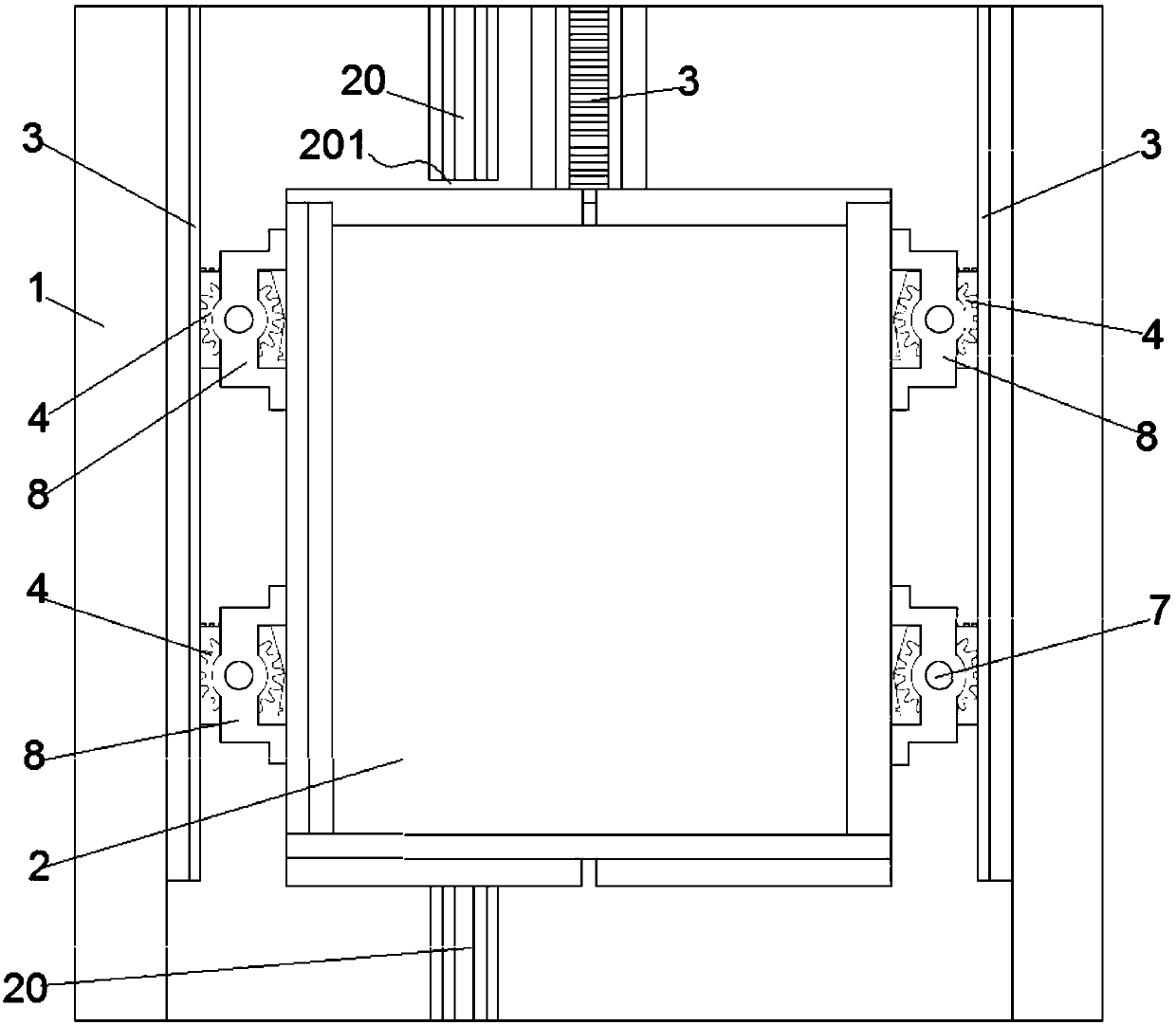

[0049] In this embodiment, a new type of safety elevator includes a car 1, an elevator shaft 2, a rack track 3, a gear 4 and a first power source that drives the gear 4 to rotate, and the above-mentioned car 1 is adapted to the elevator shaft 2, The car 1 can be a square car or a cylindrical car. The above-mentioned car 1 can be vertically lifted in the elevator shaft 2 and is provided with a car door 101 on one side of the car 1. A floor door 211 is provided at a position corresponding to the car door 101 on each floor for people to enter and exit.

[0050] The above-mentioned rack track 3 is installed vertically on the wall of the elevator shaft 2, and the above-mentioned gear 4 is rotatably installed on the outer wall of the side wall of the car 1 through the A bracket 8 and meshed with the above-mentioned rack track 3. The first power source Also be installed on the outer wall of car 1 side wall. When the gear 4 rolls on the rack track 3 like this, it can drive the car 1 ...

Embodiment 2

[0055] This embodiment is an improved implementation of Embodiment 1. This embodiment also includes a steel wire rope system, and one steel wire rope system is respectively provided on the left and right parts of the above-mentioned elevator shaft 2, and the steel wire rope system includes two sets of hoisting wire ropes. 9. Two pull-down wire rope sets 10, two coaxial reversing pulleys 11, two coaxial first reels 13, two coaxial second reels 14 and drive the first reel 13 and the second power source that the second reel 14 rotates synchronously. The above-mentioned second power source, the second reel 14 and the first reel 13 are all installed at the bottom of the elevator shaft 2, and the above-mentioned reversing pulley 11 is installed on the top of the elevator shaft through the rotation of the B bracket 12 .

[0056] Two pull-down wire ropes 10 are respectively wound on two first drums 13 and the free ends of the two pull-down wire ropes 10 are respectively connected to t...

Embodiment 3

[0060] This embodiment serves as a more optimal implementation of Embodiment 2. Both the first power source and the second power source in this embodiment include a motor 5 , a reducer 6 and a rotating shaft 7 connected in sequence. Specifically, the motor 5 and the reducer 6 of the first power source are fixed on the outer wall of the side wall of the car 1, and the rotating shaft 7 of the first power source is connected to the power output end of the reducer 6 of the first power source and passed through A The bracket 8 is rotatably installed on the outer wall of the side wall of the car 1, the gear 4 is installed on the rotating shaft 7 and can rotate synchronously with it; the motor 5 and the reducer 6 of the second power source are fixed at the bottom of the elevator shaft 2, and the second The rotating shaft 7 of the two power sources includes the A rotating shaft 15 connected to the power output end of the reducer and the B rotating shaft 16 meshing with the A rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com