Rigid combination rod shutter blade mechanisms capable of achieving twisted deformation and operating system

A technology of distortion and operation system, applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of unable to provide an ideal balanced indoor light environment, lack of durability and wind resistance, difficult to achieve horizontal layout, etc. To meet the needs of lighting and shading, the technical means are simple and easy to implement, and it is easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

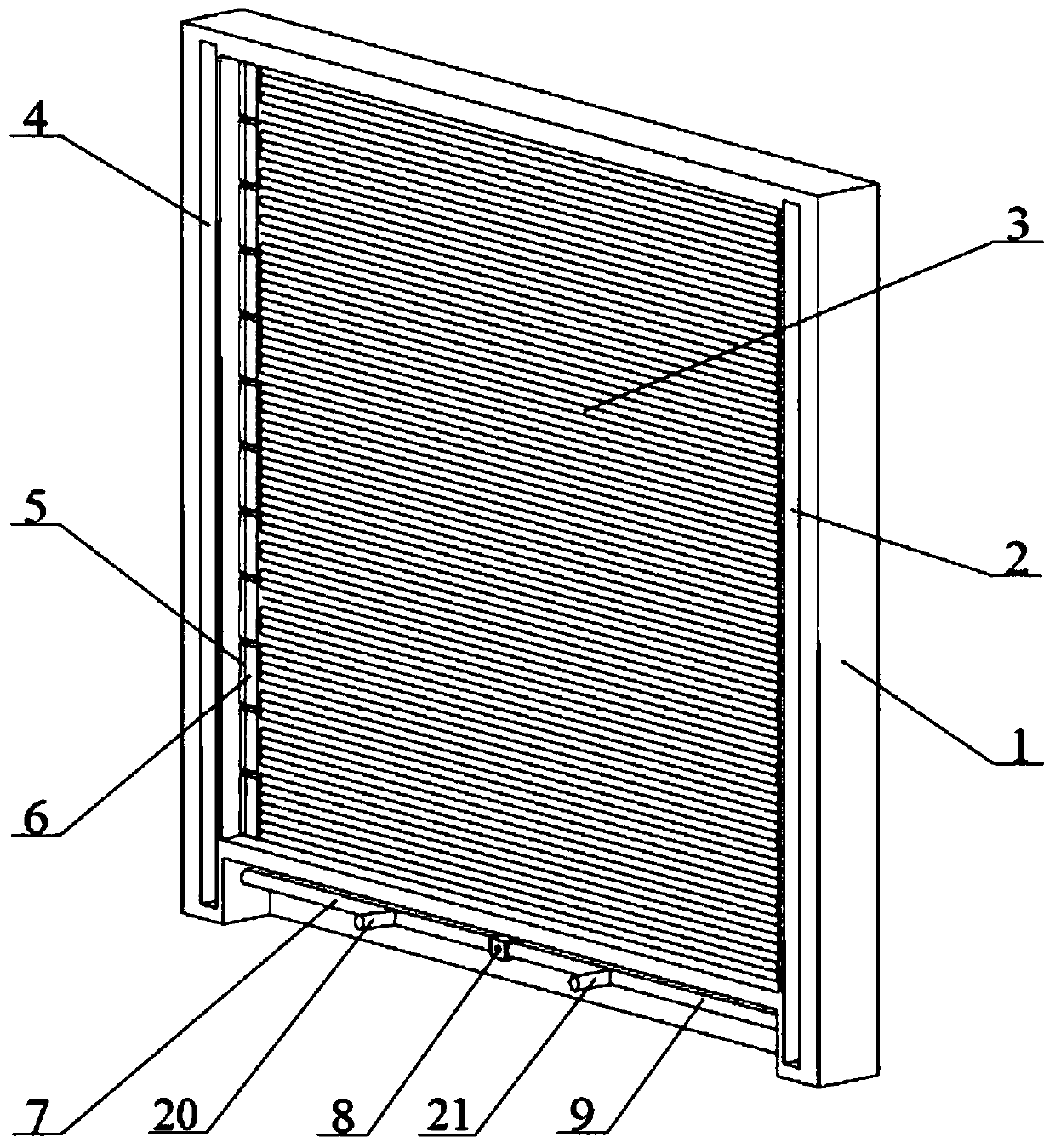

