Self-adjusting type pipeline robot and working method in pipeline thereof

A pipeline robot and self-adjusting technology, applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the problems of poor adaptability, changes, single work goals, etc., to improve work efficiency, strong stability, The effect of enhancing the adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

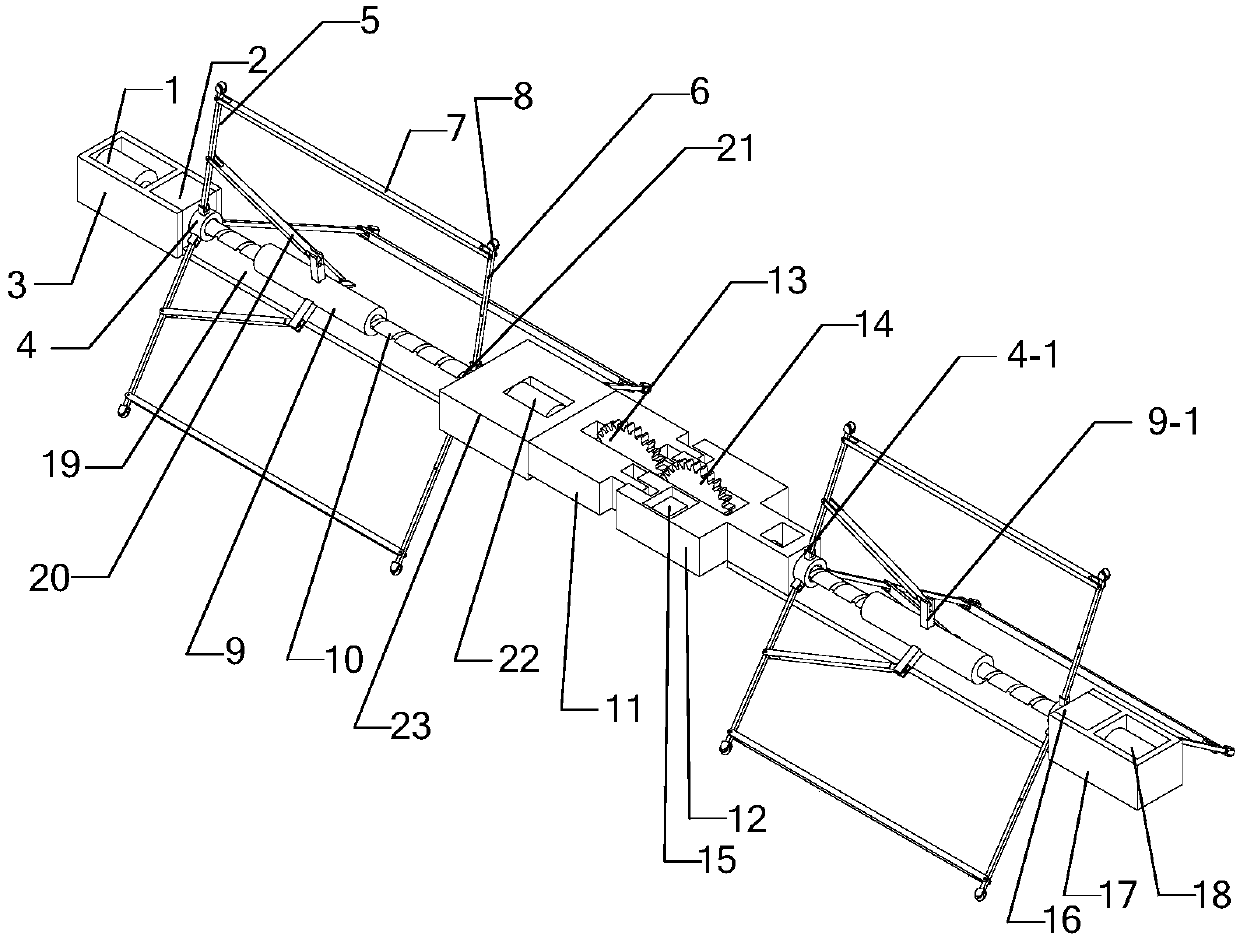

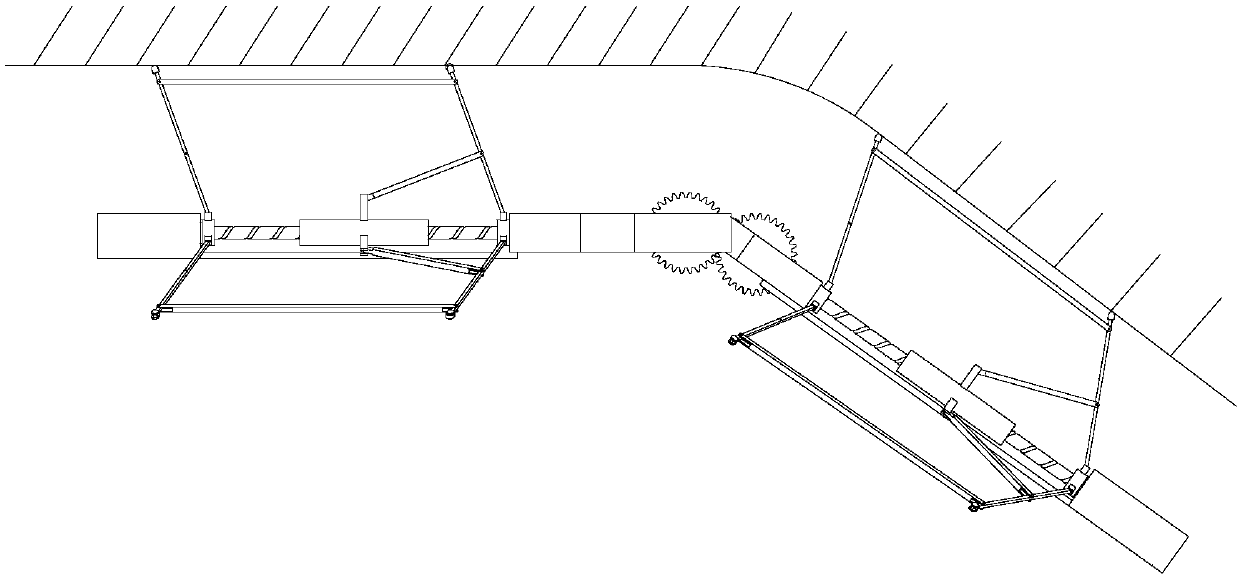

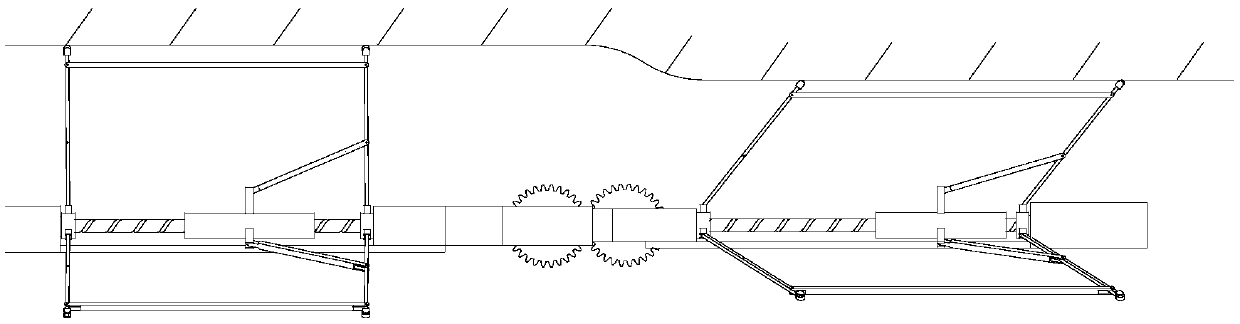

[0022] Such as figure 1 , 2 As shown in and 3, a self-adjusting pipeline robot includes a main body one, a main body two, a camera and a control chip. Main body one includes motor one 1, mounting base one 2, housing one 3, adjustment unit one, rotating base one 11, gear one 13, connecting frame 19, motor four 22, mounting base three 23 and motor five; main body two includes motor Two 18, shell two 17, connecting frame 19, adjustment unit two, installation seat two 16, rotating seat two 12, motor three 15 and gear two 14; the structure of adjustment unit 1 and adjustment unit 2 is exactly the same, including joint 1 4. Joint two 21, lead screw 10, nut seat 9, four-bar mechanism and roller 8; joint one 4 and joint two 21 are provided with three joints one 4-1 uniformly distributed in the circumferential direction, each of joint one 4 The hinge part 1 4-1 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com