Power-closed small angle intersecting shaft gear test bench

A closed, intersecting axis technology, used in the testing of mechanical components, the testing of machine/structural components, instruments, etc., can solve problems affecting meshing performance, installation distance error, axis angle error, etc., and achieve reasonable and reliable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

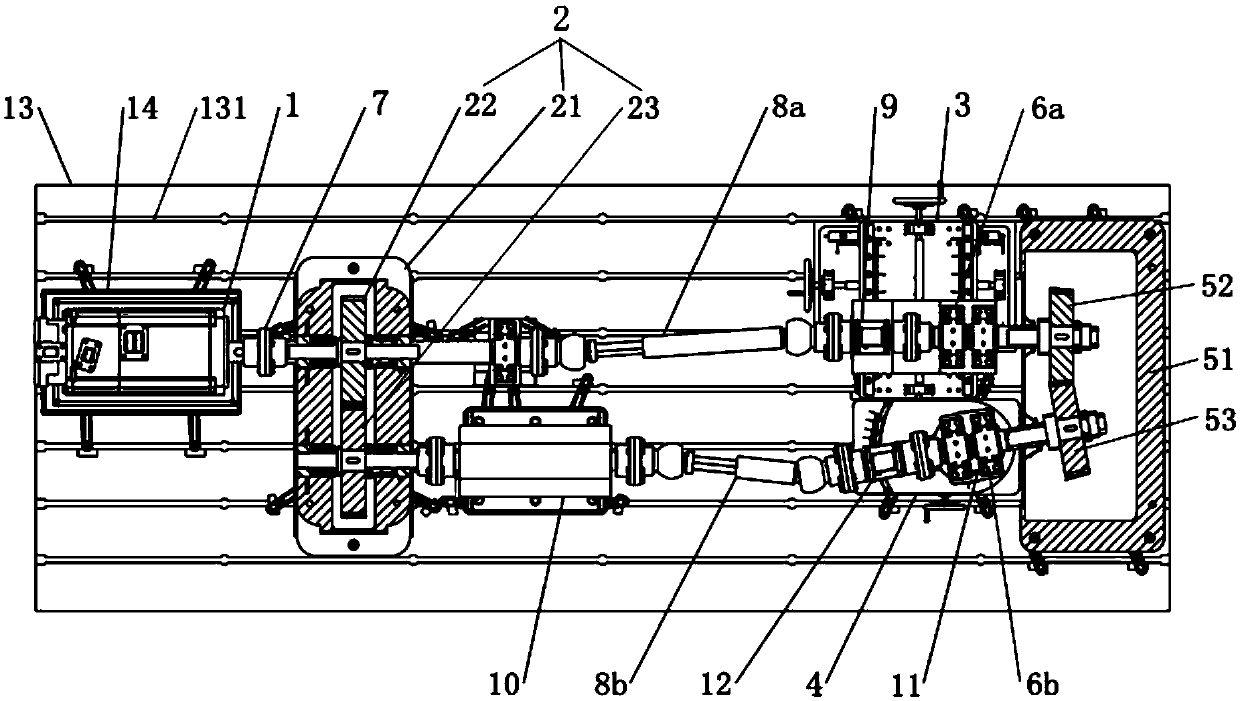

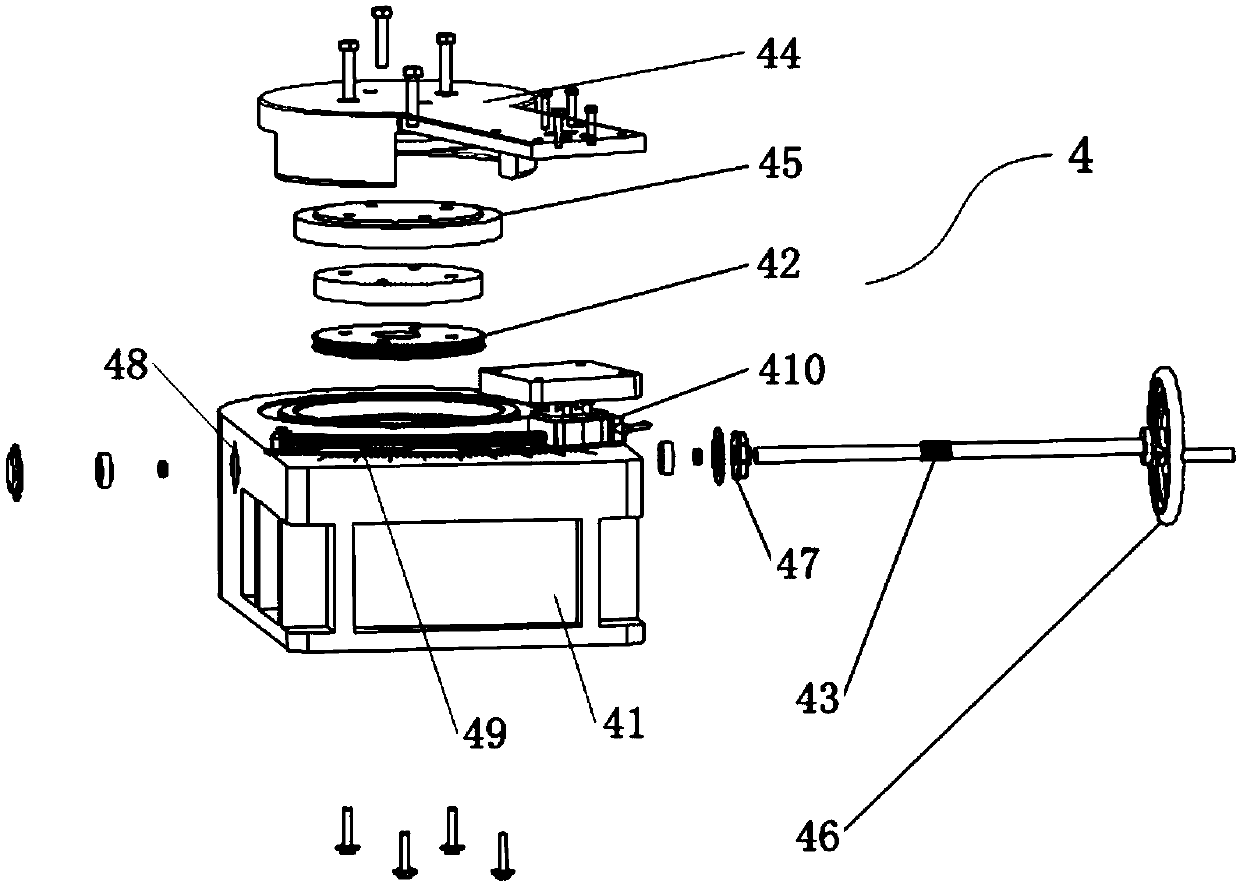

[0019] As shown in the figure, a power-enclosed small angle intersecting shaft gear test bench includes a motor 1 , an auxiliary gearbox 2 , a moving platform 3 , a rotating platform 4 and a test gearbox 5 .