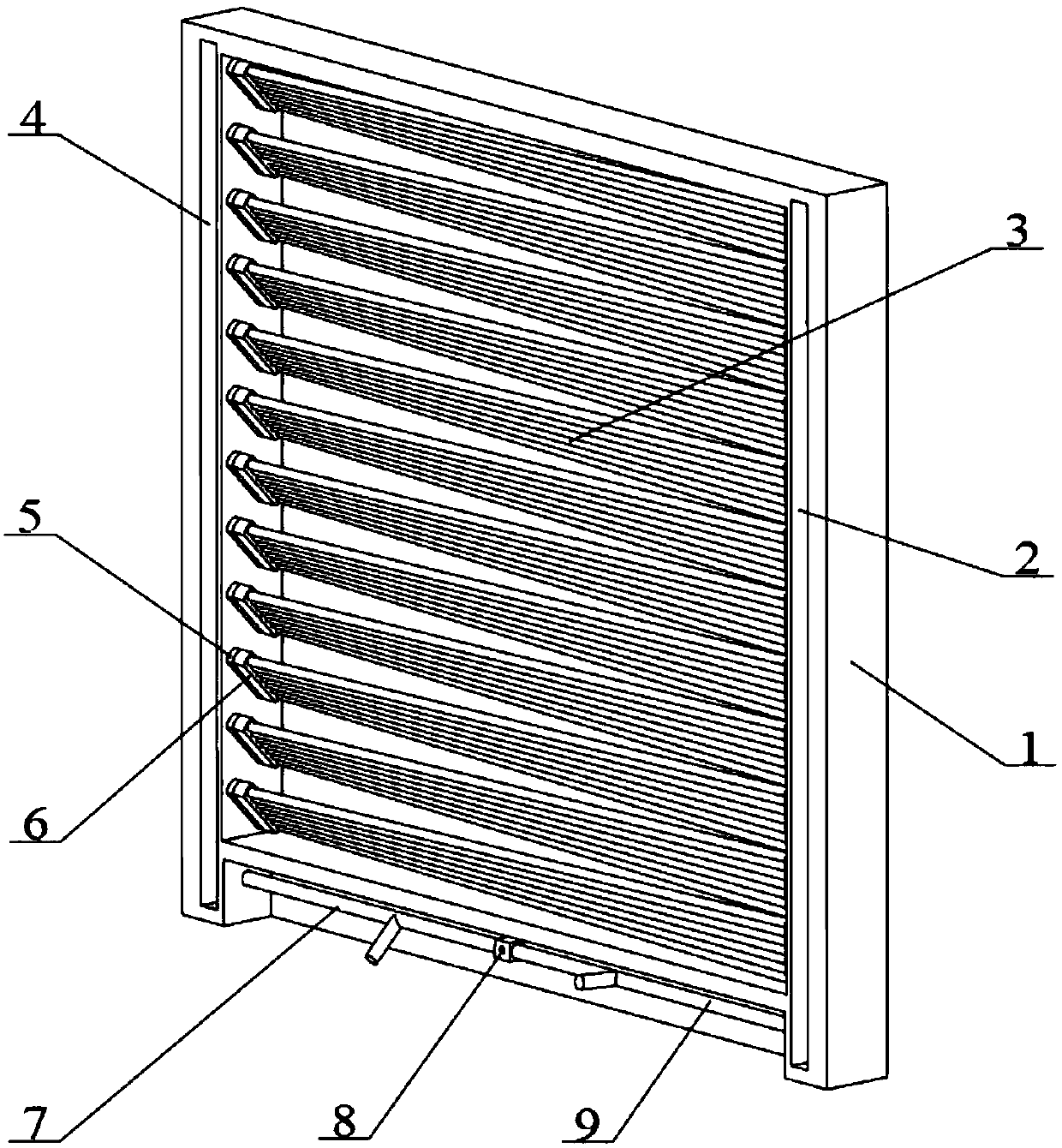

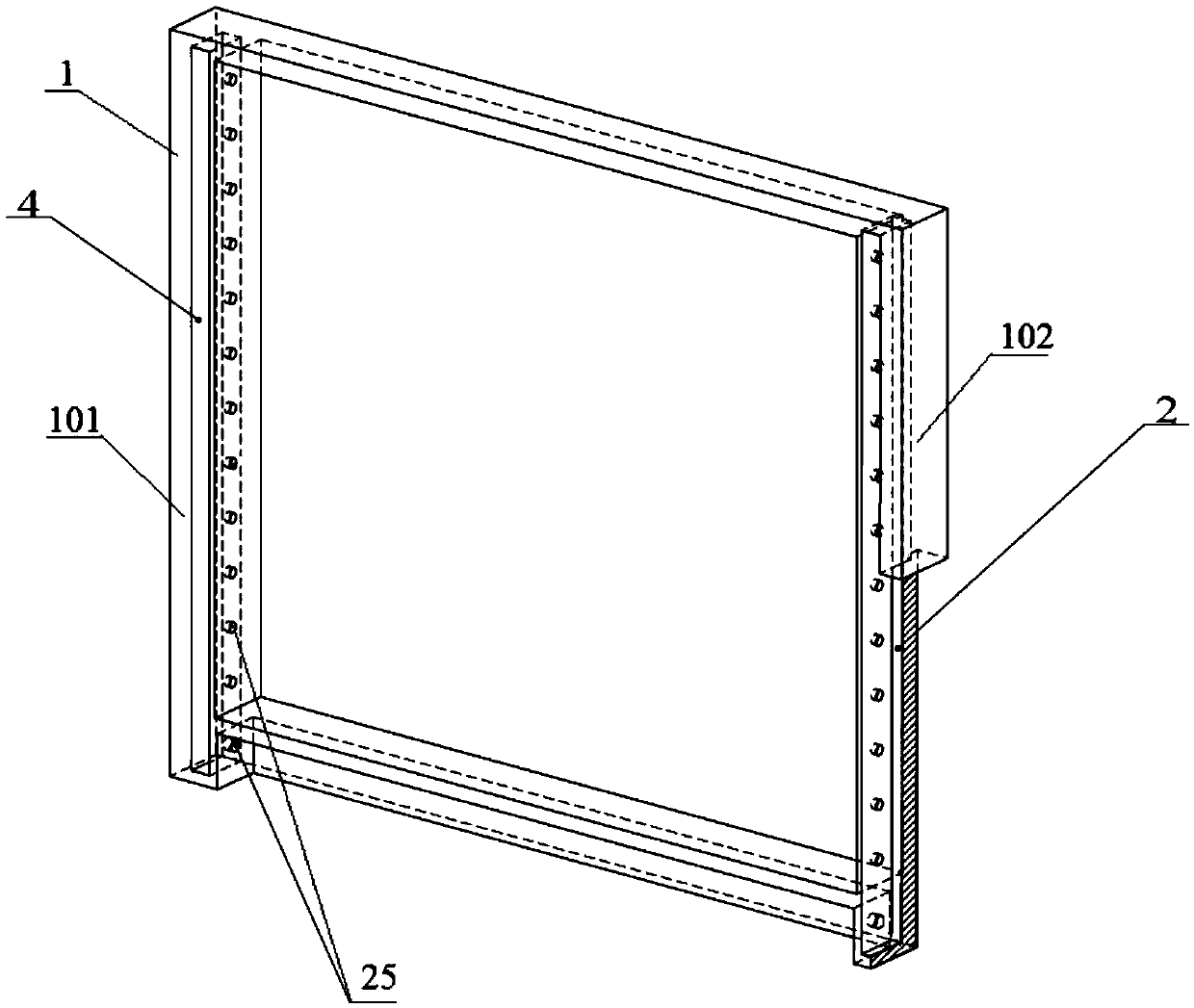

[0042] The present invention discloses a rigid composite rod shutter blade mechanism 3 capable of realizing twisting and deformation. The blade mechanism 3 includes a pair of fixed plates 6, and a plurality of variable lengths are arranged in parallel between the pair of fixed plates 6 The blade rods 18 are movably connected between each blade rod 18 and the fixed plate 6, wherein:

[0043] An end plate 5 is provided on the side of the pair of fixed plates 6, and a rotating shaft 12 is installed on the end plate 5.

[0044] Such as Figure 7 As shown in (a) and (b), the blade mechanism 3 of the present invention adopts a combined structure design. Each blade mechanism 3 includes multiple blade rods 18, and each blade rod 18 is not only adjustable in length, but also fixed A movable link is also adopted between the plates 6 so that the end of the blade rod 18 can rotate relative to the fixed plate 6. With this structural design, the blade mechanism 3 can not only rotate as a whole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com