Liquid crystal display panel and liquid crystal display device

A liquid crystal display panel, liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of slow liquid crystal response speed, image display stuck, affecting display quality, etc., to increase transmittance and reduce response time. , Improve the effect of screen display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

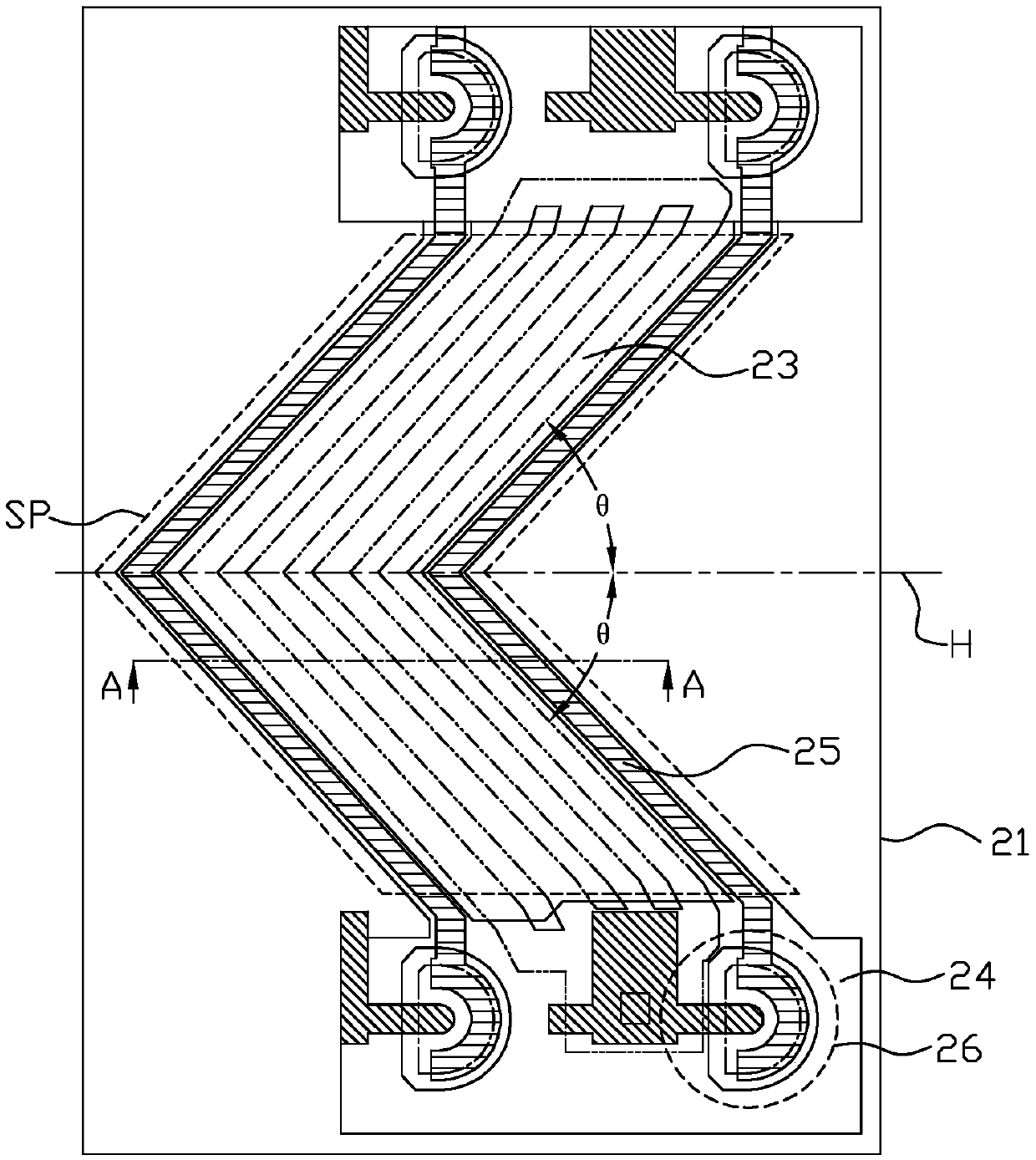

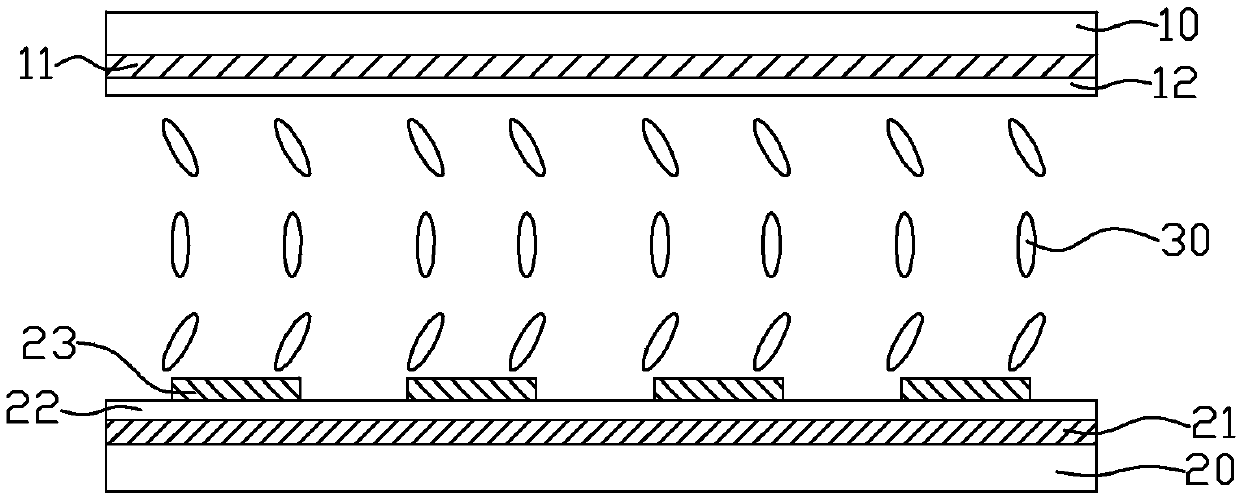

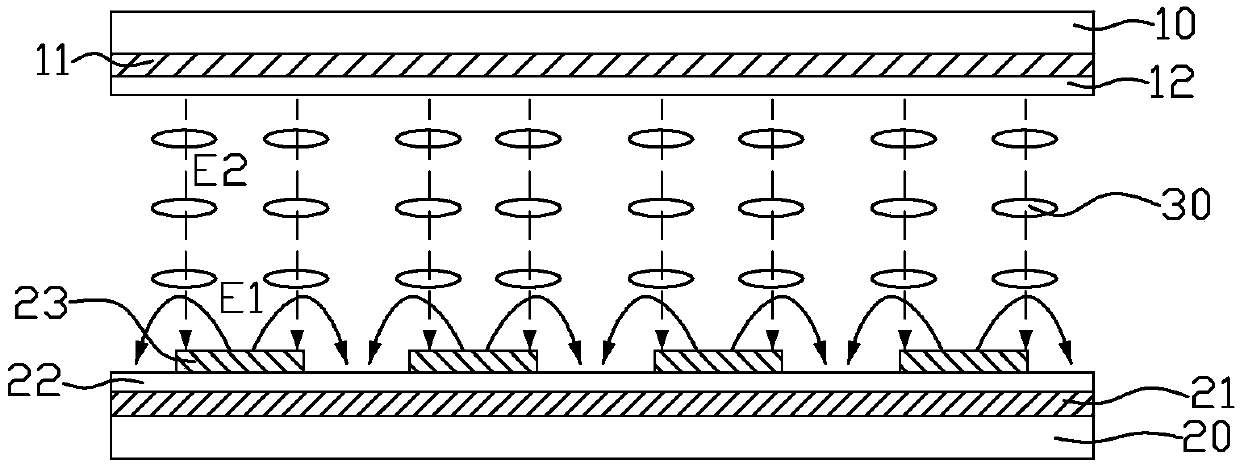

[0029] Such as Figure 1 to Figure 4 As shown, a liquid crystal display panel provided by the present invention includes a first substrate 10 , a second substrate 20 opposite to the first substrate 10 , and a liquid crystal layer 30 between the first substrate 10 and the second substrate 20 . The first substrate 10 can be a substrate made of glass, acrylic, polycarbonate and other materials. In this embodiment, the first substrate 10 is a glass substrate, and the second substrate 20 is a thin film transistor array substrate. The liquid crystal layer 30 adopts positive liquid crystal molecules, that is, liquid crystal molecules with positive dielectric anisotropy, and the positive liquid crystal molecules adopt vertical alignment (that is, the long axis of the positive liquid crystal molecules is 70°-90° to the first substrate 10 ), In this embodiment, the initial state of the positive liquid crystal molecules is perpendicular to the first substrate 10 and the second substrate ...

Embodiment 2

[0040] Such as Figure 6 As shown, the liquid crystal display panel provided by Embodiment 2 of the present invention is the same as Embodiment 1 ( figure 1 ) in the structure and working principle of the liquid crystal display panel are basically the same, the difference is that, in this embodiment, each pixel electrode 23 is a ">" shape structure, which is the pixel with a "<" shape structure in the first embodiment The directions of the electrodes 23 are reversed, so that multiple implementations can be selected while achieving the purpose of the present invention.

[0041] Those skilled in the art should understand that the remaining structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0043] Such as Figure 7 and Figure 8 As shown, the liquid crystal display panel provided by Embodiment 3 of the present invention is the same as Embodiment 1 ( figure 1 and Figure 4 ) in the liquid crystal display panel are basically the same in structure and working principle, the difference is that in this embodiment, the auxiliary electrode 11 is a planar structure arranged on the entire surface, and the common electrode 21 and the pixel electrode 23 are all with slits Comb structure, so that multiple implementation options are available while realizing the purpose of the present invention.

[0044] Those skilled in the art should understand that the remaining structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com