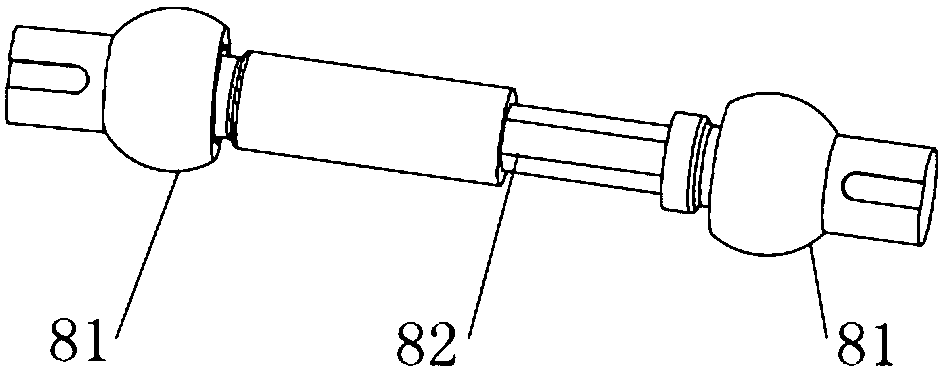

[0020] Specifically, the auxiliary gear box 2 is mainly composed of a box body I21 and helical cylindrical gears meshing with each other. The two helical toothed cylindrical gears are respectively used as the auxiliary gear I22 and the auxiliary gear II23. The auxiliary gear I22 and the auxiliary gear II23 are symmetrically arranged on the box I21. The test gear box 5 includes a box body III51 and a test gear I52 and a test gear II53 arranged in the box body III51 and meshing with each other.

[0021] The mobile platform 3 is a cross slide, including two mobile plates 31, and the tops of the two mobile plates 31 are provided with rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com